Method of improving rare earth grade of hybrid rare earth ores

A mixed rare earth and grade technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of restricting rare earth beneficiation, smelting development, restricting the development of rare earth beneficiation, and the decline of rare earth recovery rate, so as to ensure the rare earth High recovery rate, wide application range, and high recovery rate of rare earths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

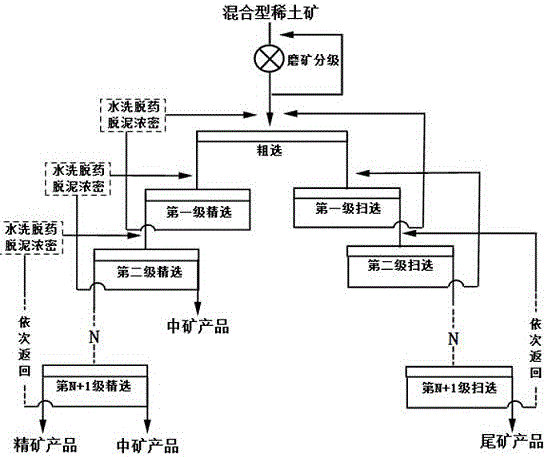

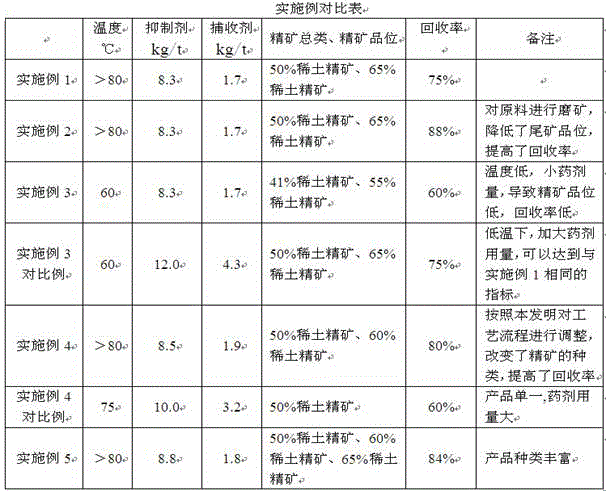

[0024] Using Baotou Iron and Steel Oxidized Iron Dressing Tailings as raw material, rare earth REO grade is 7.5%, particle size is -200 mesh, accounting for 85%, using the process technology of the present invention, the particle size of raw materials meets the requirements of this technology, and directly adopts primary roughing, The beneficiation process combined the closed-circuit cycle and open-circuit process of secondary sweeping, three-time beneficiation, and flotation operation of rare earth on this raw material. The inhibitor used is water glass, and the collector used is Linfeng 8# agent , the foaming agent used is 2# oil.

[0025] 1) Rough separation: add water to mix the raw materials and add them to the flotation tank, and start stirring. The mass concentration of the rough separation pulp is 55%, and the temperature of the pulp is greater than 80°C; while stirring, add in sequence according to the weight ratio: inhibit Agent 3.5kg / t, collector 0.8kg / t, foaming ag...

Embodiment 2

[0033] Still using the Baotou Iron and Steel oxidation ore iron dressing tailings in Example 1 as raw material, the rare earth REO grade is 7.5%, and the particle size is -200 mesh accounting for 85%. Utilize the process technology of the present invention to carry out flotation recovery of rare earth, in order to improve the recovery of rare earth Firstly, the raw material is ground to -200 mesh, accounting for more than 95%, and then the raw material is flotation rare earth by using a beneficiation process that combines a closed-circuit cycle and an open-circuit process of primary roughing, secondary sweeping, and three-time beneficiation. In the operation, the inhibitor used is water glass, the collector used is Linfeng 8# medicament, and the foaming agent used is 2# oil.

[0034] 1) Rough separation: add water to mix the raw materials and add them to the flotation tank, and start stirring. The mass concentration of the rough separation pulp is 55%, and the temperature of th...

Embodiment 3

[0042] Still Baotou Iron and Steel oxide ore iron dressing tailings in Example 1 is the raw material, the rare earth REO grade is 7.5%, and the particle size is -200 mesh, accounting for 85%. Utilizing the process technology of the present invention to carry out flotation recovery of rare earth, the particle size of the raw material meets this requirement. According to technical requirements, the rare earth flotation operation is carried out on the raw material by directly adopting the beneficiation process combined with the closed-circuit circulation and the open-circuit process of primary roughing, secondary sweeping, and three-time beneficiation. The inhibitor used is water glass. The collector used is Linfeng 8# agent, and the foaming agent used is 2# oil.

[0043] 1) Rough separation: mix the raw materials with water and add them to the flotation tank, and start stirring. The mass concentration of the rough separation pulp is 55%, and the temperature of the pulp is 60°C; w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com