Process method and production equipment for automatic hot-pressing folding edge punching of sorting card

A sorting card and punching technology, which is applied to other household appliances, household appliances, household components, etc., to achieve the effect of small temperature deviation, solve the defects of manual operation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with enumerate the embodiment that realizes the present invention.

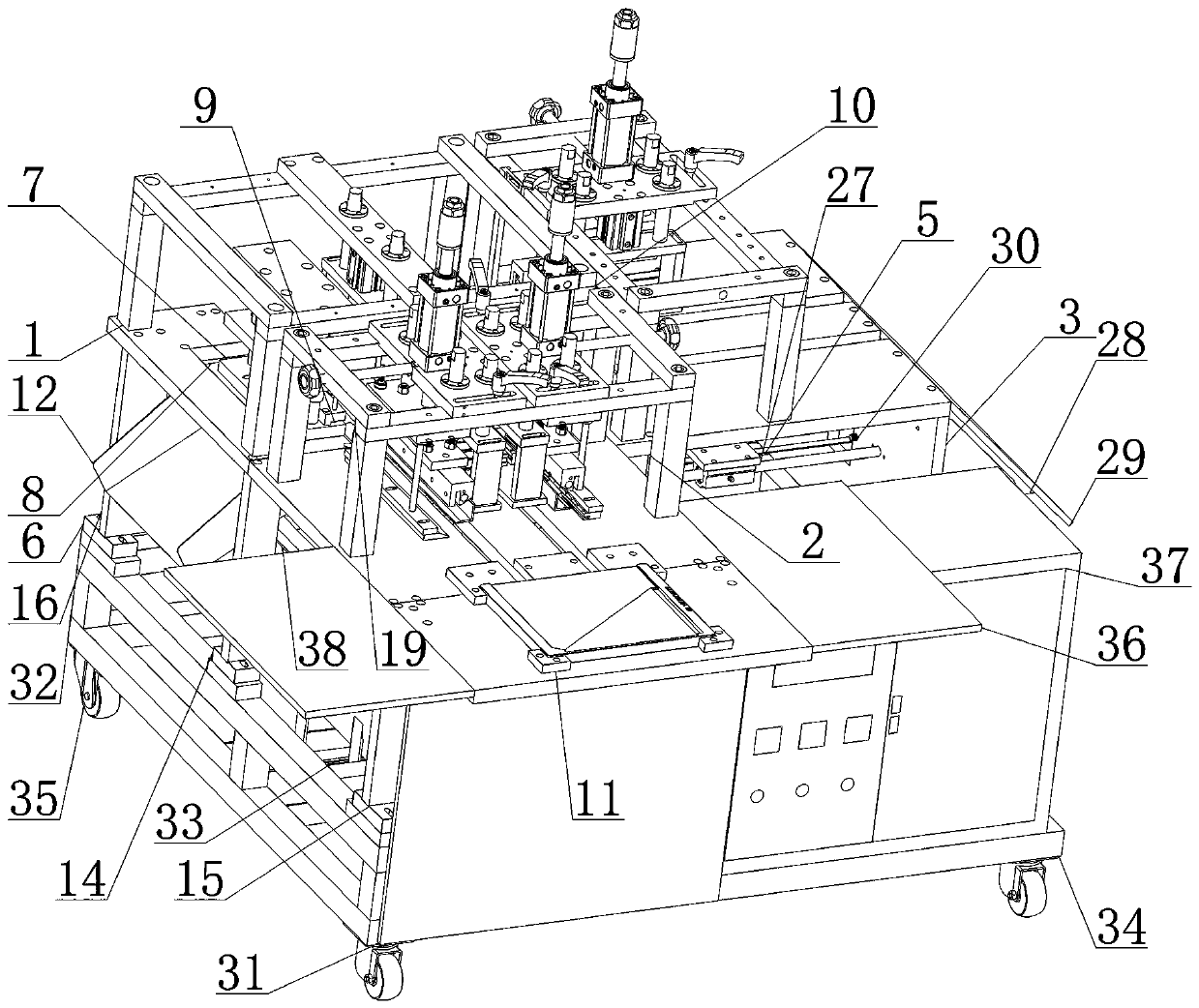

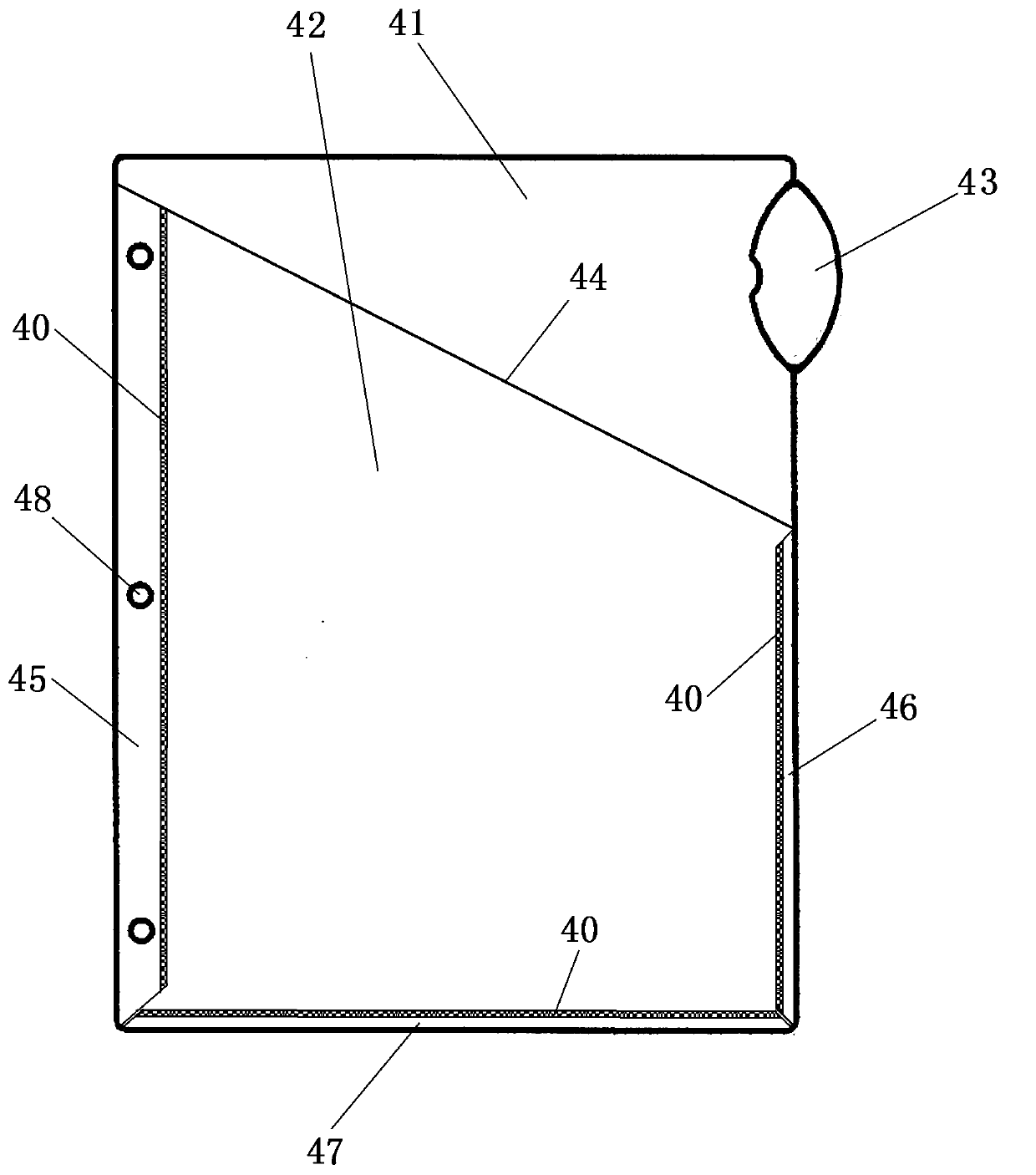

[0027] A process method for automatic hot-pressing folding and punching of classification cards, which is sequentially: matching, folding, hot-pressing, punching, hot-pressing; the difference is: the process steps of automatic hot-pressing folding and punching for:

[0028] (1) Place the pocket sheet on the lower layer of the plate bottom mold, and then place the thick plate on top of the pocket sheet;

[0029] (2) Pedal on the foot switch of the production equipment for automatic hot-pressing folding and punching and turn on the cycle switch, and the equipment will automatically perform the following actions:

[0030] (a) Fold the long and short straight sides first;

[0031] (b) hot pressing the long and short straight sides;

[0032] (c) punching assembly holes;

[0033] (d) Folding the bottom edge;

[0034] (e) hot pressing on the bottom edge;

[0035] (3) Take out the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com