Developing embolic material and preparation method thereof

A technology of embolization and microspheres, which is applied in the fields of surgery, surgical adhesives, medical science, etc., can solve the problems of toxic and side effects, ectopic embolism, incompleteness, etc., and achieves good biocompatibility, good development effect, and simple and fast cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

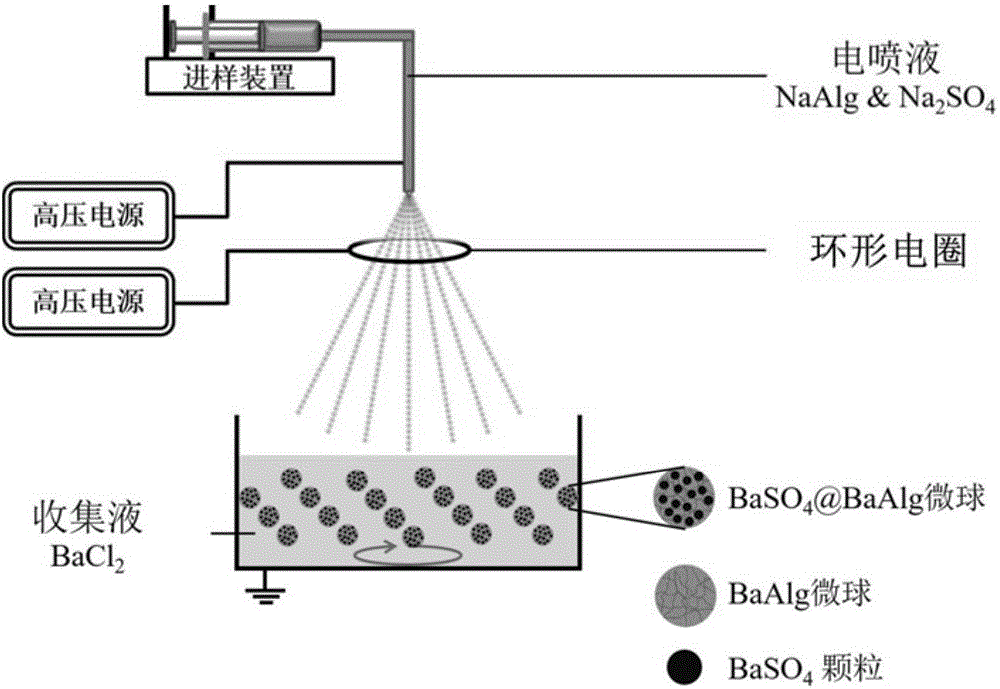

[0039] Example 1: Preparation of barium alginate microspheres loaded with barium sulfate

[0040] 2% (w / v) sodium alginate and 0.3 mol / L sodium sulfate were used as the electrospray liquid and put into the sampling device of the electrostatic spraying equipment, and the sampling speed was adjusted to 0.3 mL / hr. Use 0.6mol / L barium chloride solution as the collection liquid, place it 9cm directly below the nozzle, and slowly stir the collection liquid. The ring electric coil is placed 2cm below the nozzle to limit the spraying range of the droplets. The inner diameter of the nozzle is 0.18mm. The nozzle is connected to a DC high-voltage power supply, and the adjusted voltage is 10kv. The ring electric coil is connected to another high-voltage power supply, and the regulating voltage is 2kv. Collection dish ground wire. Turn on the DC high-voltage power supply, and the electrospray liquid is split into micron-sized droplets with uniform particle size by electrostatic force, ...

Embodiment 2

[0042] Embodiment 2: the control of developing microsphere particle size

[0043] The preparation method is consistent with Example 1. This example is only used to list some examples, showing that monodisperse microspheres with different particle sizes can be obtained by simply adjusting the parameters of electrostatic spraying, which can be applied to blood vessel embolization with different calibers.

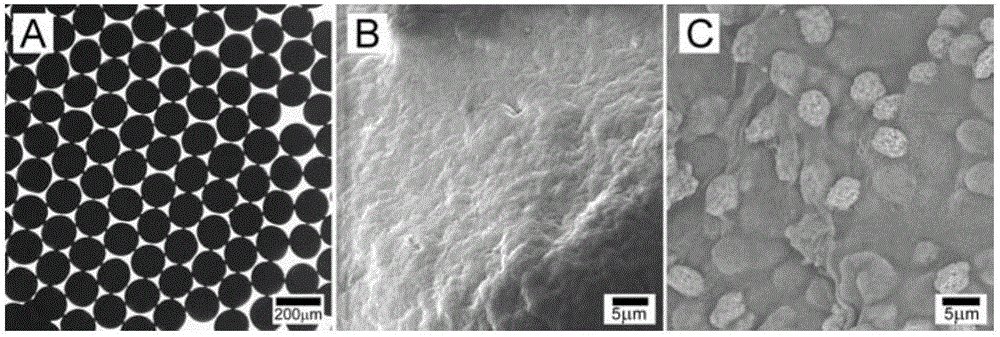

[0044] When keeping other parameters of electrostatic spraying constant and only increasing the inner diameter of the nozzle, the particle size of embolism microspheres increases accordingly. Such as Figure 4 As shown, when the inner diameter of the nozzle increases from 0.18mm, 0.26mm, 0.41mm, 0.84mm to 1.19mm, the particle size of the microspheres increases from 160±7μm, 220±18μm, 320±17μm, 410±27μm to 490 ± 23 μm. The morphology of the obtained developed microspheres is as follows: Figure 5 As shown, 5A-5E represent the optical micrographs of the developed microsphere...

Embodiment 3

[0046] Embodiment 3: Expansion of the preparation method of developing microspheres

[0047] The preparation method is consistent with Example 1. This example is only used to enumerate some examples to prove that the preparation method of the present invention is easy to expand.

[0048] Such as Figure 8 As shown, when the other parameters of electrostatic spraying are kept constant and the injection speed is increased from 0.3mL / hr, 0.6mL / hr, 1mL / hr to 2mL / hr, the particle diameters of the obtained microspheres are 160±7μm, 164 ±9 μm, 170±11 μm, and 168±9 μm. The morphology of the obtained developed microspheres is as follows: Figure 9 As shown, 9A-9D represent the optical micrographs of the microspheres prepared when the injection speed was 0.3, 0.6, 1 and 2 mL / hr, respectively. The particle size and monodispersity of the microspheres did not change much. That is, when the yield is increased by about 10 times, the quality of the developed microspheres is still within ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com