Preparation method of handmade ice cream powder

An ice cream powder, hand-beating technology, applied in frozen desserts, cocoa, food science, etc., to achieve the effects of high expansion rate, short freezing time, and short use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

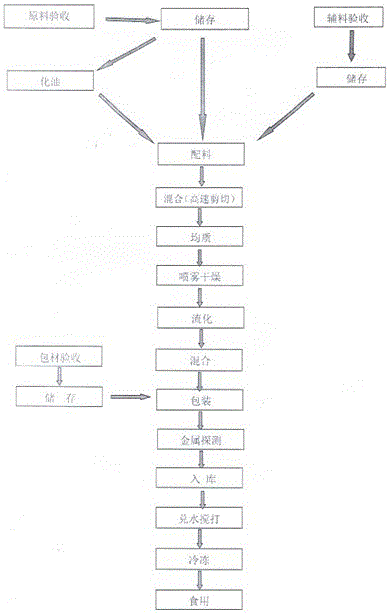

Method used

Image

Examples

Embodiment 1

[0023] (1) Put the vegetable oil into the oil pot, open the steam valve to heat it to melt, close the valve when the temperature reaches 60°C, add monoglyceride fatty acid ester into the oil pot, stir evenly to get the oil phase for later use, among which the vegetable oil Add 250kg, add 10kg monoglyceride fatty acid ester;

[0024] (2) Pour 400kg of dairy products and 50kg of emulsification stabilizer into deionized water together. The emulsification stabilizer includes sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, locust bean gum, stir at high speed until fully dissolved, and then Make it uniform through a colloid mill to become a paste liquid, wherein the weight-number ratio of sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, and locust bean gum is 15-20:15-20:3-5: 2-3:1-1.5;

[0025] (3) Put 200kg of glucose syrup in a mixing tank, add the paste liquid obtained in step (2), stir evenly, add the oil phase obtained in s...

Embodiment 2

[0030] (1) Put the vegetable oil into the oil pot, open the steam valve to heat it to melt, close the valve when the temperature reaches 60°C, add monoglyceride fatty acid ester into the oil pot, stir evenly to get the oil phase for later use, among which the vegetable oil Add 300kg, add 15kg of monoglyceride fatty acid ester;

[0031] (2) Pour 450kg of dairy products and 60kg of emulsion stabilizer into deionized water. The emulsion stabilizer includes sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, and locust bean gum. Stir at high speed until fully dissolved, then Make it uniform through a colloid mill to become a paste liquid, wherein the weight-number ratio of sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, and locust bean gum is 15-20:15-20:3-5: 2-3:1-1.5;

[0032] (3) Put 260kg of glucose syrup in a mixing tank, add the paste liquid obtained in step (2), stir evenly, add the oil phase obtained in step (1), stir even...

Embodiment 3

[0037] (1) Put the cream into the melting oil pot, open the steam valve to heat it to melt, close the valve when the temperature reaches 60°C, add monoglyceride fatty acid ester into the melting oil pot, stir well to get the oil phase for later use, among which the cream Add 280kg, add 16kg monoglyceride fatty acid ester;

[0038] (2) Pour 460kg of dairy products and 70kg of emulsion stabilizer into deionized water. The emulsion stabilizer includes sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, and locust bean gum. Stir at high speed until fully dissolved, then Make it uniform through a colloid mill to become a paste liquid, wherein the weight-number ratio of sodium caseinate, dipotassium hydrogen phosphate, carrageenan, konjac gum, and locust bean gum is 15-20:15-20:3-5: 2-3:1-1.5;

[0039] (3) Put 240kg of glucose syrup in a mixing tank, add the paste liquid obtained in step (2), stir evenly, add the oil phase obtained in step (1), stir again, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com