A kind of overturning aquaculture sewage sand filter tank

A technology for aquaculture sewage and sand filter tanks, which is applied in water/sewage treatment, multi-stage water/sewage treatment, heating water/sewage treatment, etc., and can solve the problem of the corrosion resistance of the inner wall of the sand filter and the wear or corrosion of the inner wall of the sand filter , lack of pre-filtration sterilization device and other issues, to achieve the effect of improving the safety of filtration, convenient cleaning and filtering, and preventing hand slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

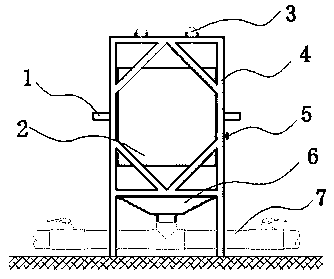

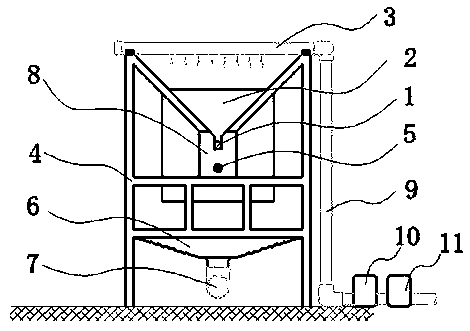

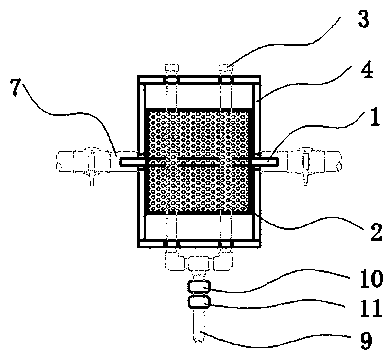

[0028] Such as Figure 1~6 As shown, a flip-type cultivation sewage sand filter tank includes an outer truss 4, a filter tank 2, a sump 6, and a drainage pipe 7. The outer truss 4 is connected with a rain pipe 3, and the filter tank 2 is placed in the outer truss 4. The filter tank 2 is provided with a turning shaft 1, the shower pipe 3 is arranged above the filter tank 2, and a sump 6 is provided below the filter tank 2, and the sump 6 is connected to the drain pipe 7, and the inner wall of the filter tank 2 is provided with an anti-corrosion wear-resistant coating. Floor;

[0029] The front of the outer truss 4 is a square structure, and the side is a diamond structure, which ensures the turning space of the filter tank 2 and the overall stability of the device, and improves the safety of filtration.

[0030] The drain pipe 7 is a two-way drain pipe, and the both sides of the drain pipe 7 are respectively provided with valves, which can be used as the control and selection ...

Embodiment 2

[0040] Such as Figure 1~6 As shown, a flip-type cultivation sewage sand filter tank includes an outer truss 4, a filter tank 2, a sump 6, and a drainage pipe 7. The outer truss 4 is connected with a rain pipe 3, and the filter tank 2 is placed in the outer truss 4. The filter tank 2 is provided with a turning shaft 1, the shower pipe 3 is arranged above the filter tank 2, and a sump 6 is provided below the filter tank 2, and the sump 6 is connected to the drain pipe 7, and the inner wall of the filter tank 2 is provided with an anti-corrosion wear-resistant coating. Floor;

[0041] The front of the outer truss 4 is a square structure, and the side is a diamond structure, which ensures the turning space of the filter tank 2 and the overall stability of the device, and improves the safety of filtration.

[0042] The drain pipe 7 is a two-way drain pipe, and the both sides of the drain pipe 7 are respectively provided with valves, which can be used as the control and selection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com