Ceramic fiber reinforcing and toughening type diatom mud material and preparation method thereof

A ceramic fiber, reinforced and toughened technology, which is applied in the field of ceramic fiber reinforced and toughened diatom mud material and its preparation, can solve the problems that cannot be used alone, the variety of wood fiber is single, and the reinforcing effect is not enough, so as to improve the adhesion Strength, health protection, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

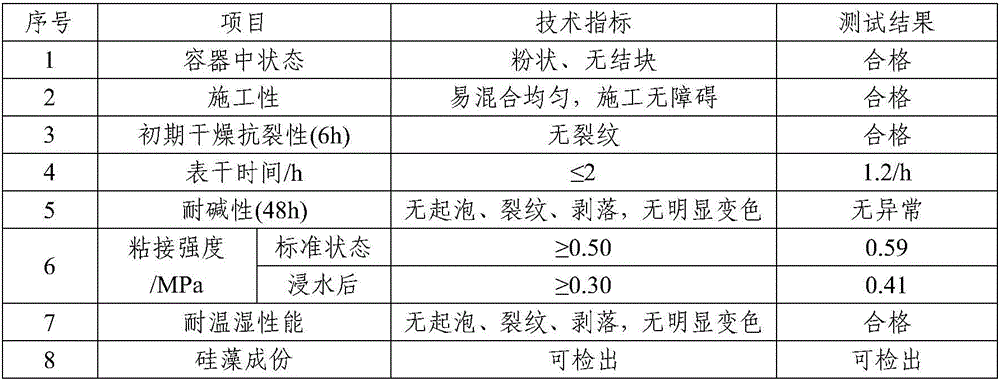

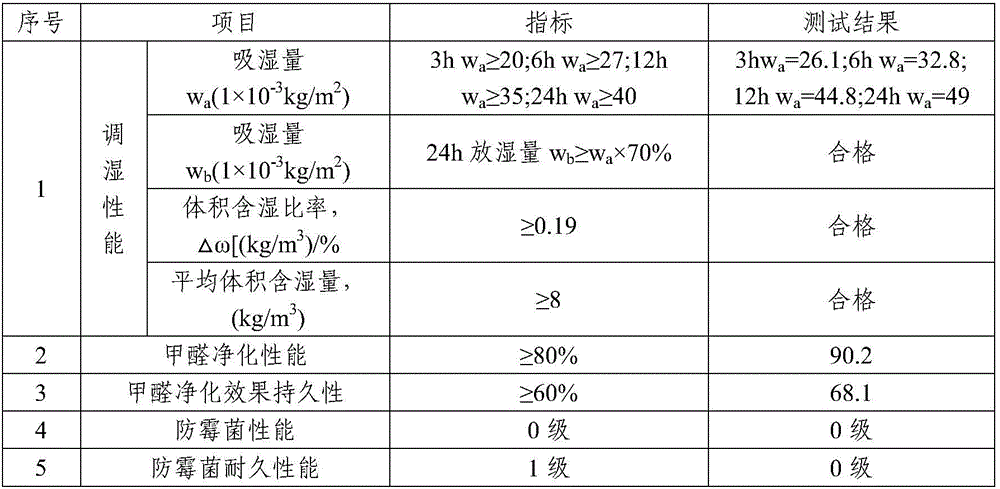

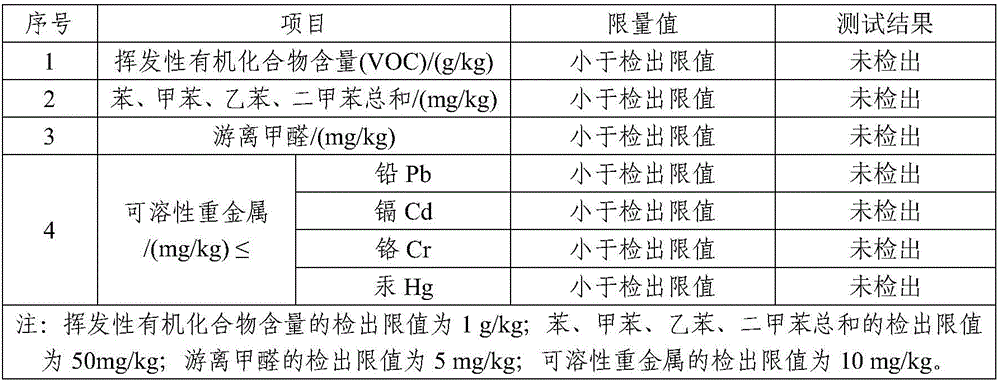

Examples

Embodiment 1

[0025] 28 parts of diatomite with a silicon content of 95%, 30 parts of heavy calcium carbonate with a particle size of 23 μm, 18 parts of ash calcium powder with a particle size of 60 μm, 16 parts of quartz sand with a particle size of 700 μm, and 3 parts of negative ions with a particle size of 8 μm Powder, 0.5 parts of sodium carboxymethyl starch with a viscosity of 30000, 1 part of sodium carboxymethyl cellulose with a viscosity of 75000 and 0.3 parts of cassava pregelatinized starch with a particle size of 110 μm are fully and uniformly prepared mixed powder; 3 parts of rutile nano-titanium dioxide powder in deionized water are ultrasonically homogenized and added to the water to prepare a nano-titanium dioxide mixed solution; the mixed powder is added to the nano-titanium dioxide mixed solution, and after stirring evenly, add 0.3 parts with a diameter of 3 μm and a length of The 80mm 1000-type ceramic fiber continues to stir until it is uniform, and the ceramic fiber-rein...

Embodiment 2

[0027] 20 parts of diatomite with a silicon content of 90%, 40 parts of heavy calcium carbonate with a particle size of 100 μm, 8 parts of ash calcium powder with a particle size of 80 μm, 18 parts of quartz sand with a particle size of 830 μm, and 4 parts of calcium carbonate with a particle size of 5.5 μm Negative ion powder, 0.5 parts of hydroxypropyl methylcellulose with a viscosity of 20000 and 0.3 parts of corn starch with a particle size of 160 μm are fully and uniformly prepared mixed powder; 4 parts of rutile nano-titanium dioxide powder dispersed in deionized water are ultrasonically After it is uniform, it is added into water to prepare a nano-titanium dioxide mixed solution; the mixed powder is added to the nano-titanium dioxide mixed solution, and after being stirred evenly, 1.5 parts of 1600 ceramic fibers with a diameter of 12 μm and a length of 250 mm are added and stirred until uniform, and the obtained Ceramic fiber reinforced and toughened diatom mud material...

Embodiment 3

[0029] 25 parts of diatomite with a silicon content of 92%, 20 parts of heavy calcium carbonate with a particle size of 90 μm, 12 parts of ash calcium powder with a particle size of 23 μm, 8 parts of quartz sand with a particle size of 600 μm, and 2 parts of calcium carbonate with a particle size of 3.3 μm Anion powder, 0.6 parts of sodium carboxymethyl starch with a viscosity of 100000, 0.6 part of sodium carboxymethylcellulose with a viscosity of 140000, 0.6 part of hydroxypropyl methylcellulose with a viscosity of 50000 and 0.1 part of cassava with a particle size of 90 μm The gelatinized starch is fully and uniformly prepared into a mixed powder; 5 parts of anatase nano-titanium dioxide powder dispersed in deionized water are ultrasonically uniform and then added to the water to prepare a nano-titanium dioxide mixed liquid; the mixed powder is added to the nano-titanium dioxide mixed In the solution, after stirring evenly, add 1 part of 1400-type ceramic fiber with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com