Space electrostatic protection solar cell array interconnection package structure and method

A technology for solar cell arrays and electrostatic protection, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low reliability of solar cell arrays, and achieve the effects of automatic manufacturing process, stable space, and good process inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the design and examples of the present invention will be further described in conjunction with the drawings and embodiments.

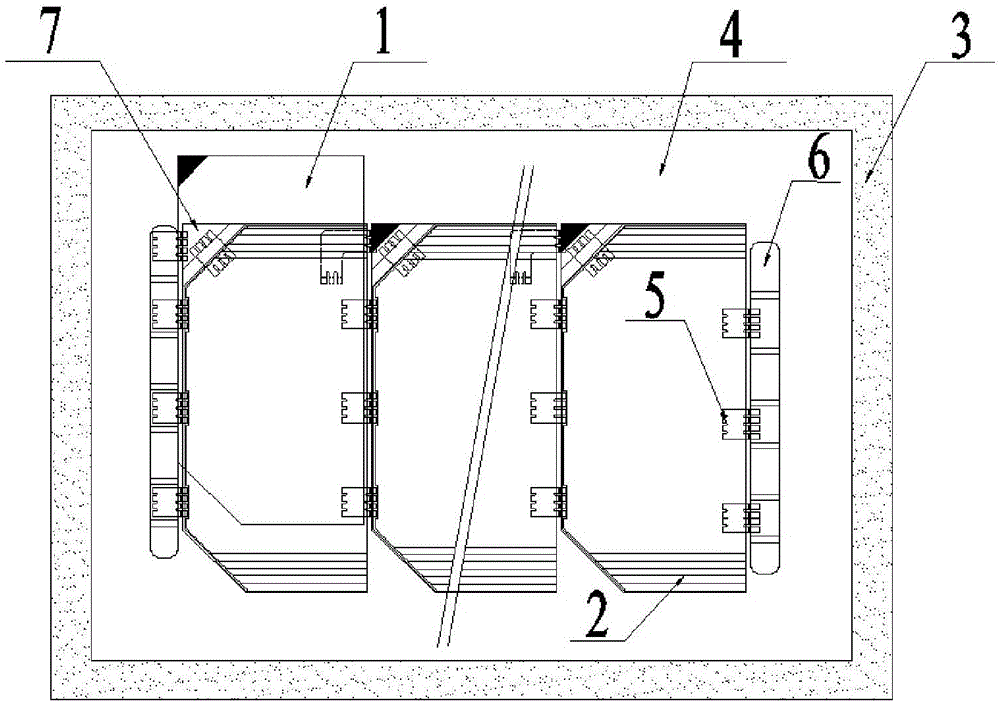

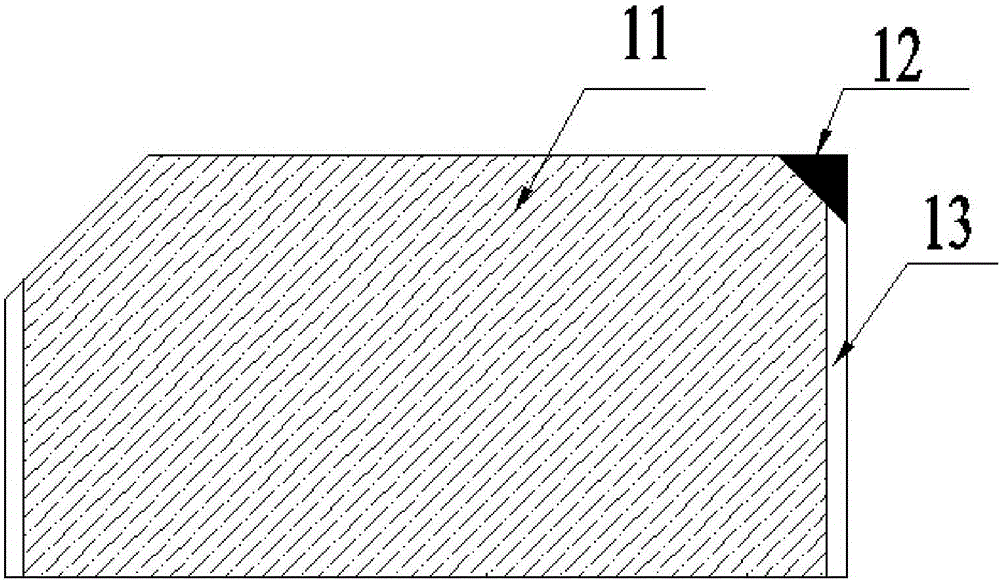

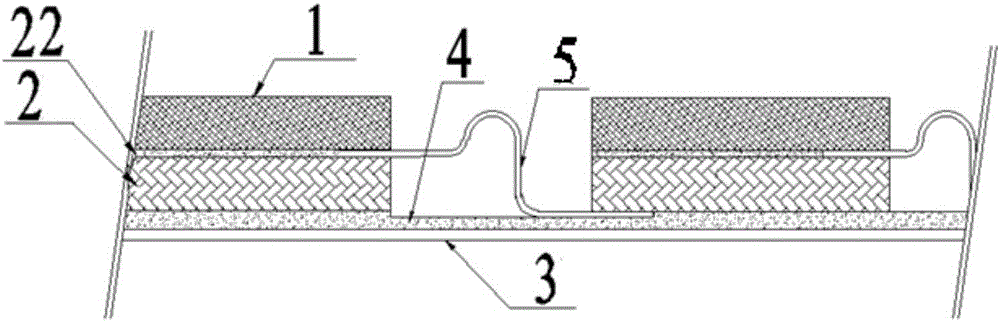

[0031] Such as figure 1 As shown, the space static electricity protection solar cell array interconnection package structure provided by the embodiment of the present invention includes: a substrate 3, a solar cell 2, an anti-irradiation conductive glass cover sheet 1; the surface of the substrate 3 is coated with a layer of high-resistance conductive glue 4. Paste the solar cell 2 on the surface of the substrate 3. The solar cell 2 is connected in parallel with the bypass diode 7 at a missing corner, and the conductive layer of the anti-irradiation conductive glass cover sheet 1 is far away from the solar cell 2 and covers the surface of the solar cell 2 The upper and lower surfaces of one corner of the radiation-resistant conductive glass cover sheet 1 and the corresponding side surfaces are plated with a metal film 12 (see figure 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com