Low-lactose acid goat milk and preparation method thereof

A technology of lactobionic goat and lactobionic acid, applied in the field of low-lactose yogurt and its preparation, can solve the problems of reduced number of live bacteria, lactose intolerance, unstable number of live lactic acid bacteria, etc., achieve fine tissue and improve immunity force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 A kind of low-lactose yogurt

[0024] The low-lactose yogurt includes the following raw materials in parts by weight:

[0025] 700 parts of raw goat milk, 5 parts of seabuckthorn juice, 6 parts of cypress seed extract, 4 parts of lily extract, 4 parts of aloe polysaccharide, 2 parts of starch, 15 parts of sucrose, 4 parts of fructose syrup, 0.1 part of Lactobacillus salivarius, 0.2 part of Lactobacillus casei, 0.3 part of Leuconostoc enterococci.

[0026] The bacteria concentration of the Lactobacillus salivarius is 1.2×10 7 cfu / g; said Lactobacillus paracasei, the bacterial concentration is 1.5×10 7 cfu / g; the Leuconostoc enterococcus, the bacterial concentration is 1.6×10 7 cfu / g.

[0027] The Lactobacillus salivarius, Lactobacillus paracasei, and Leuconostoc enterococcus are purchased from the market.

[0028] The preparation method of the low-lactose yogurt comprises the following steps:

[0029] (1) Weigh raw materials

[0030] According to the ...

Embodiment 2

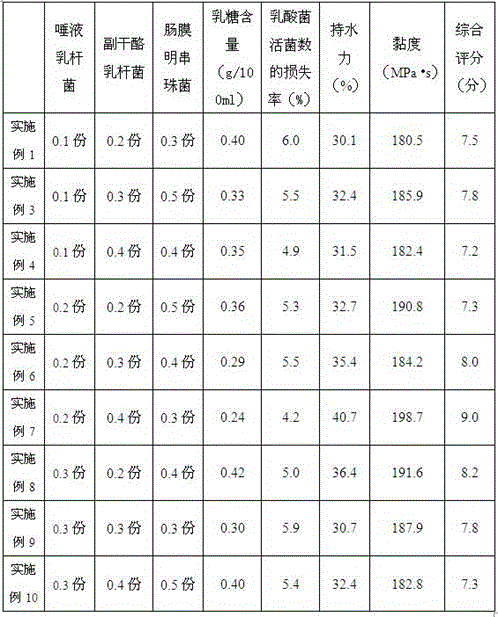

[0054] Embodiment 2 The proportioning optimization experiment of leavening agent

[0055] On the basis of Example 1, only the addition amount of three kinds of fermented bacteria was changed to prepare yogurt. The evaluation indicators of yogurt include lactose content, loss rate of viable lactic acid bacteria on the 25th day of refrigeration, water holding capacity, and viscosity. , comprehensive score and other indicators.

[0056] Table 1 Optimizing Experiment of Fermentation Ratio

[0057]

[0058] Through the above-mentioned preferred experiments, it can be seen that Example 7 is a preferred embodiment, that is, the addition amounts of Lactobacillus salivarius, Lactobacillus paracasei, and Leuconostoc enterococcus are respectively 0.2 parts, 0.4 parts, and 0.3 parts.

[0059] The yogurt prepared in Example 7 of the present invention has fine and uniform tissue, no whey precipitation, a protein content of 3.1%, a fat content of 3.0%, non-fat milk solids ≥ 8.3%, an acidit...

Embodiment 11

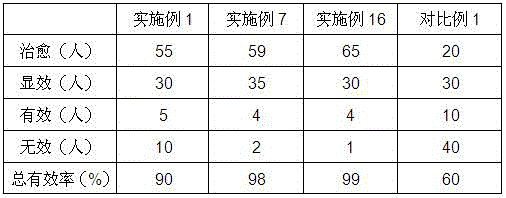

[0060] Example 11 Optimum fermentation conditions

[0061] On the basis of Example 7, only changing the fermentation step, the time of the first stage of fermentation, the heating rate of the second stage, and the fermentation temperature of the third stage, the evaluation indicators of the prepared yogurt include lactose content, refrigerated 25 The daily loss rate of viable lactic acid bacteria, water holding capacity, viscosity, comprehensive score and other indicators.

[0062] Table 2 fermentation condition optimization experiment

[0063]

[0064] Through the above optimization, it can be seen that Example 16 is a preferred experiment, that is, in the fermentation step, the time of the first stage of fermentation is preferably 2 hours, the temperature rise rate of the second stage is preferably 1.5°C / min, and the fermentation temperature of the third stage is preferably is 42°C.

[0065] The yogurt prepared in Example 16 of the present invention has fine and uniform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com