A microstructured surface finishing method, medium and device

A microstructure and finishing technology, which is applied in the direction of surface polishing machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to ensure the uniformity of material removal, destroy fine features, and low material removal rate, and achieve easy digitization Intelligent control, convenient magnetic field force, easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

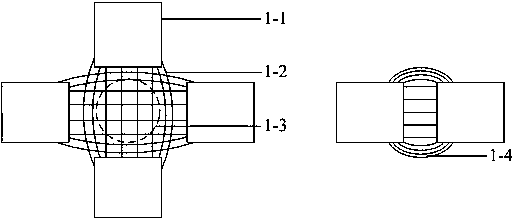

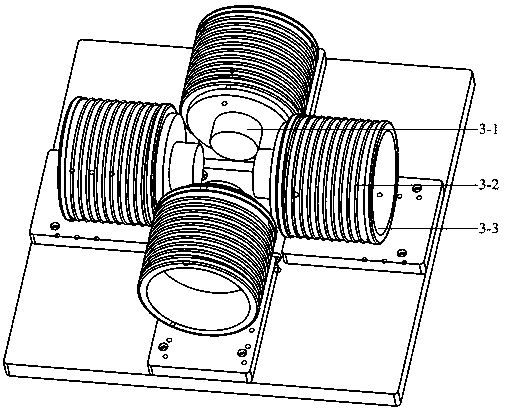

[0022] Embodiment 1: Combining figure 1 , figure 2 , image 3 and Figure 4 It is explained that the surface finishing processing method of a special magnetic shear thickening finishing medium with a finely structured surface described in this embodiment is mainly realized through the following basic steps:

[0023] (1) The electromagnetic coil 3-2 is wound on the coil base 3-3;

[0024] (2) The fine structured parts 2-4 to be smoothed are adjusted to the magnetic field action area through the three-axis precision electric displacement platform 2-6;

[0025] (3) The magnetic field force formed by the electrification of the two pairs of electromagnetic coils 3-2 vertically distributed is applied to the special magnetic shear thickening smoothing medium 4-2;

[0026] (4) The three-axis precision electric displacement platform 2-6 controls the micro-structured parts 2-4 to be smoothed to the magnetic field action area, and realizes the precise positioning of the workpiece by...

specific Embodiment approach 2

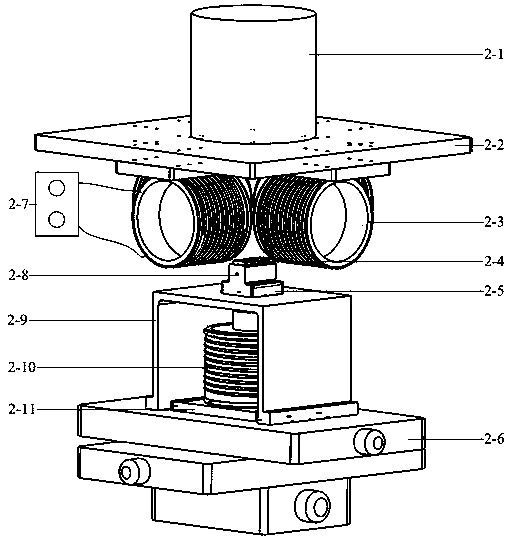

[0030] Specific implementation mode 2: Combining figure 2 and image 3 It is explained that the operating device of the microstructured surface finishing method described in this embodiment includes a magnetic field control unit 2-3, a motion control unit, and an auxiliary coil 2-10 control unit; the magnetic field control unit 2-3 mainly includes a high-speed The spindle 2-1, the spindle connecting plate 2-2, the magnetic conductor 3-1, the electromagnetic coil 3-2, the coil base 3-3, one end of the spindle connecting plate 2-2 is connected to the high-speed spindle 2-1, and the other end is connected to the electromagnetic The coil base 3-3, the electromagnetic coil 3-2 is wound on the electromagnetic coil base 3-3; the motion control unit mainly includes a three-axis precision electric displacement platform 2-6, which provides three freedoms for the micro-structured parts 2-4 The auxiliary coil 2-10 control unit mainly includes the main auxiliary coil 2-10 and the connect...

specific Embodiment approach 3

[0031] Specific implementation three: combination figure 2 Description, the operating device of the microstructured surface finishing method described in this embodiment includes a microstructured part 2-4, a fixture 2-5, and a fixture connecting plate 2-9; the fixture connecting plate 2-9 One end is connected to the clamp 2-5, the other end is connected to the three-axis precision electric displacement platform 2-6, and other components and connection relationships are the same as those of the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com