A marine diesel engine tail gas waste heat temperature difference energy utilization device

A marine diesel engine and temperature difference energy technology, applied in the direction of exhaust devices, noise reduction devices, mechanical equipment, etc., can solve the problems of affecting work efficiency, wasting energy, damaging power generation chips, etc., and achieve comprehensive and efficient utilization of cold energy and heat energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following are specific embodiments of the present invention, and further describe the technical solution of the present invention in conjunction with the accompanying drawings, but the present invention is not limited to these embodiments.

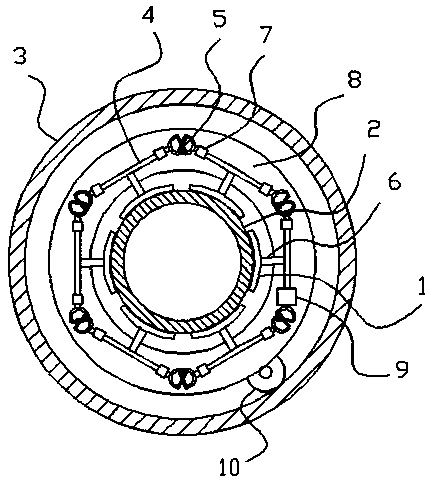

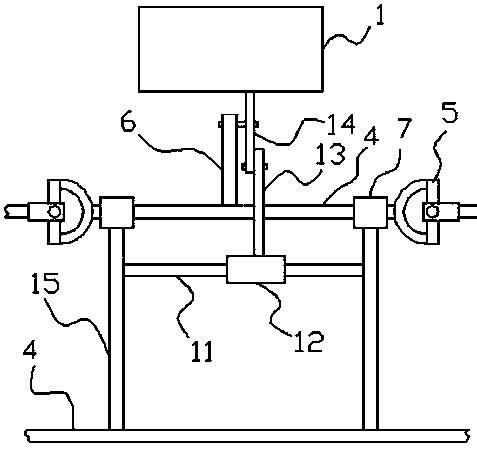

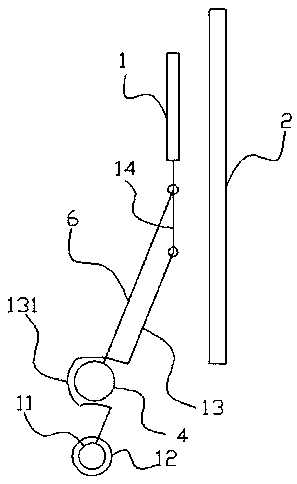

[0016] Such as figure 1 As shown, a marine diesel engine exhaust waste heat temperature difference energy utilization device includes a semiconductor thermoelectric power generation chip 1 and a coaxial cooling sleeve 3 that is placed outside the engine exhaust discharge pipe 2 . A cooling water pipe is coiled outside the cooling sleeve for connecting the water of the cooling source. A frame body is arranged between the exhaust gas discharge pipe and the cooling sleeve, and the frame body is a regular hexagon frame body formed by connecting the rotating shafts 4 end to end. The crank rod 6 perpendicular to the rotating shaft. Each rotating shaft is provided with a bearing 7, and an annular turntable is arranged between the tai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com