A kind of micro-filled concentrator based on metal substrate and preparation method thereof

A metal substrate and filling technology, which is applied in the field of structure and preparation of metal substrate micro-filling concentrators, can solve problems such as mismatching concentrators, achieve improved detection limits, various micro-processing methods, and enhanced effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation on the invention.

[0039] The metal substrate of the micro-packed enricher of the present invention is brass H96 as an example, but it is not limited to H96, and can also be other metal or alloy materials with good performance; the enrichment object is ethylene gas as an example, and the choice of adsorbent material Carbosieve SII.

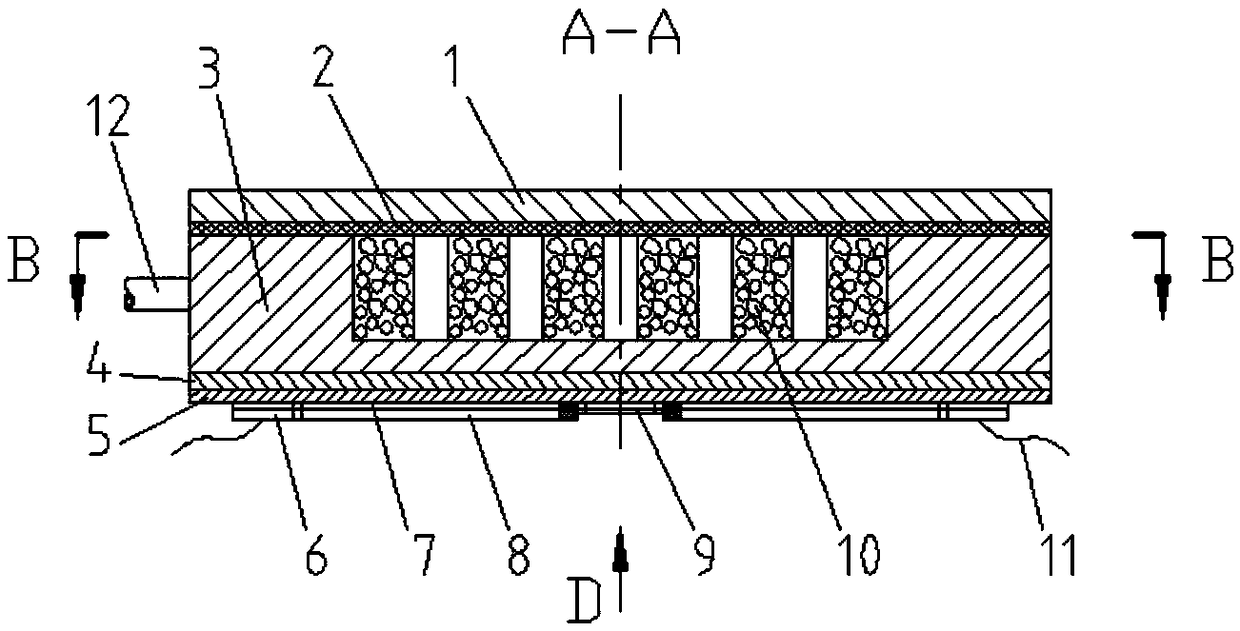

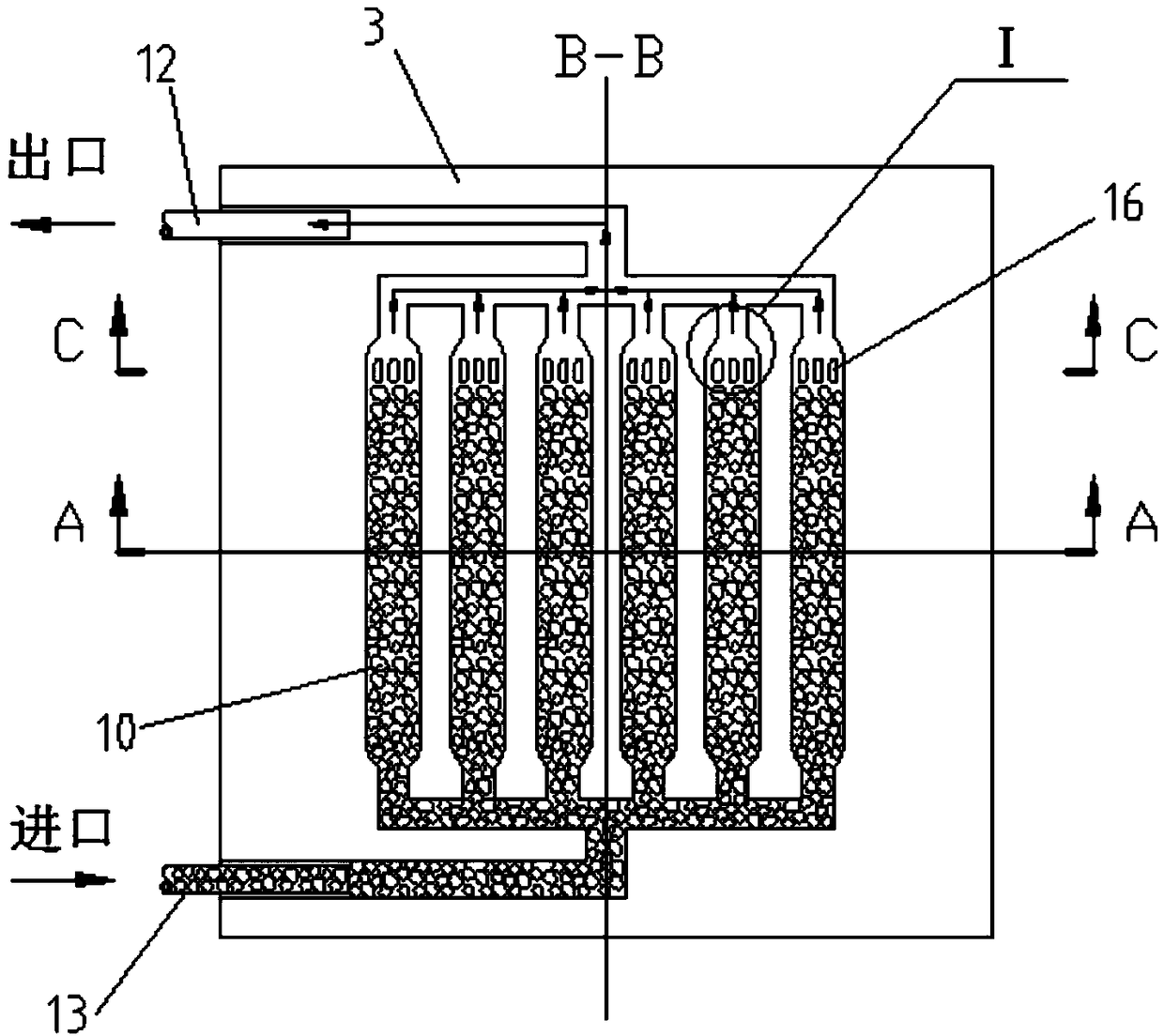

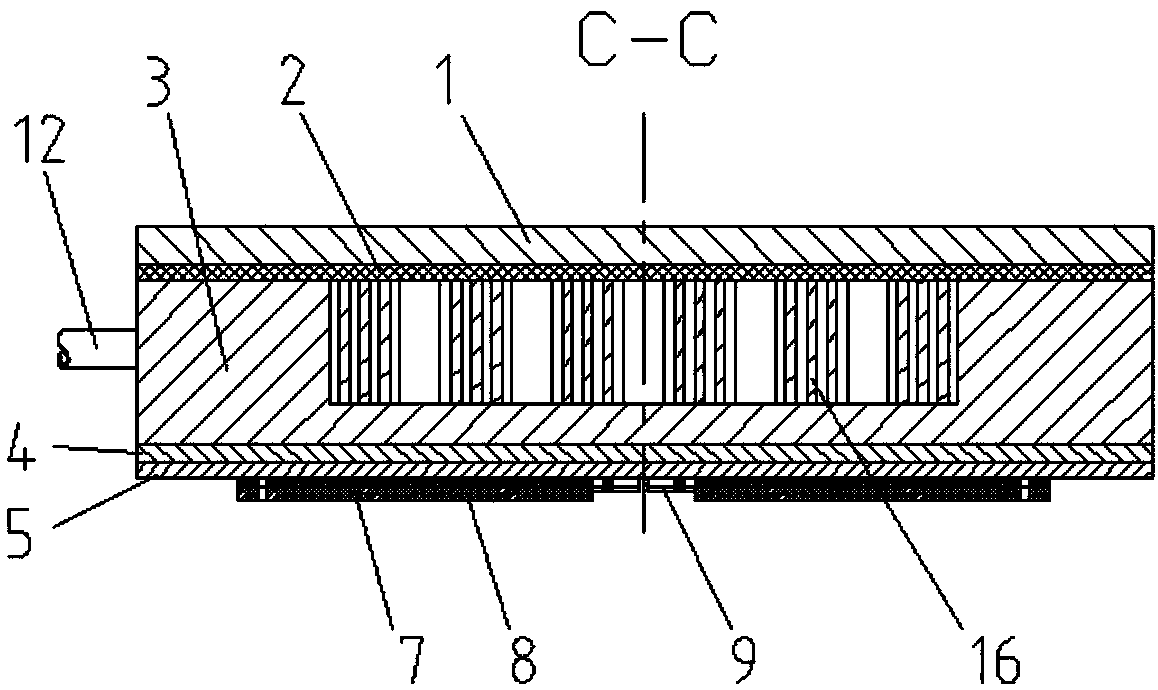

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of micro-filling concentrator based on metal substrate, comprises the polished encapsulation sheet 1 that distributes sequentially from top to bottom, the brazing layer (tin-lead solder) 2 of deposition, substrate layer 3, magnetic SiO deposited by controlled sputtering 2 Dielectric layer 4 and low pressure chemical vapor deposited Si 3 N 4 Dielectric layer 5, wherein, encapsulation sheet 1 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com