Method for improving conductivity and transmittance of silver nanowire transparent conductive film

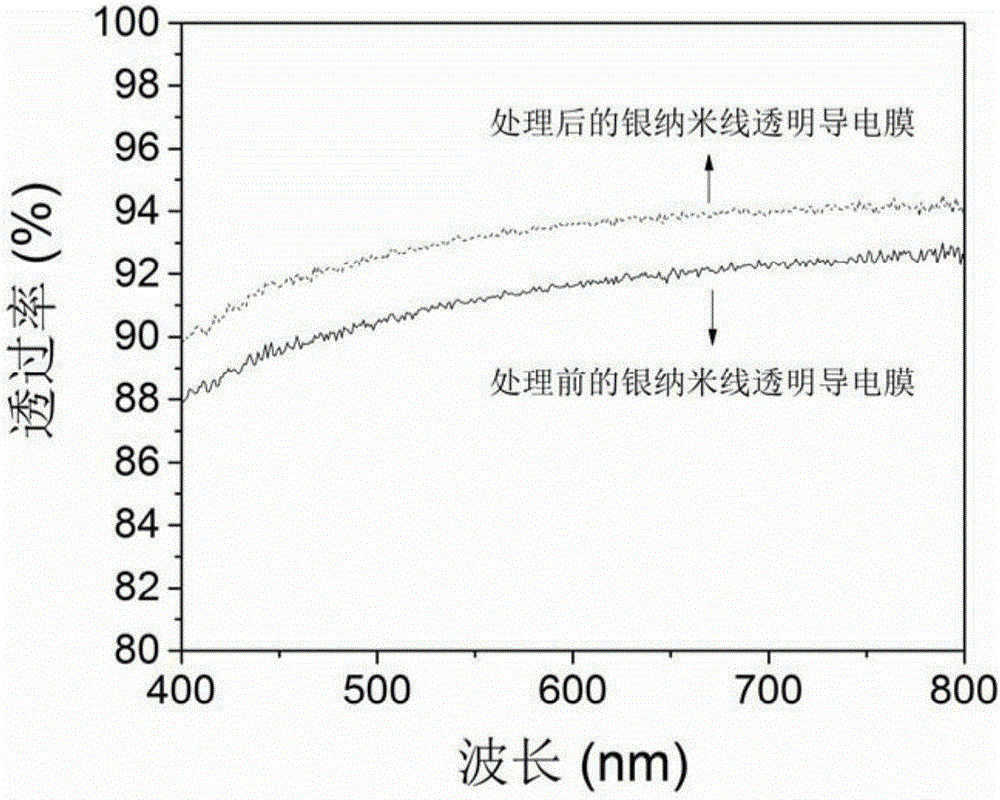

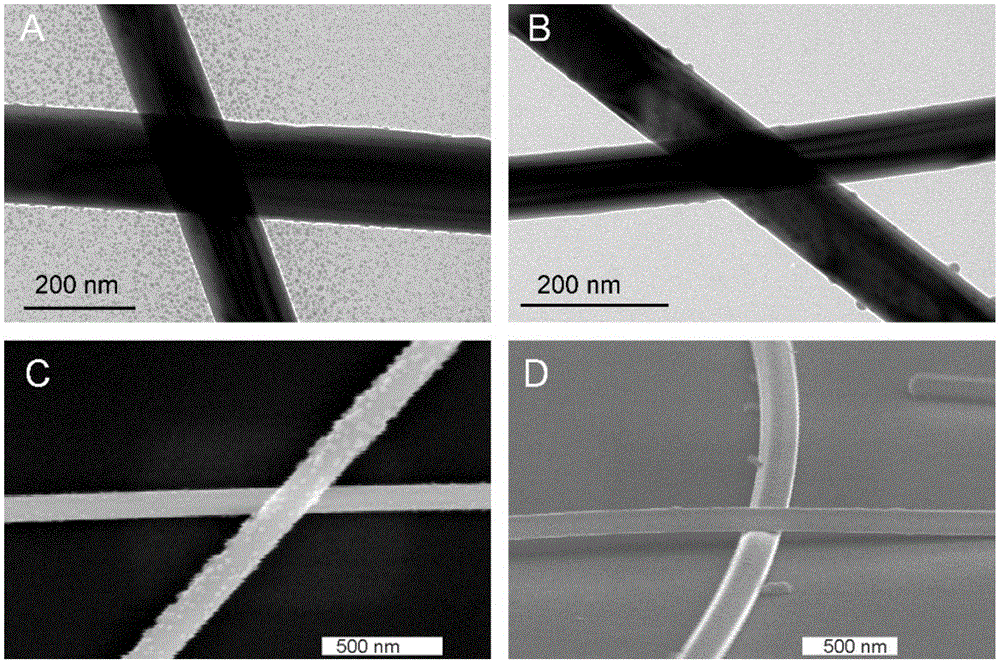

A technology of transparent conductive film and silver nanowire, which is applied in the field of nanometers, can solve the problems of simultaneously improving the electrical conductivity and optical transmittance of silver nanowire transparent conductive film, increasing the volume of silver nanowire, and reducing optical performance, so as to achieve junction resistance. The effect of reducing, low cost, and improving transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The method for improving the conductivity and transmittance of the silver nanowire transparent conductive film of embodiment 1 comprises the following steps:

[0020] (1) prepare silver nanowire transparent conductive film, this silver nanowire transparent conductive film comprises substrate and the silver nanowire conductive network that is arranged on this substrate unilateral surface, and this silver nanowire conductive network is coated with polyvinylpyrrolidone by surface Silver nanowires are formed; the quaternary ammonium salt surfactant is dissolved in a solvent to prepare 100mL of an aqueous solution of dodecyltrimethylammonium bromide with a concentration of 0.0001mol / L;

[0021] (2) Soak the prepared silver nanowire transparent conductive film in the aqueous solution of dodecyltrimethylammonium bromide prepared for 100min;

[0022] (3) The silver nanowire transparent conductive film is taken out from the aqueous solution of dodecyltrimethylammonium bromide, r...

Embodiment 2

[0025] The method for improving the conductivity and transmittance of the silver nanowire transparent conductive film of embodiment 2 comprises the following steps:

[0026] (1) prepare silver nanowire transparent conductive film, this silver nanowire transparent conductive film comprises substrate and the silver nanowire conductive network that is arranged on this substrate unilateral surface, and this silver nanowire conductive network is coated with polyvinylpyrrolidone by surface Silver nanowires are formed; the quaternary ammonium salt surfactant is dissolved in a solvent to prepare 100mL of an ethanol solution of dodecyltrimethylammonium bromide with a concentration of 0.001mol / L;

[0027] (2) Soak the prepared silver nanowire transparent conductive film in the ethanol solution of dodecyltrimethylammonium bromide prepared for 50min;

[0028] (3) Take out the silver nanowire transparent conductive film from the ethanolic solution of dodecyltrimethylammonium bromide, dry a...

Embodiment 3

[0031] The method for improving the conductivity and transmittance of the silver nanowire transparent conductive film of embodiment 3 may further comprise the steps:

[0032] (1) prepare silver nanowire transparent conductive film, this silver nanowire transparent conductive film comprises substrate and the silver nanowire conductive network that is arranged on this substrate unilateral surface, and this silver nanowire conductive network is coated with polyvinylpyrrolidone by surface Silver nanowires are formed; the quaternary ammonium salt surfactant is dissolved in a solvent to prepare a 100mL aqueous solution of tetradecyltrimethylammonium bromide with a concentration of 0.005mol / L;

[0033] (2) Soak the prepared silver nanowire transparent conductive film in the prepared tetradecyltrimethylammonium bromide aqueous solution for 30min;

[0034] (3) The transparent conductive film of silver nanowires is taken out from the aqueous solution of tetradecyltrimethylammonium bromi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com