L-shaped external gear pump suitable for ultralow-viscosity medium

An ultra-low viscosity, gear pump technology, applied to rotary piston/oscillating piston pump components, pumps, pump components, etc., can solve problems such as increased internal leakage, persistent outlet pressure, and decreased pump volumetric efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

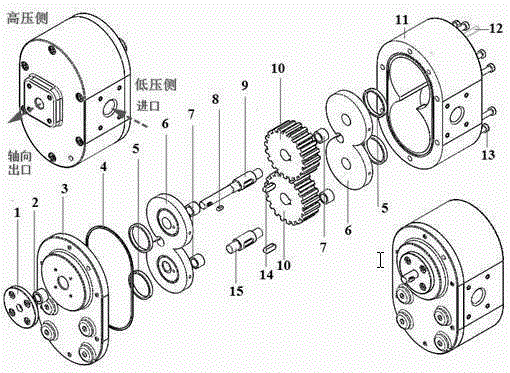

[0017] Example: L-type external gear pump for ultra-low viscosity medium with given volumetric efficiency.

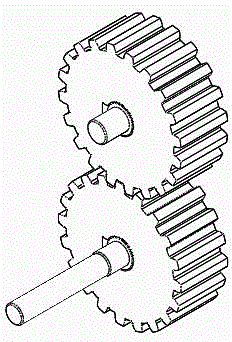

[0018] The present invention includes 1 pressure plate, 2 shaft sealing ring, 3 front cover, 4 pump casing seal, 5 outer sealing ring of floating bushing, 6 pair of floating bushing, 7 self-lubricating sliding bearing, 8 flat key at driving shaft end, 9 driving shaft, 10 a pair of meshing gears, 11 pump casing, 12 positioning pin, 13 fixing screw, 14 shaft-gear flat key, 15 driven shaft.

[0019] According to the existing relevant research theories verified by experiments, the radial leakage in the radial friction pair is obtained q a , the axial leakage in the axial friction pair q z As shown in the following formula.

[0020]

[0021] In the formula, z is the number of teeth; z 0 is the number of teeth in the transition zone; α 0 is the wrap angle of the transition zone; Δ p The differential pressure is the outlet pressure minus the inlet pressure; b is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com