Industrial production system of active calcium carbonate

An activated calcium carbonate, carbonization tower technology, applied in the direction of calcium carbonate/strontium/barium, calcium/strontium/barium compounds, inorganic chemistry, etc., can solve the lack of product particle size and activity controllable adjustment equipment, lack of production intermediate recovery Equipment, production resources and production cost waste, etc., to improve labor efficiency, reduce emissions, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

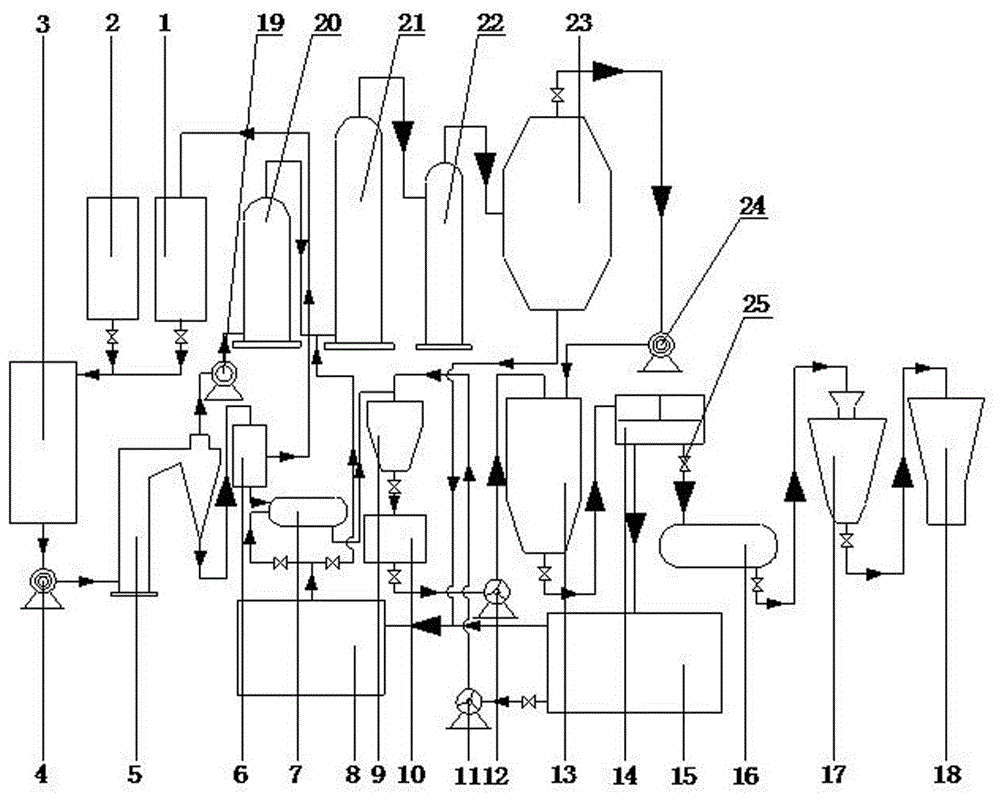

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] like figure 1 A kind of activated calcium carbonate industrial production system shown, comprises limestone silo 1, fuel silo 2, mixing silo 3, calcination tower 5, ash machine 7, carbonization tower 13, centrifuge 14, rotary drying kiln 16, limestone material Bin 1 and fuel bin 2 are connected to mixing bin 3 at the same time, and the outlet of mixing bin 3 is connected to calcining tower 5; the bottom outlet of calcining tower 5 is connected to the inlet of ash machine 7, and the outlet of ash machine 7 is connected to the top of carbonization tower 13 through a pipeline The slurry inlet is connected, the bottom outlet of the carbonization tower 13 is connected to the centrifuge 14, and the bottom outlet of the centrifuge 14 is connected to the rotary drying kiln 16. The production system also includes a screener 6, a hydrocyclone 9, an aging tank 10, an activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com