Intensive type curing barn capable of realizing afterheat recycling and zero pollutant emission

A waste heat recovery and intensive technology, which is applied in the field of intensive curing barns, can solve the problems of affecting the quality of tobacco leaf curing, large temperature fluctuations in the tobacco loading room, and low combustion efficiency, so as to reduce the loss of moisture exhaust heat, improve the quality of flue-cured tobacco, and reduce the The effect of total energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

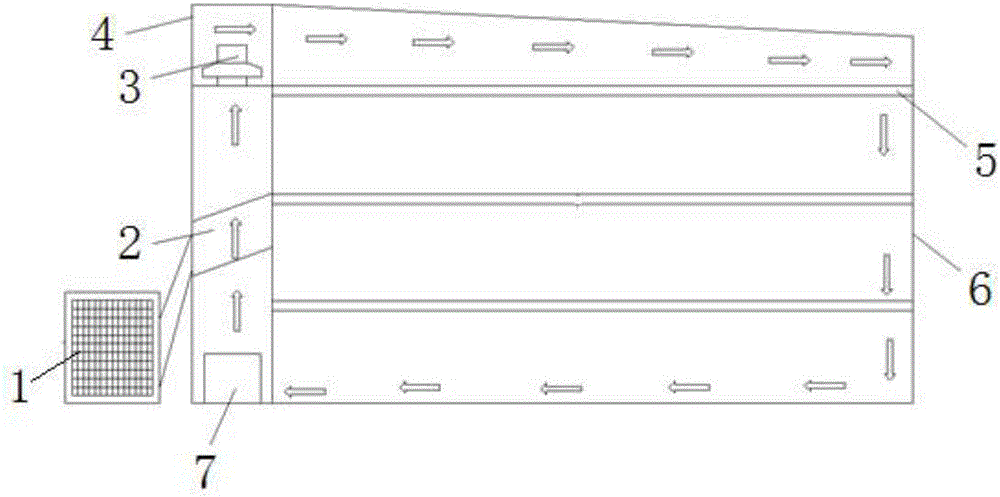

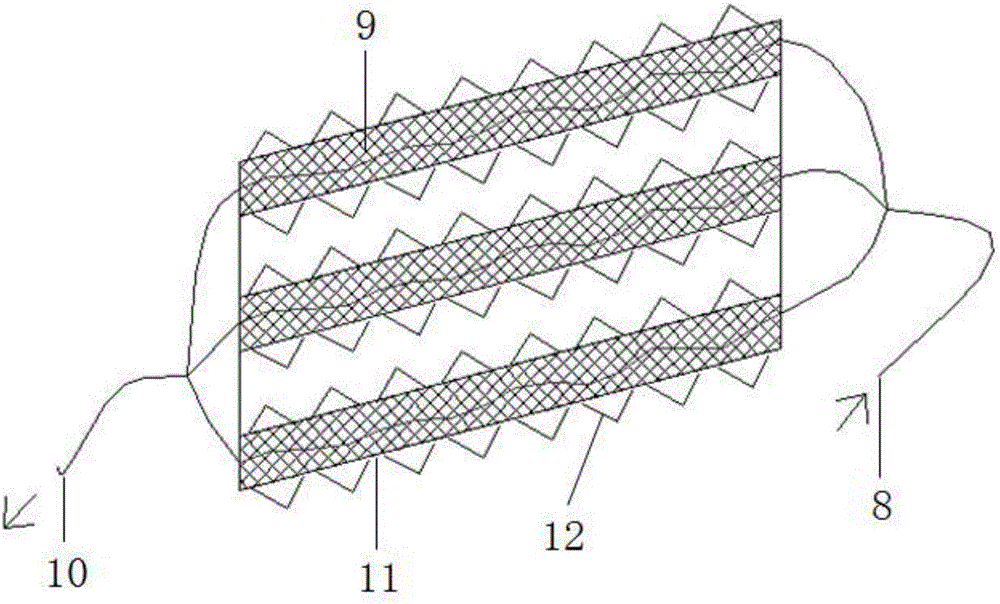

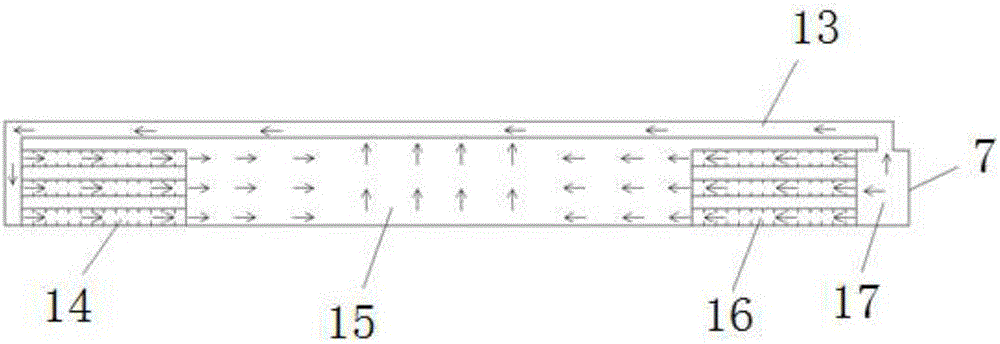

[0024] like figure 1 As shown, an intensive barn with waste heat recovery and zero pollution emission includes a room body, an air source heat pump, a waste heat recovery device and a circulation fan 3 . The room body includes a heating chamber 4 and a smoke chamber 6, and a three-layer smoke rack 5 is arranged in the smoke chamber 6. The ground below the smoke chamber 6 is provided with a layer of thermal insulation layer, the thickness of the thermal insulation layer is 18-22mm, and the thermal insulation layer is an extruded polystyrene foam board.

[0025] The air source heat pump includes an outdoor host 1, a phase-change heat storage condenser 2 and connecting pipes; the outdoor host 1 includes a compressor, an evaporator and a capillary tube, and the outdoor host 1 is placed on one side of the outer wall of the heating room 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com