Boiler waste heat recovery device with adjustable smoke removing sheets

A boiler waste heat recovery device technology, applied to heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems affecting the environment, etc., and achieve the effect of large contact area, good smoke removal effect, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

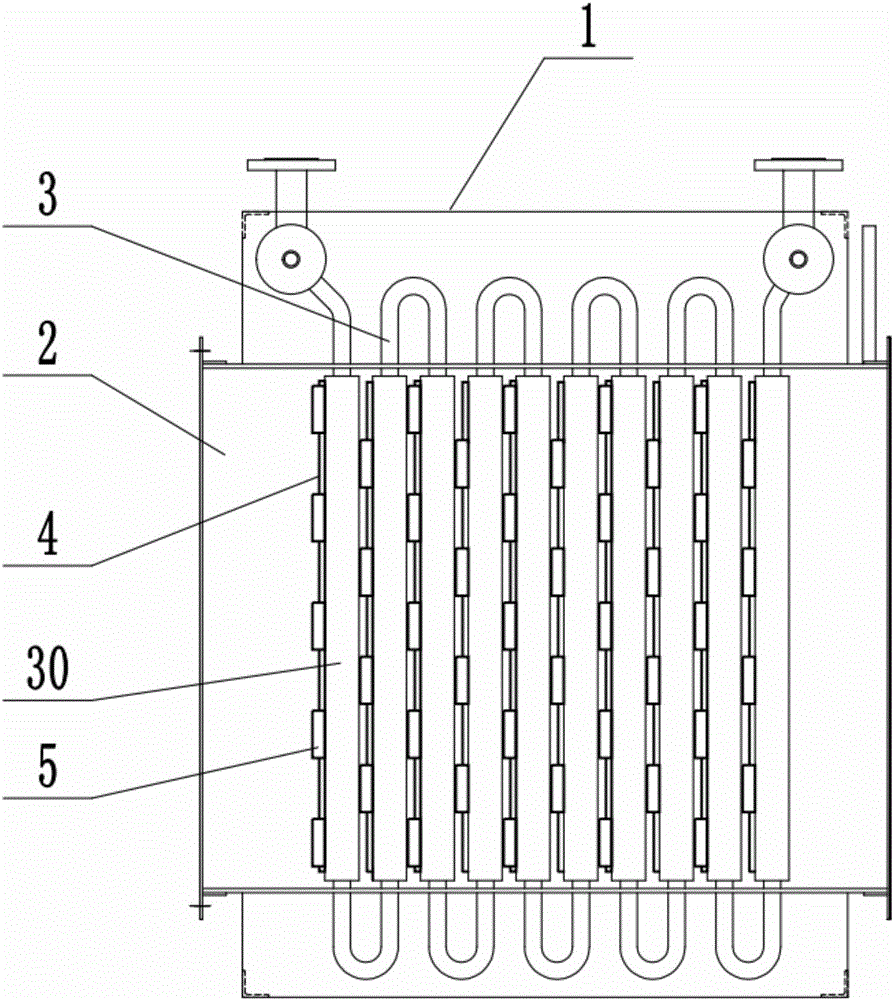

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] like figure 1 As shown, the boiler waste heat recovery device with adjustable smoke removal sheet in this embodiment includes a flue gas channel 2 installed on the bracket 1, and a serpentine tube 3 placed in the flue gas channel 2 is fixedly installed on the bracket 1 , the vertical section 30 of the serpentine pipe 3 is equipped with a bar-shaped installation groove 4 parallel to its extension direction, and a smoke-removing sheet 5 is installed in the bar-shaped installation groove 4, and the smoke-removing sheet 5 can be installed in the bar-shaped installation groove 4 Move and adjust the spacing; the smoke removal sheets 5 between the adjacent vertical sections 30 of the serpentine pipe 3 are arranged in a staggered manner.

[0013] A plurality of bar-shaped installation grooves 4 are installed on the peripheral surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com