High-speed coagulation reactor for feed water treatment

A technology of coagulation reactor and water supply treatment, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. Project construction investment, the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

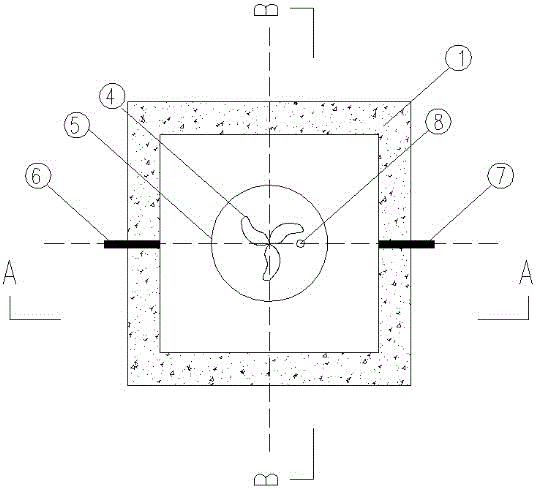

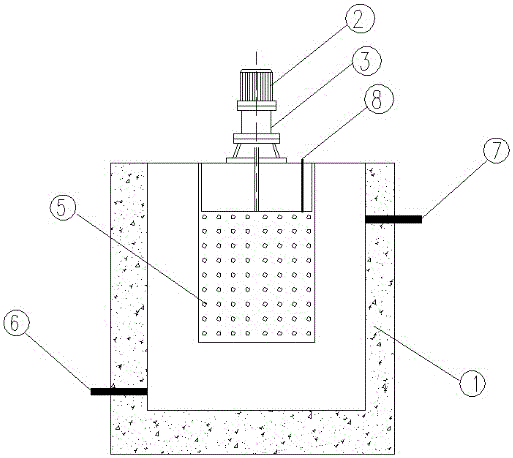

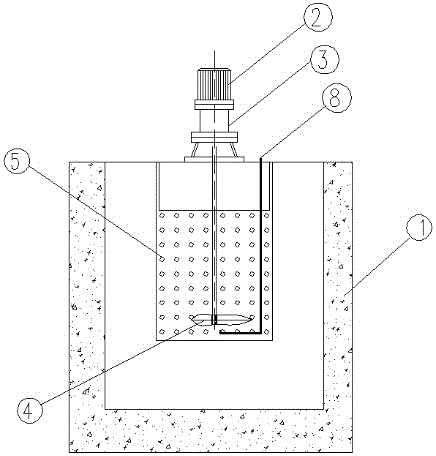

[0024] The agitator 4 adopts a fully submerged vertical installation, the rotating speed is 960r / min, the outer diameter of the paddle is 400mm, and the angle is 15°; the diameter of the spoiler 5 is twice the outer diameter of the paddle of the agitator 4. The mesh on the barrel 5 is a round hole with an opening rate of 70%; the discharge port of the L-shaped feed pipe 8 is placed 15 mm below the blade of the agitator 4 . The source water mixed with polyaluminum chloride enters the high-speed stirring mixing reactor, driven by the driving device, the high-speed stirring equipment stirs the water body, the reaction time is 10s, and then enters the original flocculation tank, sedimentation tank, sand filter in sequence pool.

Embodiment 2

[0026] The agitator 4 adopts a fully submerged vertical installation, the rotating speed is 800r / min, the outer diameter of the paddle is 360mm, and the angle is 20°; the diameter of the spoiler 5 is 2.5 times the outer diameter of the paddle of the agitator 4. The mesh on the barrel 5 is a round hole with an opening ratio of 50%; the discharge port of the L-shaped feed pipe 8 is placed 10 mm below the blade of the agitator 4 . The source water mixed with polyaluminum chloride enters the high-speed stirring mixing reactor. Driven by the driving device, the high-speed stirring equipment stirs the water body. The reaction time is 8s, and then enters the original flocculation tank, sedimentation tank, and sand filter in sequence. pool.

Embodiment 3

[0028] The agitator 4 adopts a fully submerged vertical installation, the rotating speed is 1200r / min, the outer diameter of the paddle is 200mm, and the angle is 5°; the diameter of the spoiler 5 is 3 times the outer diameter of the paddle of the agitator 4. The mesh on the barrel 5 is a round hole with an opening rate of 80%; the discharge port of the L-shaped feed pipe 8 is placed 30 mm below the blade of the agitator 4 . The source water mixed with polyaluminum chloride enters the high-speed stirring mixing reactor, driven by the driving device, the high-speed stirring equipment stirs the water body, the reaction time is 5s, and then enters the original flocculation tank, sedimentation tank, sand filter in sequence pool.

[0029] The high-speed coagulation reactor for water treatment optimizes the mixing from two aspects: increasing the diffusion speed and forming micro-vortex diffusion.

[0030] 1. Increase the speed of diffusion

[0031] The effect of coagulation is cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com