Preparation and application of graphene coated spherical cobalt disulfide composite material

A graphene-coated, cobalt disulfide technology, used in secondary batteries, electrochemical generators, electrical components, etc., can solve problems such as no graphene-coated spherical cobalt disulfide composite materials, and achieve excellent cycle performance , The effect of good reproducibility and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

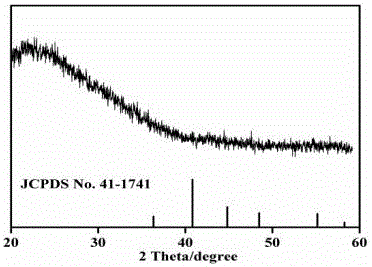

[0020] A kind of preparation of graphene-coated spherical cobalt disulfide composite material, concrete steps are:

[0021] First, dissolve 0.249 g of cobalt acetate tetrahydrate in 10 ml of deionized water. After the cobalt acetate tetrahydrate is completely dissolved, add the resulting solution into 25 ml of graphene oxide solution, stir for 10 minutes, add 0.121 g of L-cysteine, and stir , then add 10ml of ethylene glycol, after stirring, move the final solution into a 40ml reaction kettle, place it in an oven at 160 degrees Celsius, react for 12 hours, wash the resulting product with water several times, and dry it to obtain a graphene package. Composite material coated with spherical cobalt disulfide.

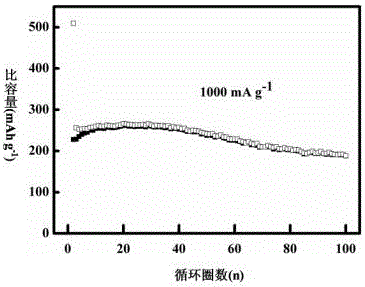

[0022] The described graphene-coated spherical cobalt disulfide composite material is used for sodium-ion batteries, and the specific steps are as follows:

[0023] According to the mass ratio, cobalt disulfide@graphene: polyvinylidene fluoride: acetylene black = 70:20:10...

Embodiment 2

[0027] A kind of preparation of graphene-coated spherical cobalt disulfide composite material, concrete steps are:

[0028] First, dissolve 0.359 g of cobalt acetate tetrahydrate in 10 ml of deionized water. After the cobalt acetate tetrahydrate is completely dissolved, add the resulting solution into 25 ml of graphene oxide solution, stir for 10 minutes, add 0.221 g of L-cysteine, and stir , then add 10ml of ethylene glycol, after stirring, move the final solution into a 40ml reaction kettle, place it in an oven at 160 degrees Celsius, react for 12 hours, wash the resulting product with water several times, and dry it to obtain a graphene package. Composite material coated with spherical cobalt disulfide.

[0029] The described graphene-coated spherical cobalt disulfide composite material is used for sodium-ion batteries, and the specific steps are as follows:

[0030] According to the mass ratio, cobalt disulfide@graphene: polyvinylidene fluoride: acetylene black = 70:20:10...

Embodiment 3

[0034] A kind of preparation of graphene-coated spherical cobalt disulfide composite material, concrete steps are:

[0035] First, dissolve 0.442 g of cobalt acetate tetrahydrate in 10 ml of deionized water. After the cobalt acetate tetrahydrate is completely dissolved, add the resulting solution into 25 ml of graphene oxide solution, stir for 10 minutes, add 0.381 g of L-cysteine, and stir , then add 10ml of ethylene glycol, after stirring, move the final solution into a 40ml reaction kettle, place it in an oven at 180 degrees Celsius, react for 12 hours, wash the resulting product with water several times, and dry it to obtain a graphene package. Composite material coated with spherical cobalt disulfide.

[0036] The described graphene-coated spherical cobalt disulfide composite material is used for sodium-ion batteries, and the specific steps are as follows:

[0037] According to the mass ratio, cobalt disulfide@graphene: polyvinylidene fluoride: acetylene black = 70:20:10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com