A four-way switching valve provided with a direct-acting electromagnetic valve and it as a pilot valve

A technology of four-way switching valve and solenoid valve, which is applied to multi-way valves, valve devices, mechanical equipment, etc., can solve problems such as noise and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

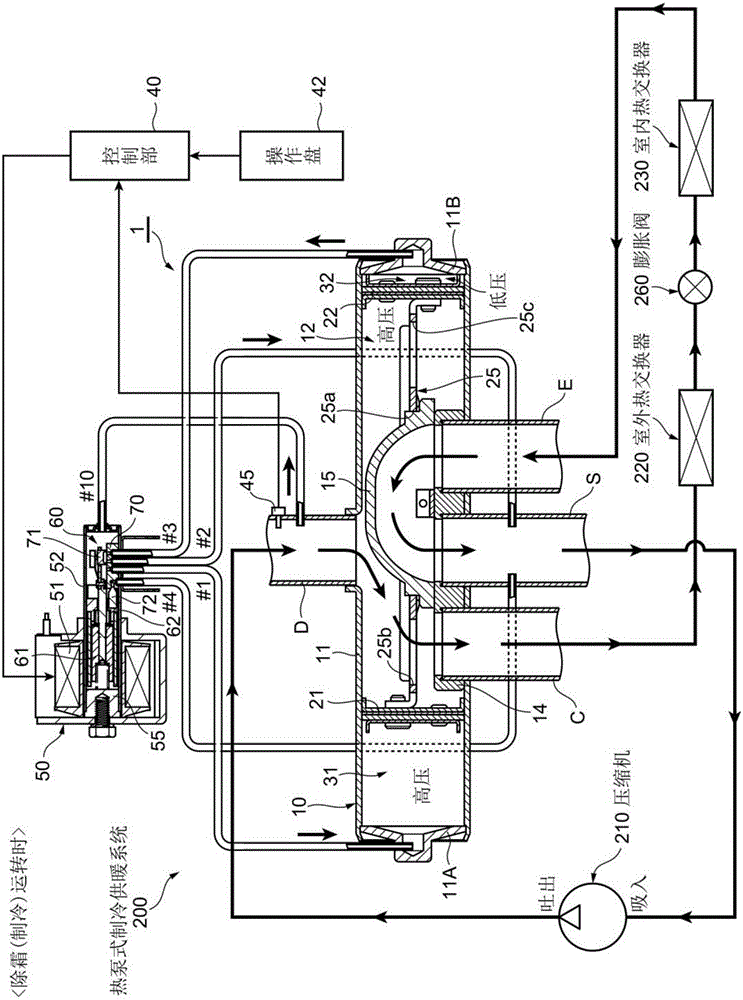

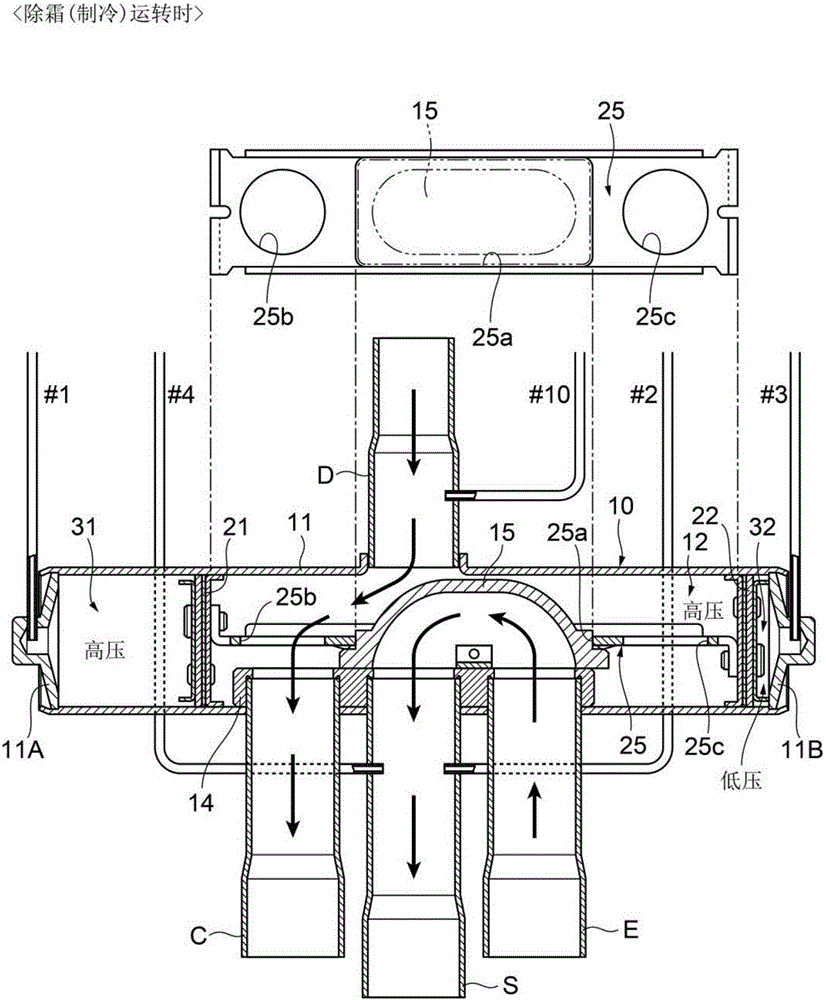

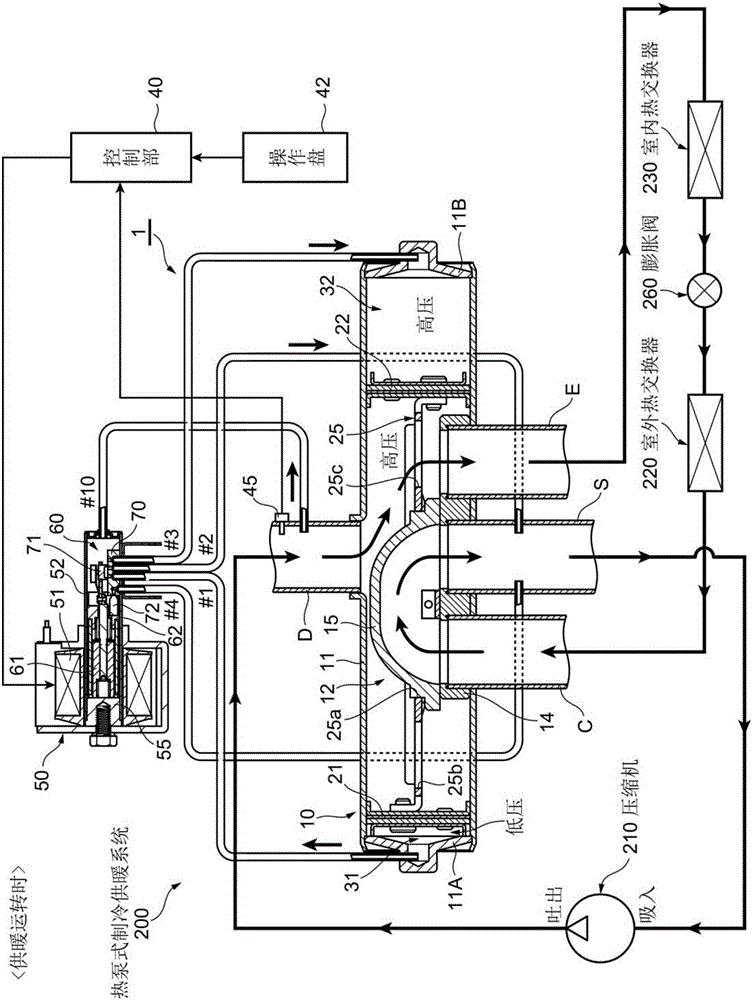

[0059] figure 1 It is an overall configuration diagram showing a cooling operation (during defrosting operation) of a heat pump type cooling and heating system incorporating the first embodiment of the direct acting solenoid valve according to the present invention as a pilot valve. Sliding four-way switching valve, figure 2 yes means figure 1 A cross-sectional view with a partial plan view of the four-way valve body of the shown four-way switching valve during cooling operation (during defrosting operation), image 3 It is an overall structural diagram showing the heating operation of the heat pump cooling and heating system, which is assembled with figure 1 The sliding four-way switching valve shown, Figure 4 yes means figure 1 An enlarged cross-sectional view with a partial plan view of the direct-acting solenoid valve of the first embodiment as a pilot valve of the four-way switching valve shown during cooling operation (during defrosting operation).

[0060] In...

no. 2 approach

[0141] Figure 12A It is a side view showing the rotary four-way switching valve equipped with the second embodiment of the direct acting solenoid valve of the present invention as a pilot valve, Figure 12B It is an upper surface side arrangement diagram of the cooling position and an upper surface side arrangement diagram of the heating position of the rotary four-way switching valve provided with the second embodiment of the direct acting solenoid valve of the present invention as a pilot valve. Figure 13 It is an overall configuration diagram showing the cooling operation (defrosting operation) of the heat pump cooling and heating system incorporating the Figure 12A , Figure 12B The rotary four-way switching valve shown (shown is Figure 12B X-X profile of the refrigeration position). Figure 14 It is an overall structural diagram showing the heating operation of the heat pump cooling and heating system, which is assembled with Figure 12A , Figure 12B The rotary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com