Thickness automatically-compensating device for multi-oil-chamber static pressure oil film, and system thereof

A technology of automatic compensation and oil film thickness, which is applied to engine components, engine seals, bearings, etc., and can solve problems such as low production efficiency, difficult processing, and short maintenance cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

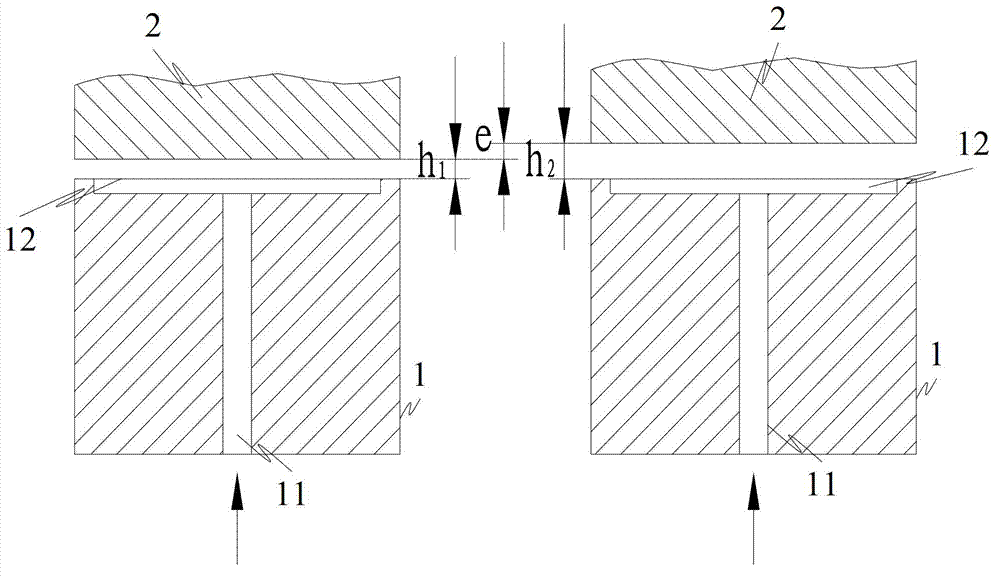

[0012] Such as figure 2 As shown, this embodiment provides a multi-oil chamber hydrostatic oil film thickness automatic compensation device, which is composed of a cylinder 4 and a piston that can move up and down in the cylinder 4 under the action of hydraulic oil without detaching from the cylinder 4 3; where the cylinder 4 is provided with an inner chamber 41 with an open top and a depth greater than or equal to the height of the piston 3, and the piston 3 is arranged in the inner chamber 41; the cylinder 4 is provided with a communication inner chamber 41 or a communication piston 3 The hydraulic oil supply channel 43 in the closed space surrounded by the inner cavity 41, the side wall of the cylinder body 4 is provided with a static pressure oil supply port 42, and the top surface of the piston 3 is provided with at least one circumferentially closed oil chamber 12, and the inside of the piston 3 A static pressure oil supply passage connecting the oil chamber 12 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com