Method for removing hydrogen sulfide in biogas through combination of iron-containing compound and Acidithiobacillus caldus

A technology of acidic thiobacillus and iron compounds, which is applied in the direction of chemical instruments and methods, separation methods, bacteria, etc., can solve the problem that the desulfurization stability is easily affected by the ambient temperature, etc., to achieve reduced amount, high removal efficiency, Effect of reducing cost and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

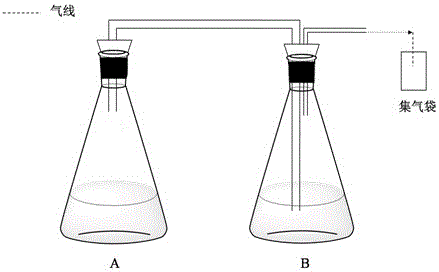

[0027] This embodiment provides a method of adding different concentrations of FeCl 2 On-line desulfurization and biological desulfurization by adding mesophilic acidophilic thiobacterium strains were used to jointly remove hydrogen sulfide from biogas.

[0028]Step 1: Carry out recovery culture of mesophilic acidophilus Thiobacillus strain, draw 0.3~0.5mL of 9K medium with a sterile pipette, drop it into the ampoule, shake gently, so that the freeze-dried bacteria dissolve and form a suspension, absorb all The bacterial suspension was transferred to 5 mL of 9K medium, and the stirring speed was 170 r / min, and the temperature was 40-45 ° C for 48-72 hours. Since the strains were stored in freeze-drying, the lag period was long, so the cultured one generation The mesophilic acidophilus thiobacillus culture solution was inoculated into 5mL liquid medium at an inoculum volume of 3%~5%, and the same culture conditions were carried out for two consecutive subcultures, and the recov...

Embodiment 2

[0042] This embodiment provides a method of adding different concentrations of Fe(OH) 3 On-line desulfurization and biological desulfurization by adding mesophilic acidophilic thiobacterium strains were used to jointly remove hydrogen sulfide from biogas.

[0043] Step 1, take 7 groups of desulfurization devices, numbered C0 to C6, and add 80mL of the fermentation broth obtained in step 2 to each desulfurization device A;

[0044] Step 2: Take 7 groups of combined desulfurization devices, numbered D0 to D6, add 80 mL of the fermentation broth obtained in step 2 of Example 1 to each combined desulfurization device A, add 80 mL of 9K medium to each combined desulfurization device B, and inoculate 3%~ 5% the mesophilic acidophilus bacterium liquid obtained in step 1 of embodiment 1;

[0045] Step 3, do a blank test without adding iron-containing compounds to the A device of C0, and add Fe(OH) to the A device of C1-C6 in sequence 3 The amount is 0.16mmol, 0.32 mmol, 0.64 mmol, 0...

Embodiment 3

[0055] This embodiment provides a kind of Fe(OH) 3 , FeCl 2 and FeCl 3 According to the online desulfurization mixed in different proportions and the biological desulfurization with mesophilic acidophilus thiobacterium strains, the experiment of joint removal of hydrogen sulfide in biogas was carried out.

[0056] Step 1: Take 8 groups of desulfurization devices, numbered E0 to E7, and add 80 mL of the fermentation broth obtained in step 2 to each desulfurization device A;

[0057] Step 2: Take 8 groups of combined desulfurization devices, numbered F0 to F7, add 80 mL of the fermentation broth obtained in step 2 of Example 1 to each combined desulfurization device A, add 80 mL of 9K medium to each combined desulfurization device B, and inoculate 3%~ 5% the mesophilic acidophilus bacterium liquid obtained in step 1 of embodiment 1;

[0058] Step 3, use No. E0 A device as a blank test without adding iron-containing compounds, and add 2.88mmol FeCl in turn to E1-E7 A devices ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com