High-strength pearl bone-china blank and preparation method thereof

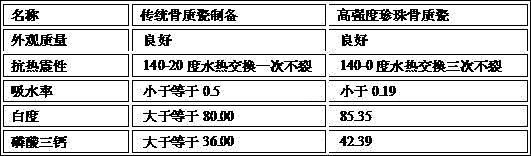

A bone china, high-strength technology, applied in the field of bone china raw materials, can solve the problems of excessive softness, easy burning and cracking, and increase the difficulty of burning, and achieve the effect of reducing difficulty and improving hardness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in detail below in conjunction with embodiment.

[0018] A preparation method of a high-strength pearl bone china blank, carried out according to the following steps:

[0019] 1. The ratio of raw materials is calculated according to the following parts by weight:

[0020] Main ingredients: 40 parts of bone carbon, 5 parts of natural pearl particles, 10 parts of quartz, 9 parts of feldspar, 4 parts of Yunnan soil, 4 parts of Taolong soil, 10 parts of Longyan soil, 10 parts of raw sand, 8 parts of Yusi soil, 100 copies in total;

[0021] Additives: 3 parts of plasticizer (accounting for 3% of the total weight of main ingredients), 1 part of oxalic acid (accounting for 2.5% of the weight of bone carbon), 0.02 parts of high-viscosity cellulose (accounting for 0.02% of the total weight of main ingredients), 0.55 parts of sodium humate (accounting for 0.55% of the total weight of main ingredients), a total of 4.57 parts;

[0022] Water: 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com