A method of using a dedicated activated prilling tower for the preparation of a volatile organic compound waste gas active adsorbent

A technology of organic compounds and active adsorbents, which is applied in the field of special activated prilling towers for the preparation of active adsorbents for volatile organic compounds waste gas, can solve the problems of high labor intensity of operators, different process devices, occupational disease hazards, etc., and is conducive to safety. The effect of production, yield improvement, and burden reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

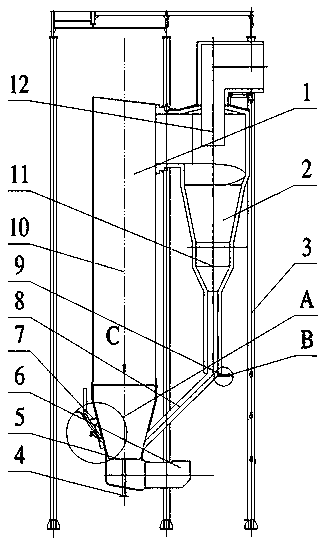

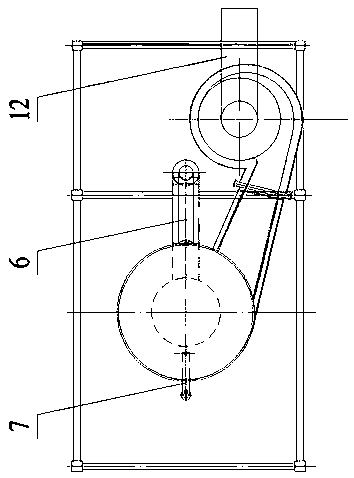

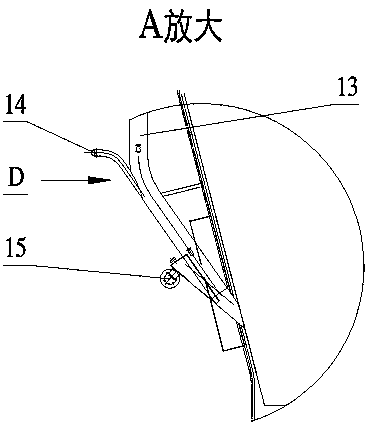

[0026] The device will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] The invention is attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a method for using a dedicated activated prilling tower for the preparation of volatile organic compound exhaust gas active adsorbents is characterized in that: step 1, first use the waste heat of a circulating fluidized bed at 30-35°C and an oxygen content of 5-9% Exhaust gas from the boiler purges the activated prilling tower assembly 1 and the feeder 2 on the support frame 3 for 30 to 60 minutes to reduce the temperature of the activated prilling tower assembly 1 and the feeder 2 to 30 to 35°C. Prevents superheated sulfur explosion and provides cool ambient temperature.

[0028] Step 2, formula components circulating fluidized bed coal-fired boiler fly ash, superheated sulfur steam, disulfur dichloride respectively from circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com