A 3D printing method based on mesh model simplification

A 3D printing and grid model technology, applied in 3D modeling, image data processing, manufacturing auxiliary devices, etc., can solve problems such as the limitation of structural optimization results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

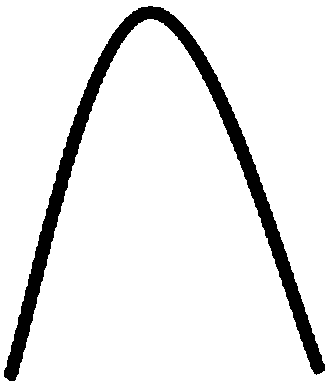

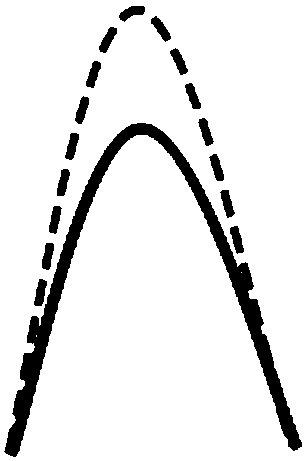

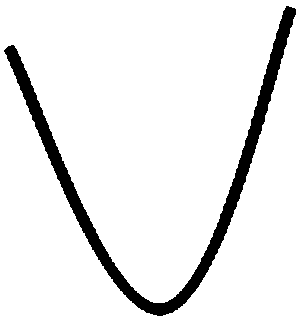

[0072] In the simplified error based on the quadratic error metric algorithm, the order of edge folding and the position of new points are determined by the quadratic error measure, so before calculating the folding cost of the next round of folding, by calculating the curvature value of each folded vertex, Combining with polyhedron vertex convexity judgment method to determine the convexity of folded vertices, the quadratic error measurement algorithm is improved to judge whether vertices should be folded. Such as Figure 1a ~ Figure 1d as shown, Figure 1a Indicates that the folded vertices are convex, Figure 1b Indicates that the curvature increases. If the folded vertex is a convex point, and the curvature increases before and after simplification, the vertex will not be folded; Figure 1c Indicates that the folded vertices are concave, Figure 1d Indicates that the curvature decreases. If it is a concave point and the curvature decreases before and after simplification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com