Waste collection method of glass cutting machine

A waste collection and cutting machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of low efficiency of collecting glass crumbs, achieve the effects of preventing splashing everywhere, speeding up collection efficiency, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

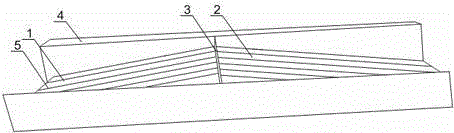

[0018] Such as figure 1 As shown, the present invention first places the collector at the bottom of the cutting table, and sets a plurality of successively connected broken particle collection units, which can be applied to a single or glass cutting production line for the processing of broken particles after glass processing. The collector is composed of a bottom plate. The two inclined surfaces formed by connecting A and bottom plate B make it more labor-saving and quicker to collect glass cullet. The grooves on bottom plate A and bottom plate B are respectively arranged to facilitate the glass cullet to quickly slide out of the bottom plate to be collected during collection and cleaning. , Improve the efficiency of particle collection; wherein the collector includes a plurality of sequentially connected particle collection units, the waste collection unit includes an inclined bottom plate A, an inclined bottom plate B and a connecting block, the top of the bottom plate A and ...

Embodiment 2

[0020] Such as figure 1 As shown, in this embodiment on the basis of embodiment 1, the waste collection unit is further provided with two side baffles 4. The bottom plate A1 and the bottom plate B2 are respectively connected to the two side baffles 4, and the two side baffles 4 Connected by the connecting block 3, the additional two side baffles 4 of the waste collection unit can make the bottom plate A1, the bottom plate B2 and the connecting block 3 respectively constitute two closed collection units, which can effectively prevent glass particles from being splashed around and accelerate the collection rate ; The groove 5 on the bottom plate A1 and the groove 5 on the bottom plate B2 are parallel to the axis of the bottom plate A1 and the bottom plate B2, respectively, and the groove 5 is set to speed up the glass particles or oil when collecting or cleaning Moving, the groove 5 is consistent with the axis directions of the bottom plate A1 and the bottom plate B2, which facil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com