Anti-corrosion paint spraying maintenance device applicable to oil transferring pipelines of multiple specifications

An anti-corrosion technology for oil pipelines, applied in the direction of spraying devices, liquid spraying devices, and devices for coating liquid on the surface, etc., can solve the problems of heavy workload, uneven painting, low work efficiency, etc., and achieve strong applicability , Improve the quality of spray paint and the effect of good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

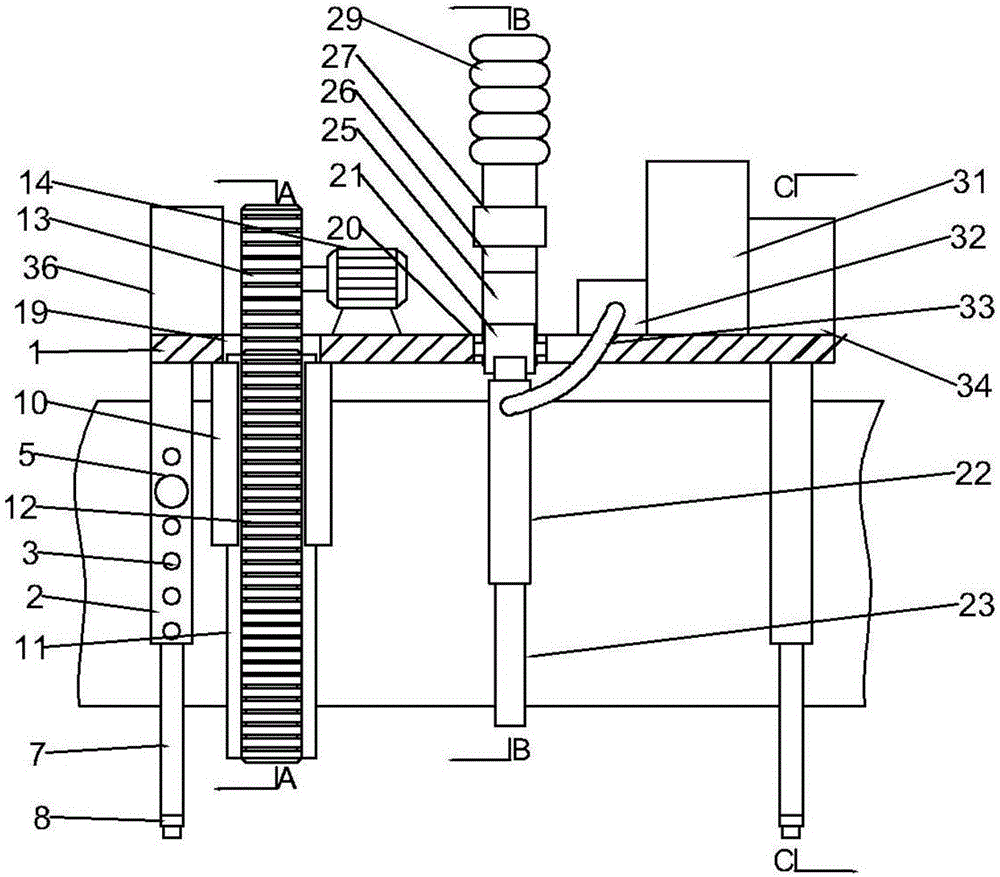

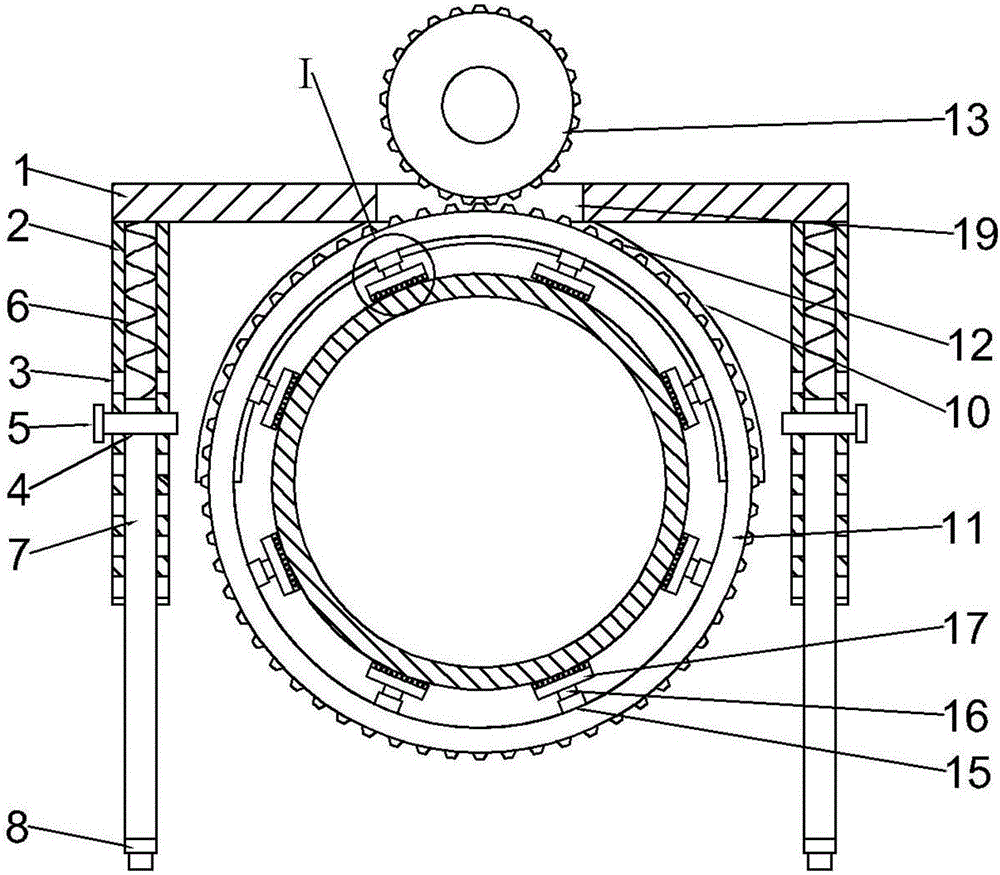

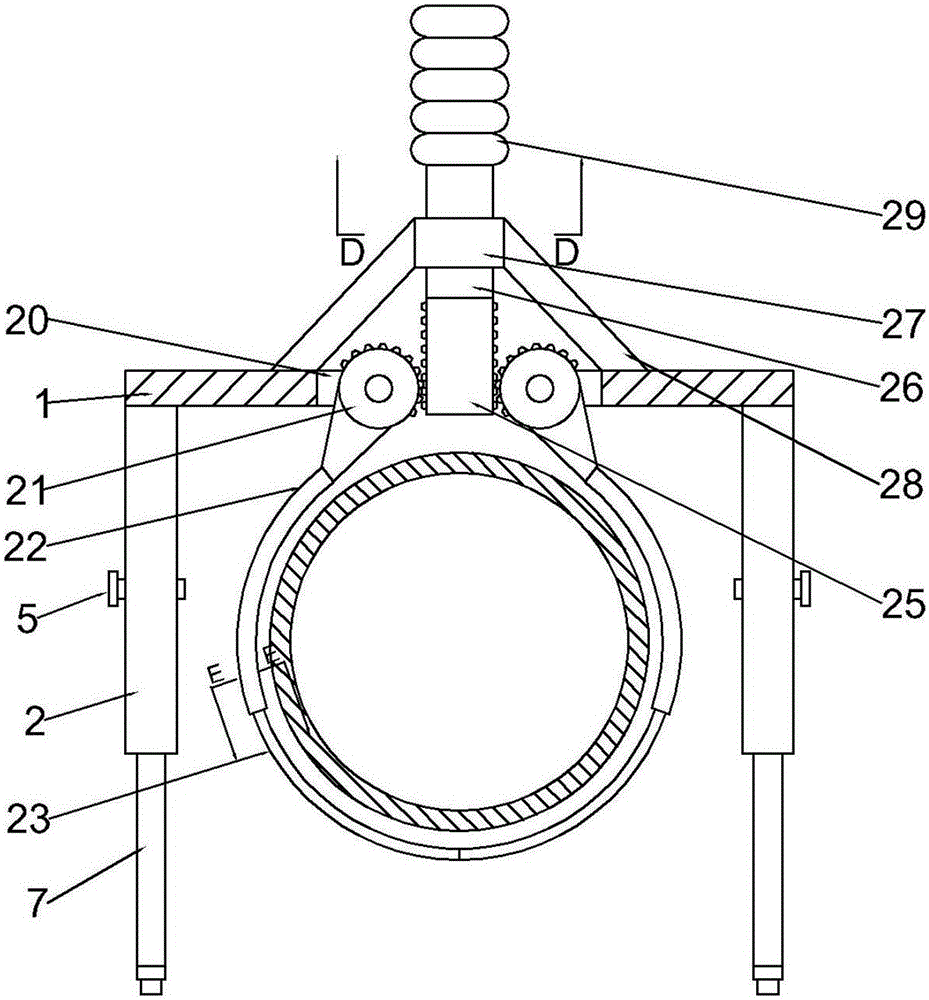

[0025] see Figure 1-7 , an anti-corrosion paint spraying maintenance device suitable for various specifications of oil pipelines, comprising a mounting plate 1, a pair of sleeves 2 are fixedly connected to the left side of the lower part of the mounting plate 1, and the inside of the sleeve 2 is provided with a leg column 7 , the top of the leg column 7 is connected to the inside of the sleeve 2 through a No. 1 coil spring 6, the side wall of the sleeve 2 is provided with a number of No. 1 fixing pin holes 3, and the upper part of the outrigger column 7 is provided with a No. 2 Fixed pin holes 4, the No. 1 fixed pin hole 3 and the No. 2 fixed pin hole 4 pass through expansion pins 5, and the bottom right side of the mounting plate 1 is fixedly connected with a pair of telescopic rods 9, outrigger columns 7 and telescopic The bottom ends of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com