Tricyclic vacuum arc thruster

A thruster and vacuum arc technology, which is applied to aircrafts, aerospace vehicles, and propulsion system devices of aerospace vehicles, etc., can solve the problems of short thruster life, small cathode ablation area, large plume divergence angle, etc. The effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

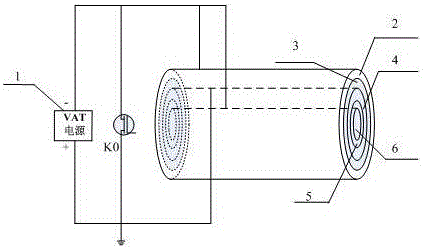

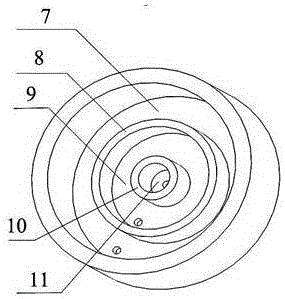

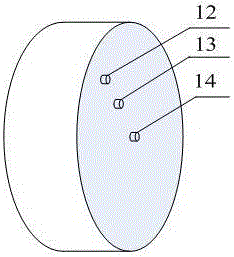

[0012] Embodiment 1, with reference to figure 1 , 2 , 3, a three-ring vacuum arc thruster, the thruster includes a cylindrical cathode 6 placed in the center (the cylindrical cathode structure is conducive to the uniform ablation of the cathode material, thereby prolonging the life of the thruster), the cylindrical cathode 6. The insulator II5, the common anode 4, the insulator I3 and the outer ring cathode 2 are arranged concentrically on the outer periphery in turn; the cylindrical cathode 6, the insulator II5, the common anode 4, the insulator I3 and the outer ring cathode 2 are sequentially installed on the installation base The cylindrical cathode installation groove 11, the insulator II installation seat 10, the common anode installation groove 9, the insulator I installation seat 8 and the outer ring cathode installation groove 7; the cylindrical cathode installation groove 11, the common anode installation groove 9 , Outer ring cathode installation groove 7 three equa...

Embodiment 2

[0013] Embodiment 2. On the basis of Embodiment 1, insulating rings and cathode rings are sequentially added to form a vacuum arc thruster with a multi-ring structure as required, so as to expand the power of the thruster and expand the application range of the thruster.

[0014] When the thruster is working, the voltage peak generated by the power processing unit simultaneously breaks down the metal conductive films on the end faces of the two insulators, and induces the main discharge between the cathode and anode of the two groups. The resulting plasma ions are accelerated by mechanisms such as aerodynamics and electron-ion friction to generate thrust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com