Full-automatic seal stamping machine

A stamping machine, fully automatic technology, applied in printing, stamping and other directions, can solve the problems of inconvenient use, complex structure, manual picking and finishing, etc., saving time, high degree of automation, and enhancing functionality and practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The following is a description of Embodiment 1.

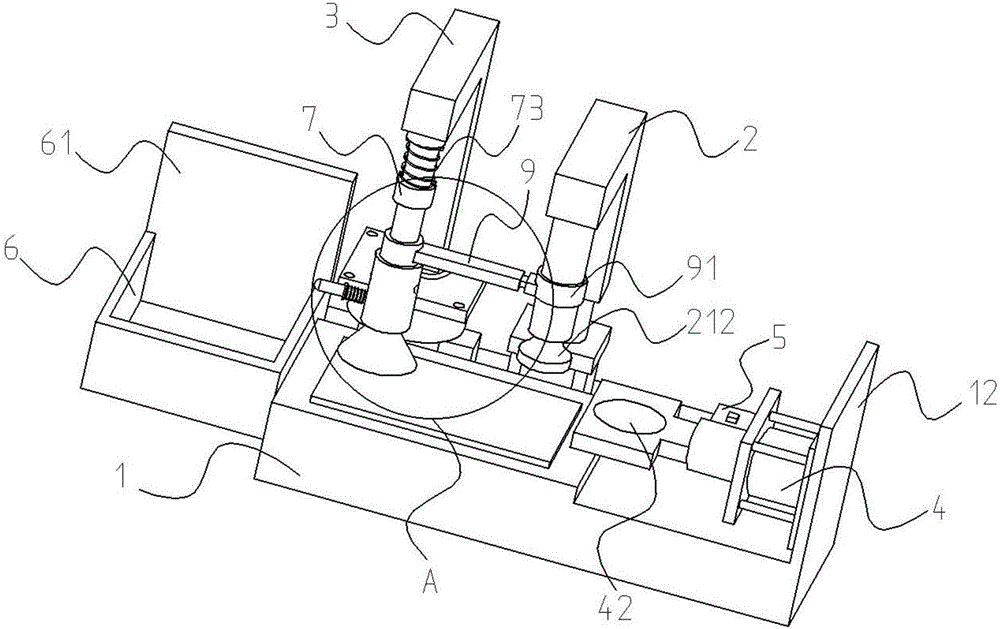

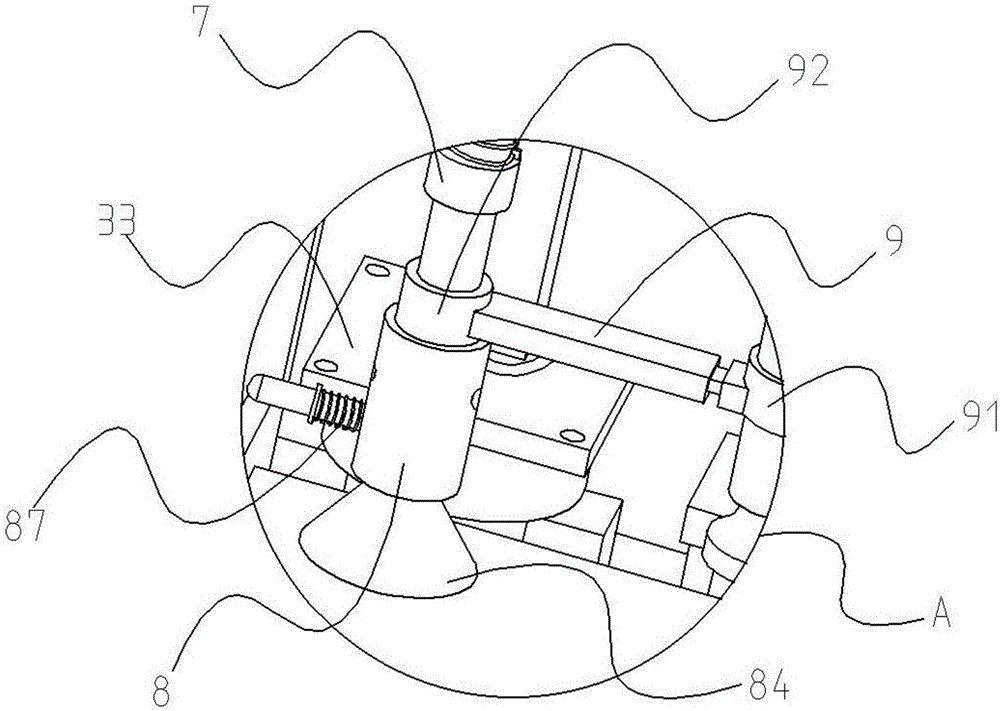

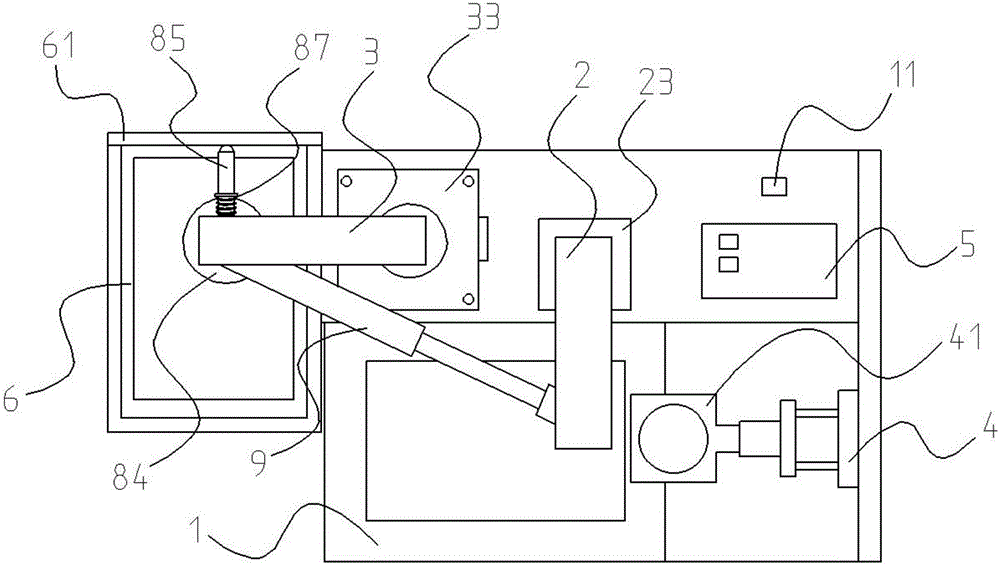

[0046] Such as Figure 1 to Figure 10 As shown, a fully automatic stamping machine includes a workbench 1, a power switch 11, a side plate 12, a lifting arm 2, a lifting rod 21, a positioning groove 211, a seal 212, a pressure sensor 22, a cylinder 23, and a rotary arm 3 , chute body 31, tension spring fixing frame 32, rotary motor 33, cylinder two 4, support body 41, ink pad tank 42, controller 5, storage tank 6, baffle plate 61, connecting body 7, sliding rod 71, pull Spring movable frame 72, extension spring 73, positioning rod 74, mounting body 8, mounting rod 81, piston body 82, track cavity 821, sliding wedge sliding hole 822, piston ball 823, fixed sleeve 83, inner vent hole 831, opening sucker 84. Suction cup opening and closing port 841, suction cup ventilation hole 842, contact pressure rod 85, ring protrusion 851, sliding wedge body 852, outer ventilation hole 86, spring two 87, spring one 88, fixed rod 89, t...

Embodiment 2

[0055] The following is a description of Embodiment 2.

[0056] In Embodiment 2, the same symbols are assigned to the same structures as in the above-mentioned embodiments, and the same descriptions are omitted. Embodiment 2 is improved on the basis of Embodiment 1, and the seal 212 of the device is detachably mounted on the lifting rod 21, and the seal 212 is an automatic ink-filling seal.

[0057] Beneficial effects of the embodiment

[0058] It can greatly improve the efficiency of stamping, and at the same time effectively reduce the labor repetition of adding ink pads and save costs.

[0059] When the device is in use, the workbench 1 is placed on a flat desktop, the document to be stamped is placed on the workbench 1, the power switch 11 is turned on, and the cylinder one 23 starts to lift under the control of the controller 5. Then drive the lifting arm 2 to reciprocate up and down, and then the lifting rod 21 reciprocates up and down, and the seal 212 realizes the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com