Numerical control type universal polishing unit

A technology of numerical control and polishing mechanism, which is applied to surface polishing machine tools, grinding/polishing equipment, and parts of grinding machine tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

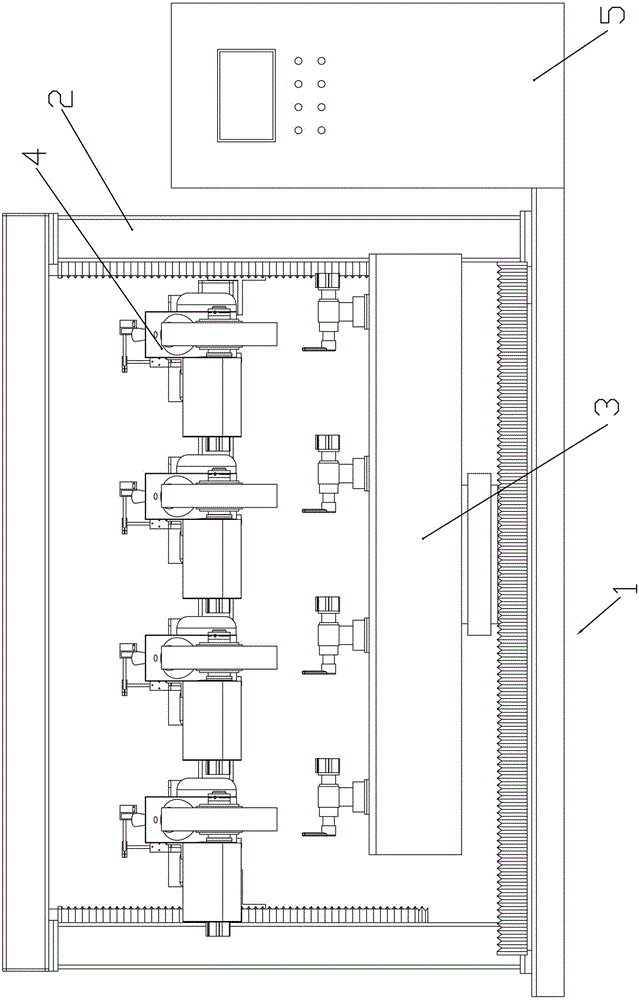

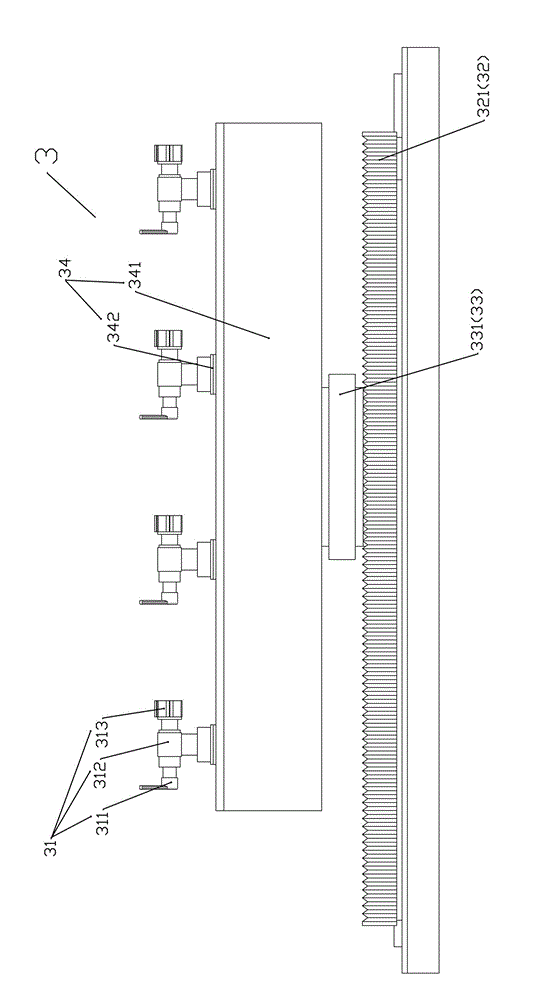

[0032] refer to Figure 1-Figure 3 The CNC type universal polishing unit shown in the figure has a machine base 1, a gantry 2 is fixed on the machine base 1, a product clamping mechanism 3 is installed on the machine base 1, a polishing mechanism 4 is installed on the gantry 2, and a product clamping mechanism is installed 3 cooperate with each other to polish the product, the product clamping mechanism 3 and the polishing mechanism 4 are controlled by the electric control device 5; wherein:

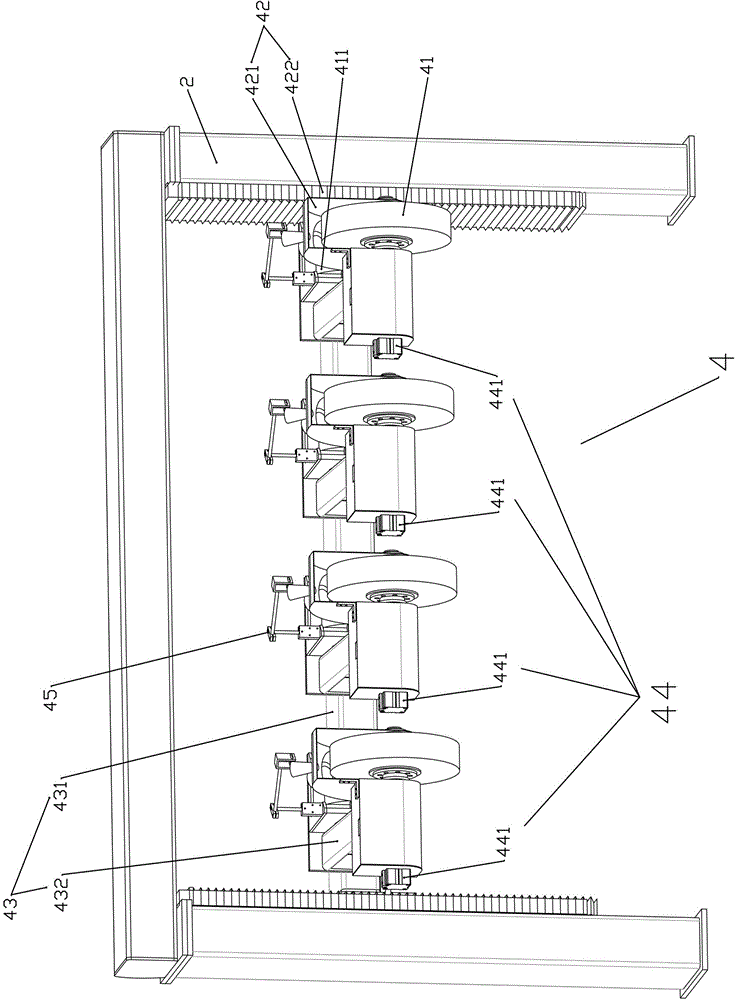

[0033] Polishing mechanism 4 comprises a group of polishing wheels 41 (four in the embodiment), moving assembly 42 up and down, 360 degree rotating assembly 43, polishing wheel swinging assembly 44 and spray gun assembly 45; and the polishing wheel swing assembly 44 cooperate with each other to drive the polishing wheel 41 to move up and down, rotate 360 degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com