Method of preparing transition metal dichalcogenide (TMD)

A technology of transition metals and chalcogenides, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems that the number of film layers is difficult to control, and it is difficult to apply to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

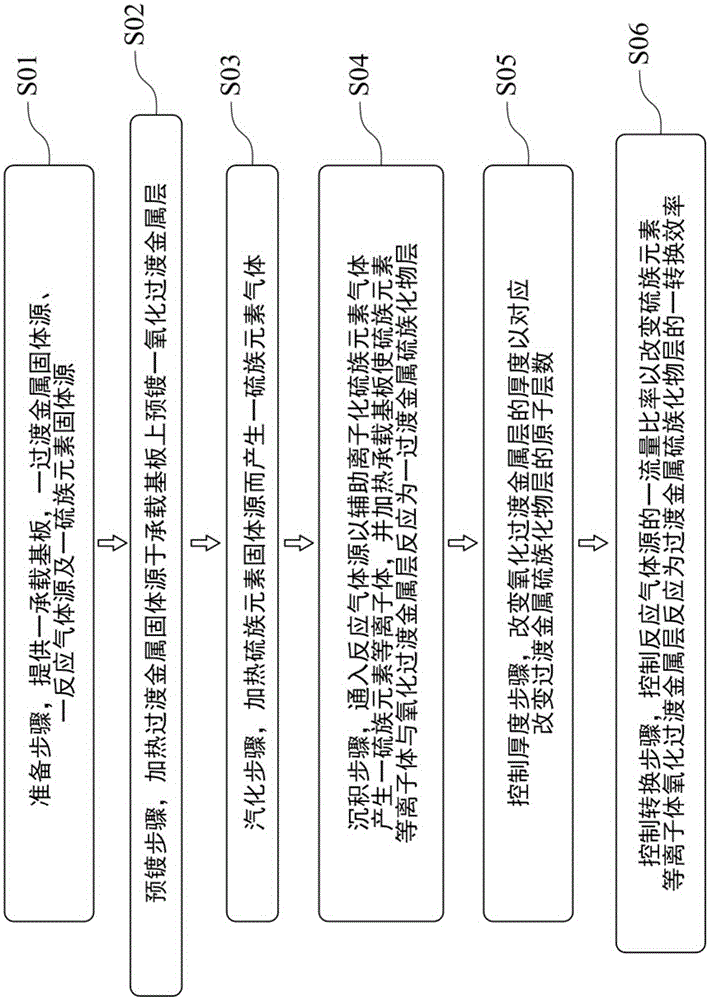

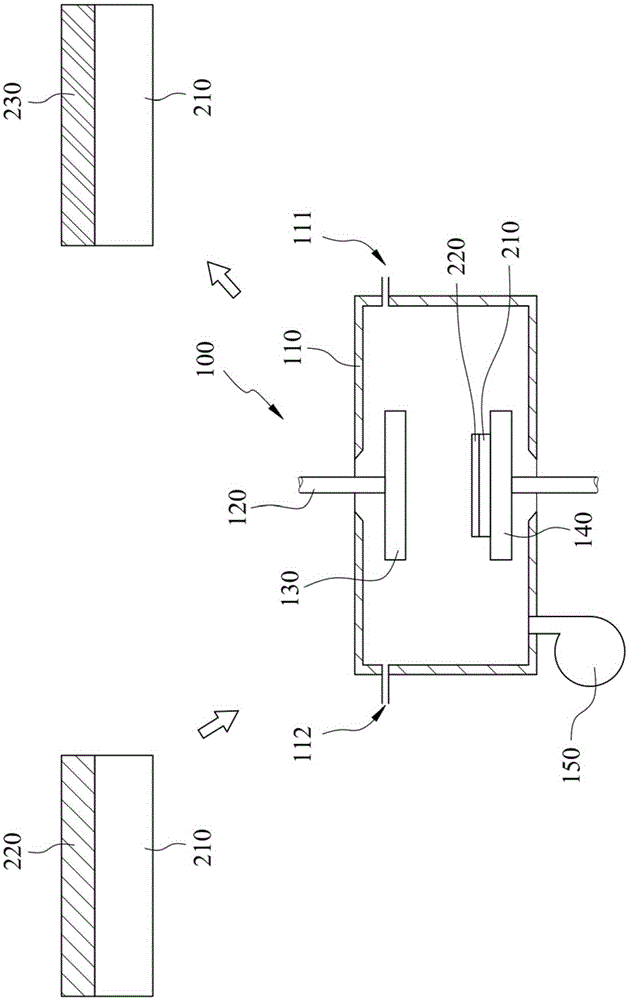

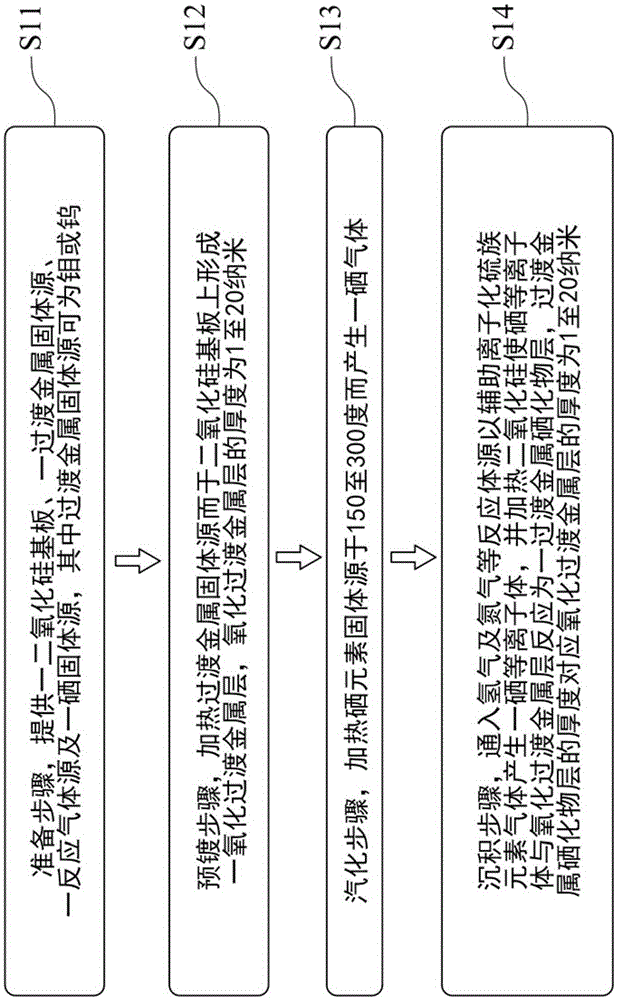

[0049] Please refer to figure 1 and figure 2 ,in figure 1 is a flowchart illustrating a method for preparing transition metal chalcogenides. figure 2 is to draw figure 1 Schematic diagram of the preparation of transition metal chalcogenides. In this embodiment, a plasma-assisted processing system 100 is used to prepare transition metal chalcogenides, so the figure 2 The structure of the plasma-assisted processing system 100 shown in , which includes a reaction chamber 110 , a radio frequency generator 120 , an electrode 130 , a heater 140 and a vacuum pump 150 . The reaction chamber 110 has a first gas inlet 111 and a second gas inlet 112. The first gas inlet 111 is used to deliver the gas and nitrogen generated by heating the chalcogen solid source, and the second gas inlet 112 is used to deliver hydrogen. , as a source of auxiliary plasma generation.

[0050] The method for preparing transition metal chalcogenides, the steps include the following steps:

[0051] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com