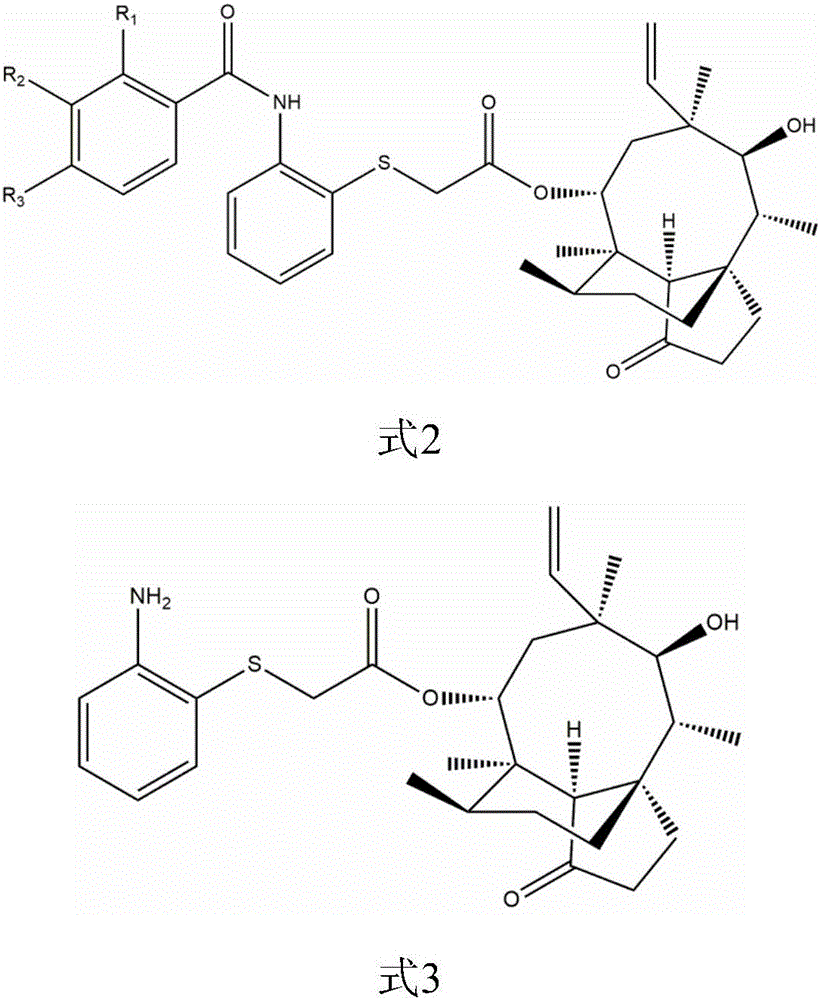

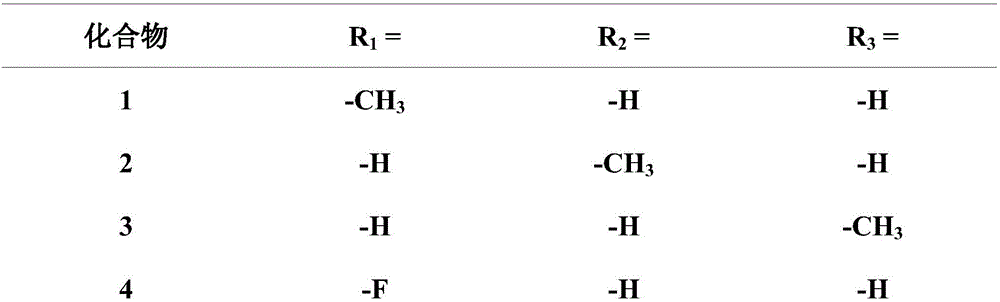

Pleuromutilin derivative with 2-amino phenyl mercaptan side chain and preparing method and application of pleuromutilin derivative

A technology of pleuromutilin and aminophenylthiol, which is applied in thioether preparation, sulfonate preparation, organic chemistry, etc., can solve the problem of rare drug-resistant bacteria, and achieve the effect of good in vitro antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Example 1: Synthesis of 22-O-[2-(2-methylbenzamide)phenyl]thioacetyl Murelin (Compound 1)

[0062] Intermediate II 0.82g (1.88mmol) was dissolved in 35ml ethyl acetate, 2-methylbenzoic acid (2.07mmol) and oxalyl chloride 2.07mmol were added, heated and stirred at about 70°C for 1 hour to obtain the target product. The resulting mixed solution was evaporated to dryness by rotating to make the mixture redissolved in dichloromethane. Add 1g of 100-200 mesh silica gel and mix thoroughly. After the solvent evaporates, the above crude product-silica powder mixture is purified by column chromatography (200~300 The mesh silica gel powder is the stationary phase, and petroleum ether: ethyl acetate=1:1 is the mobile phase) to obtain the product 22-O-[2-(2-methylbenzamide)phenyl]thioacetyl murine ( The pure product of compound 1). The yield was 86.55%. HR-MS(ESI): Cal: 604.3091; Found: 604.3117.

Embodiment 2

[0063] Example 2: Synthesis of 22-O-[2-(3-methylbenzamido)phenyl]thioacetylmurine (Compound 2)

[0064] Intermediate II 0.82g (1.88mmol) was dissolved in 35ml of dichloromethane, 3-methylbenzoic acid (2.07mmol) and tert-butyl chloroformate 2.07mmol were added, heated and stirred at about 70°C for 1 hour to obtain the target product. The resulting mixed solution was evaporated to dryness by rotating to make the mixture redissolved in dichloromethane. Add 1g of 100-200 mesh silica gel and mix thoroughly. After the solvent evaporates, the above crude product-silica powder mixture is purified by column chromatography (200~300 The mesh silica gel powder is the stationary phase, and petroleum ether: ethyl acetate=1:1 is the mobile phase) to obtain the product 22-O-[2-(3-methylbenzamide)phenyl]thioacetyl Murelin ( Compound 2) pure product. The yield was 85.75%. HR-MS(ESI): Cal: 604.3091; Found: 604.3110.

Embodiment 3

[0065] Example 3: Synthesis of 22-O-[2-(4-methylbenzamido)phenyl]thioacetylmurine (Compound 3)

[0066] 0.82g (1.88mmol) of Intermediate II was dissolved in 35ml of dichloromethane, 4-methylbenzoic acid (2.07mmol) and 2.07mmol of thionyl chloride were added, heated and stirred at about 70°C for 1 hour to obtain the target product. The resulting mixed solution was evaporated to dryness by rotating to make the mixture redissolved in dichloromethane. Add 1g of 100-200 mesh silica gel and mix thoroughly. After the solvent evaporates, the above crude product-silica powder mixture is purified by column chromatography (200~300 The mesh silica gel powder is the stationary phase, and petroleum ether: ethyl acetate=1:1 is the mobile phase) to obtain the product 22-O-[2-(4-methylbenzamide)ethyl]thioacetyl murine ( Compound 3) pure product. The yield was 83.09%. HR-MS(ESI): Cal: 604.3091; Found: 604.3110.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com