A method of comprehensively utilizing C4 fractions after etherification

A technology for post-ether carbon 4 and distillate, applied in the petrochemical field, can solve the problem of high energy consumption, and achieve the effects of simple process, low production cost and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Reaction material: Acetic acid is glacial acetic acid with a purity greater than 99.5%. The C4 fraction after ether includes isobutane 44.19%, n-butane 13.23%, 1-butene 14.05%, t-2-butene 16.55%, and isobutene 0.23% And c-2-butene 11.75%, the water is deionized water, the catalyst adopts H-type macroporous strong acid styrene series cationic resin, the brand is NKC-9, and the two reactors are respectively equipped with 50g catalyst.

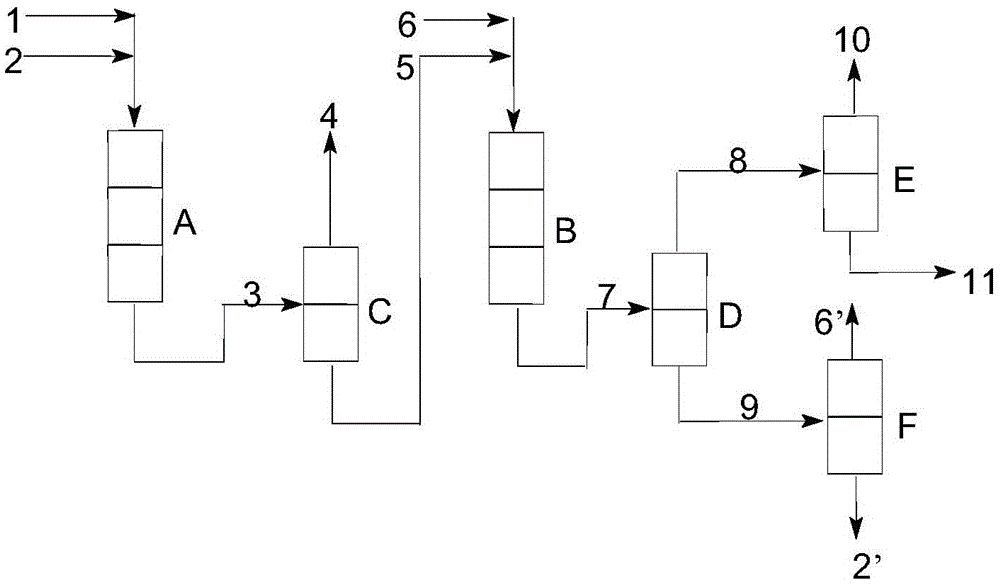

[0047] Step i: After ether, C4 fraction 1 and acetic acid 2 are fed from the top of the first reactor A with a metering pump, and reacted under the action of a catalyst to obtain a mixture 3. The reaction conditions are: the catalyst bed temperature is 90℃, the pressure is 1.5MPa, the molar ratio of C4 olefin to acetic acid in the C4 fraction is 0.8, and the weight space velocity of the C4 fraction is 2h -1 .

[0048] The mixture 3 flows from the bottom of the first reactor into the first separation tower C for gas-liquid separation, carbon tet...

Embodiment 2

[0055] Preparation of modified H-type macroporous strong acid styrene series cationic resin NKC-9:

[0056] Add 2.0 g of sulfamic acid and 200 ml of methanol into a 500-ml round bottom flask, and stir to dissolve the sulfamic acid. Add 180 grams of NKC-9 resin and the methanol solution with sulfamic acid dissolved into the autoclave. Install the reactor and heat it to 80℃ with stirring. After 2 hours, the temperature will be lowered and the stirring will be stopped. The temperature of the reactor will drop. After reaching room temperature, the reaction kettle was disassembled, the catalyst was poured out, dried and then baked at 80°C for 4 hours, then taken out and placed in a desiccator for later use.

[0057] Reaction raw materials: acetic acid is glacial acetic acid with a purity greater than 99.5%. The C4 fraction after ether includes 0.25% of isobutane, 20.45% of n-butane, 5.31% of 1-butene, 43.72% of t-2-butene, and 0.10% of isobutene. , C-2-butene 30.17%, water is deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com