Method for producing carboxymethyl cellulose salt for electrodes of nonaqueous electrolyte secondary batteries, electrode for nonaqueous electrolyte secondary batteries, and nonaqueous electrolyte secondary battery

一种非水系电解液、羧甲基纤维素的技术,应用在非水电解质蓄电池电极、非水电解质蓄电池、电池电极等方向,能够解决剥落等问题,达到防止条纹或针孔、优异粘着强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

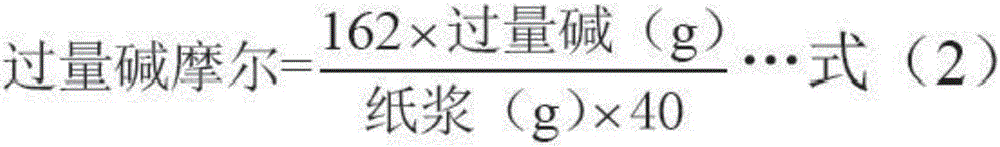

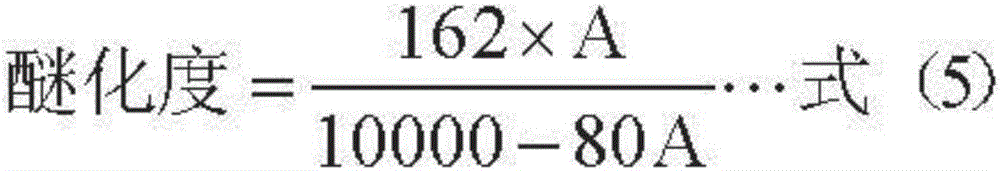

[0127] An alkaline solution was prepared by dissolving 110 g of sodium hydroxide in 1000 g of a solvent adjusted to a mixing ratio of isopropanol and water to 80:20 (mass ratio). This alkaline solution was put into a 5-liter twin-shaft kneader reactor, and 200 g of sheet-shaped raw material cellulose (lint pulp: HVE manufactured by US-based Bokai Technology Co., Ltd.) was added for about 5 minutes while stirring. The alkali cellulose formation reaction was implemented by stirring at 25 degreeC for 50 minutes.

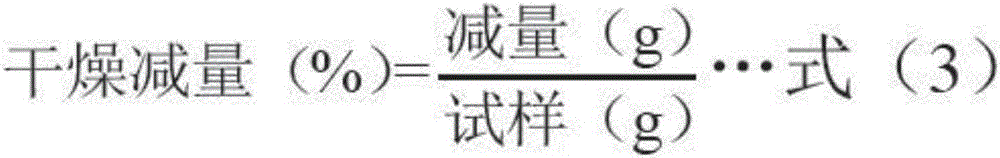

[0128] After the above reaction, the reaction mixture was cooled to 30°C, and the monochloroacetic acid solution was adjusted to 25°C. The monochloroacetic acid solution was dissolved in 110 g of monochloroacetic acid in the reaction medium (a mixture of 80 g of isopropanol and 20 g of water) formed, and then it took 10 minutes to add the monochloroacetic acid solution to the alkali cellulose in the reactor. Thereafter, the temperature was gradually raised to 78° C. ov...

Embodiment 2

[0135] The pH after recovery of the reaction solvent was 8.5, and the heating time was 90 minutes, and it manufactured similarly to Example 1, and obtained carboxymethylcellulose sodium salt.

Embodiment 3

[0137] The amount of the mixed solvent of the isopropanol and water of the alkali cellulose reaction is changed to 1400g, the amount of sodium hydroxide is changed to 105g, and the pH value after the recovery of the reaction solvent is changed to 8.4, except that, using the same method as in Example 1 Manufactured in a manner to obtain carboxymethylcellulose sodium salt.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com