Formula and production technology of artificial waterborne polyurethane foamed synthetic leather

A water-based polyurethane and production process technology, applied in polyurea/polyurethane coatings, coatings, dyeing methods, etc., can solve the problems of endangering the health of employees, environmental pollution, and high energy consumption in drying, and achieve a clean and environmentally friendly production process. The effect of simple process flow and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: artificial leather high light embossed synthetic leather

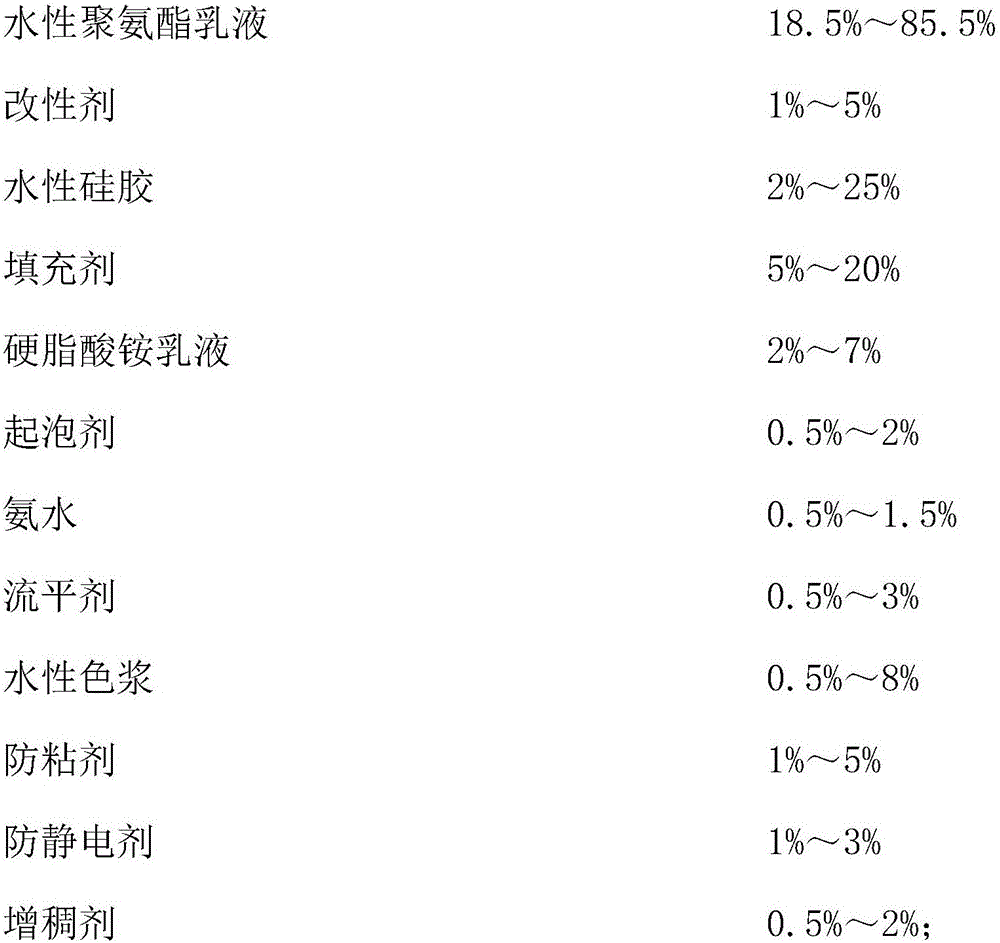

[0037] Prepare the foam coating slurry according to the following ratio:

[0038]

[0039]

[0040] Add the raw materials except the thickener in the prescribed amount in the container one by one, stir evenly with a dispersing mixer, the stirring speed of the dispersing mixer is 1200 rpm, after filtering, add the thickener to adjust the viscosity to 4000apm.s to obtain a foam coating slurry;

[0041] Prepare high-gloss surface treatment agent according to the following ratio:

[0042]

[0043] Add the raw materials except the thickener in the formula amount in sequence in the container, stir evenly with a dispersing mixer, and after filtering, add the thickener to adjust the viscosity to obtain a high-gloss surface treatment agent;

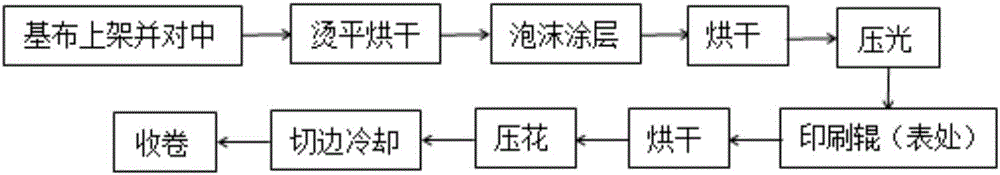

[0044] The leather base cloth is put on the shelf and centered, the leather base cloth is ironed and dried, and the prepared foam coating slurry is made int...

Embodiment 2

[0045] Embodiment 2: imitation leather dull (matte) embossed synthetic leather

[0046] Prepare the foam coating slurry according to the following ratio:

[0047]

[0048]

[0049] Add the formula amount of raw materials except the thickener one by one in the container, and stir evenly with a dispersing mixer. The stirring speed of the dispersing mixer is 1200 rpm. After filtering, add a thickener to adjust the viscosity to 2000apm.s to obtain a foam coating slurry;

[0050] Prepare matting surface treatment agent according to the following ratio:

[0051]

[0052] Add the raw materials except the thickener in the formula amount in sequence in the container, stir evenly with a dispersing mixer, after filtering, add the thickener to adjust the viscosity, and obtain the matting surface treatment agent;

[0053] The leather base cloth is put on the shelf and centered, the leather base cloth is ironed and dried, and the prepared foam coating slurry is made into a coatin...

Embodiment 3

[0055] Embodiment 3: artificial leather high-gloss printing synthetic leather

[0056] Prepare foam coating slurry and high-gloss surface treatment agent with embodiment 1.

[0057] Prepare the rotary screen printing paint according to the following ratio:

[0058]

[0059] The raw materials except the thickener are added in the formula quantity into the container one by one, stirred evenly with a dispersing mixer, and filtered to obtain the rotary screen printing paint.

[0060] The leather base cloth is put on the shelf and centered, the leather base cloth is ironed and dried, and the prepared foam coating slurry is made into a coating foam through an intelligent dynamic foam generator, and then the coating foam is applied to the leather base On the cloth, the amount of coating is precisely controlled by the computer. After the coating is completed, it is dried in an oven to obtain a semi-finished product, and then calendered, rotary screen printed, trimmed and cooled, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com