Online forecasting method of pH value of ore pulp in bauxite flotation process

A technology of flotation process and prediction method, which is applied in the direction of testing pH value, using chemical indicators for analysis, etc., can solve the problems that cannot be used to solve pH value control, has no online control method, and relies on manual experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

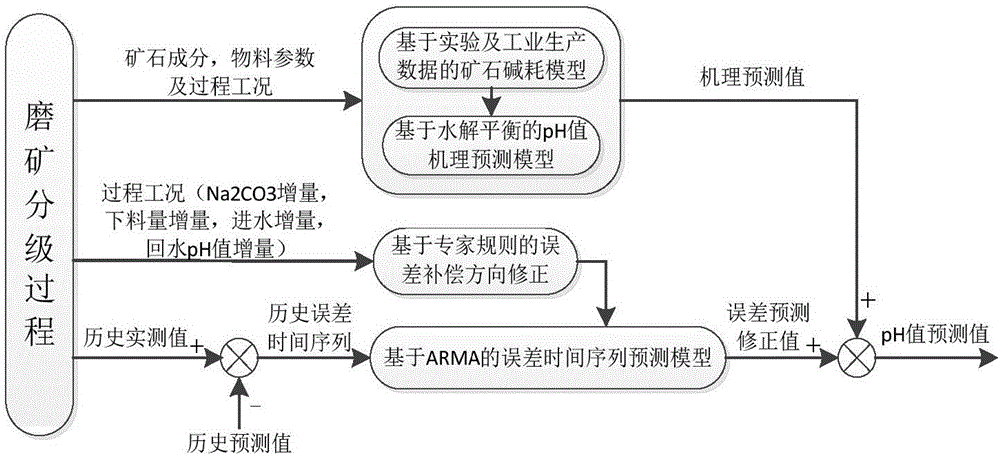

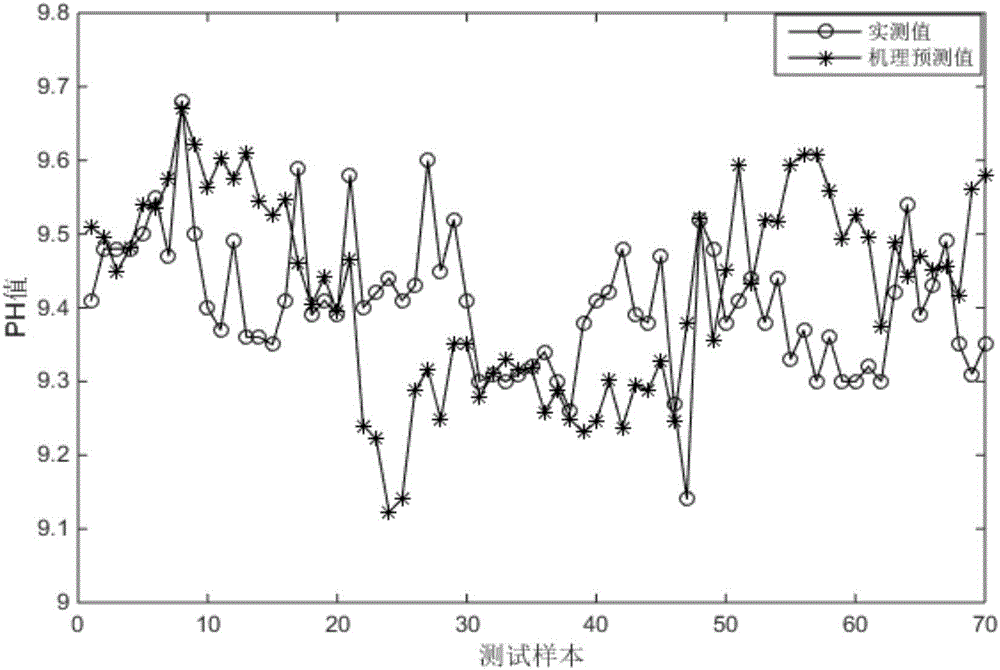

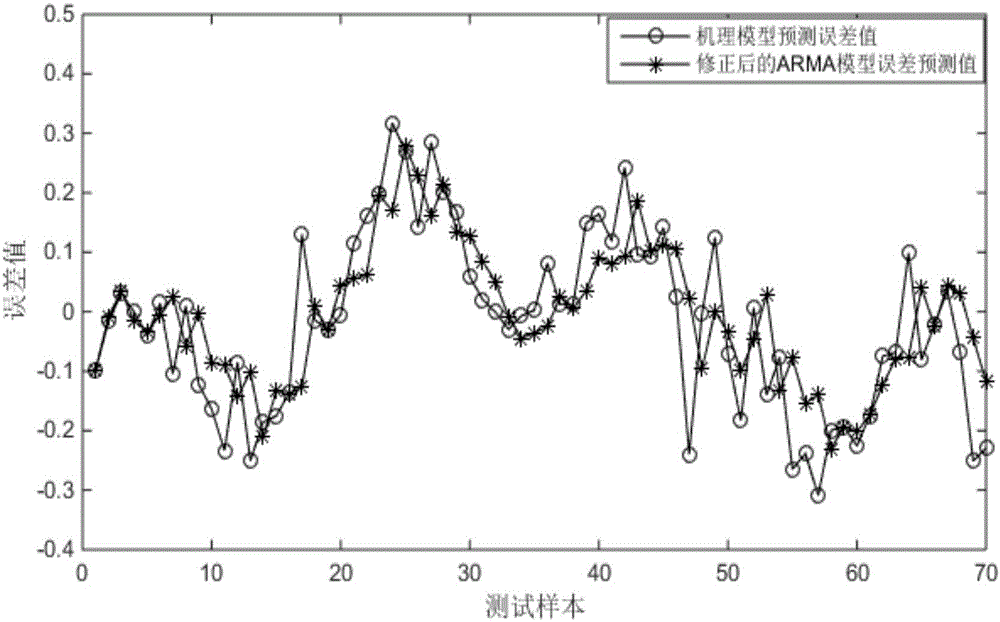

[0050] Such as figure 1 As shown, the present invention utilizes the regression model of ore alkali consumption based on industrial production data, the mechanism model based on the chemical principle of flotation solution, and the error compensation prediction model based on autoregressive sliding average to realize the prediction of the pH of flotation pulp. Here, 285 sets of continuous production data of a bauxite concentrator are used as a case analysis (excluding data under abnormal working conditions), of which the first 215 sets of data are used for parameter identification, and the last 70 sets of data are used for effect verification.

[0051] 1. Regression model of ore alkali consumption

[0052] The reaction between the ore and the alkali will consume part of the alkali, so that all the alkali added to the pulp cannot be used to adjust the pH value of the pulp; at the same time, because the diaspore ore contains diaspore, chlorite, iron ore Ore, titanium ore, illit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com