Novel modified polyvinyl chloride pipe fitting and preparation method thereof

A technology for polyvinyl chloride and pipe fittings is applied in the field of new modified polyvinyl chloride pipe fittings and their preparation, which can solve problems such as pipe fitting deformation, and achieve the effects of good weather resistance, high Vicat softening point and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

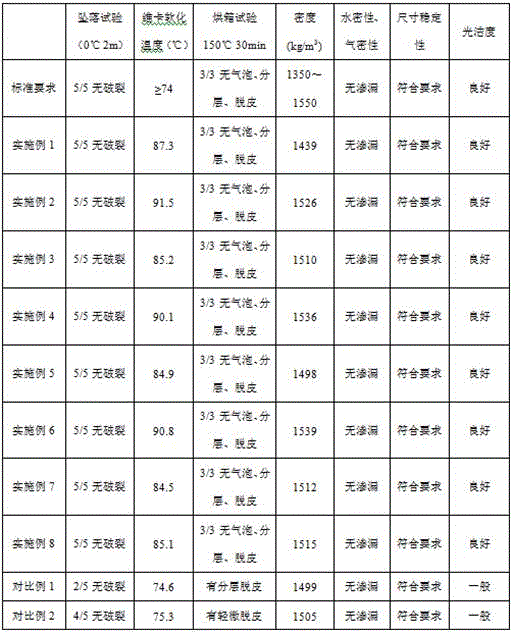

Examples

Embodiment 1

[0042] The pipe fitting formulation is made of the following components in parts by weight:

[0043] PVC resin (SG-8) 100 parts, heat stabilizer (calcium zinc stabilizer) 5.5 parts, processing modification aid (ACR) 2.0 parts, silicate-like modifier (ultrafine fibrous wollastonite powder) 20 parts parts, heat-resistant modifier (α-methylstyrene-based polymer) 5 parts, lubricant (polyethylene wax) 1.5 parts, lubricant (polyethylene oxide) 0.2 parts, lubricant (calcium stearate) 0.5 parts parts, 0.2 parts of antioxidant, 2.5 parts of pigment (titanium dioxide).

Embodiment 2

[0045] The pipe fitting formulation is made of the following components in parts by weight:

[0046] PVC resin (SG-7) 100 parts, heat stabilizer (calcium zinc stabilizer) 6.5 parts, processing modification aid (ACR) 3.0 parts, silicate-like modifier (ultra-fine fibrous wollastonite powder) 30 parts parts, heat-resistant modifier (α-methylstyrene-based polymer or) 10 parts, lubricant (polyethylene wax) 2.0 parts, lubricant (polyethylene oxide) 0.2 parts, lubricant (calcium stearate) 1.0 parts, 0.2 parts of antioxidant, 2.5 parts of pigment (titanium dioxide).

Embodiment 3

[0048] The pipe fitting formulation is made of the following components in parts by weight:

[0049] PVC resin (SG-8) 100 parts, heat stabilizer (calcium zinc stabilizer) 6 parts, processing modification aid (ACR) 0.5 parts, silicate-like modifier (ultra-fine fibrous wollastonite powder) 10 parts parts, heat-resistant modifier (α-methylstyrene-based polymer) 5 parts, lubricant (polyethylene wax) 1.5 parts, lubricant (polyethylene oxide) 0.2 parts, lubricant (calcium stearate) 0.5 parts part, 0.2 part of antioxidant, 0.01 part of pigment (titanium dioxide).

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com