Electrolytic aluminum flue gas quantity and contaminant zero-deviation emission system

An electrolytic aluminum and zero-emission technology, which is applied in gas treatment, combustion methods, and dispersed particle filtration, can solve the problems of large electrolytic aluminum flue gas emissions, environmental damage, and large flue gas volume, so as to reduce equipment investment and Operating cost, the effect that the impact is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

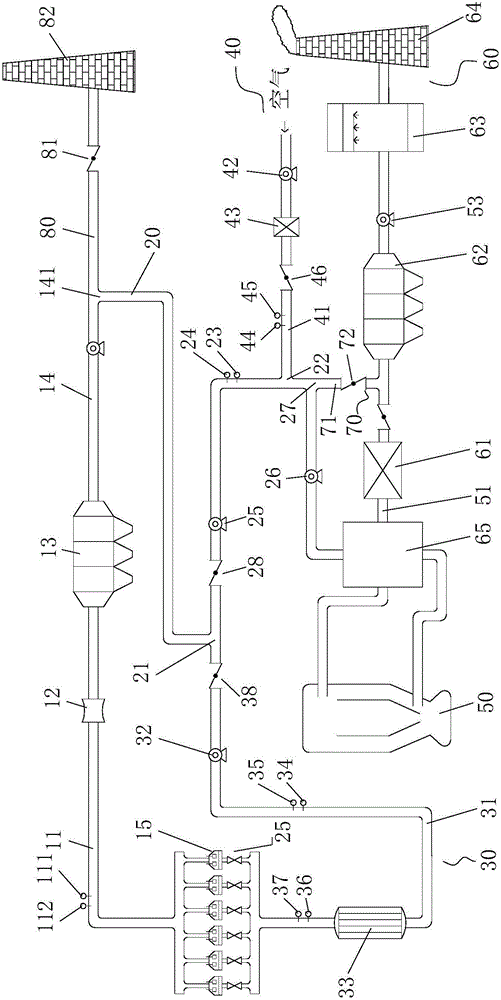

[0044] according to figure 1 As shown, the electrolytic aluminum flue gas volume and pollutant discharge system of the present invention are illustrated. The zero emission system includes electrolytic aluminum flue gas defluorination and dust removal unit 10 and combustion equipment 50 .

[0045] The electrolytic aluminum flue gas defluorination and dust removal unit 10 can be conventionally used in the treatment process of the existing electrolytic aluminum flue gas, and generally includes the main exhaust pipe 11 of the electrolytic cell, the defluorination equipment 12, the dust removal equipment 13 and the emptying pipeline 14. One port of the main smoke exhaust pipe 11 of the electrolytic cell is connected to the main smoke exhaust port of the electrolytic aluminum workshop, and the other port is connected to the flue gas of the defluorination equipment 12 (such as alumina dry defluorination equipment, Venturi reactor). Gas inlet connection; the flue gas inlet exhaust po...

Embodiment 2

[0058] In the above-mentioned electrolytic aluminum flue gas volume and pollutant zero discharge system in Embodiment 1 of the present invention, since the flow and temperature of the electrolytic aluminum flue gas in each unit need to be monitored, the flow and / or temperature in each unit Therefore, a control unit is added in the present invention to realize the automation of the above-mentioned monitoring and regulation, as well as to ensure the reasonable distribution of the entire electrolytic aluminum flue gas volume and the zero pollutant emission system, and to ensure the normal operation of the system.

[0059] Such as figure 1 As shown, the control unit includes a processor (not shown in the figure) and a plurality of sensor groups, and each sensor group of the plurality of sensor groups is configured as a unit. Specifically, each sensor group may include a pressure sensor and / or a temperature sensor to collect the pressure, flow and temperature parameters of the flue...

Embodiment 3

[0071] On the basis of the above-mentioned embodiment 1 and embodiment 2, the zero emission system of the present invention also includes the exhaust gas treatment unit 60 of the combustion equipment 50, and the exhaust gas treatment unit 60 of the combustion equipment includes an air preheater 65, a low temperature Economizer 61, dust removal device 62 and desulfurization device 63. The air preheater 65 is connected to the high-temperature flue gas generated by the combustion equipment 50 as a heat source to heat the combustion-supporting gas; the combustion flue gas of the air preheater 65 After the outlet of the outlet, the low-temperature economizer 61, dust removal device 62 and desulfurization device (desulfurization tower) 63 are connected in sequence. Such as figure 1 As shown in , an air preheater 65, a low-temperature economizer 61, a dust removal device 62 and a desulfurization device 63 are arranged in sequence on the exhaust pipe 51 of the combustion equipment 50,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com