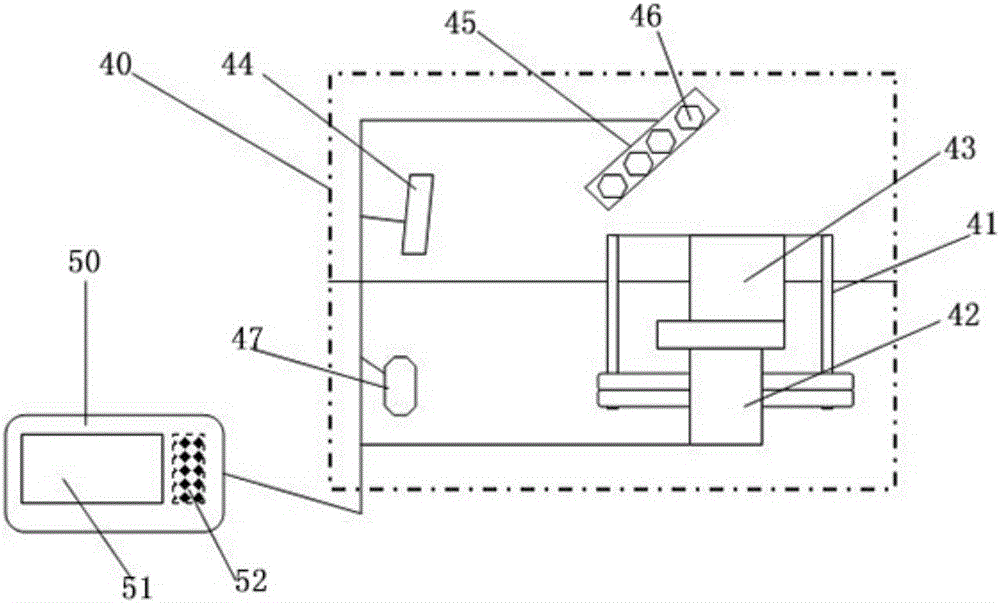

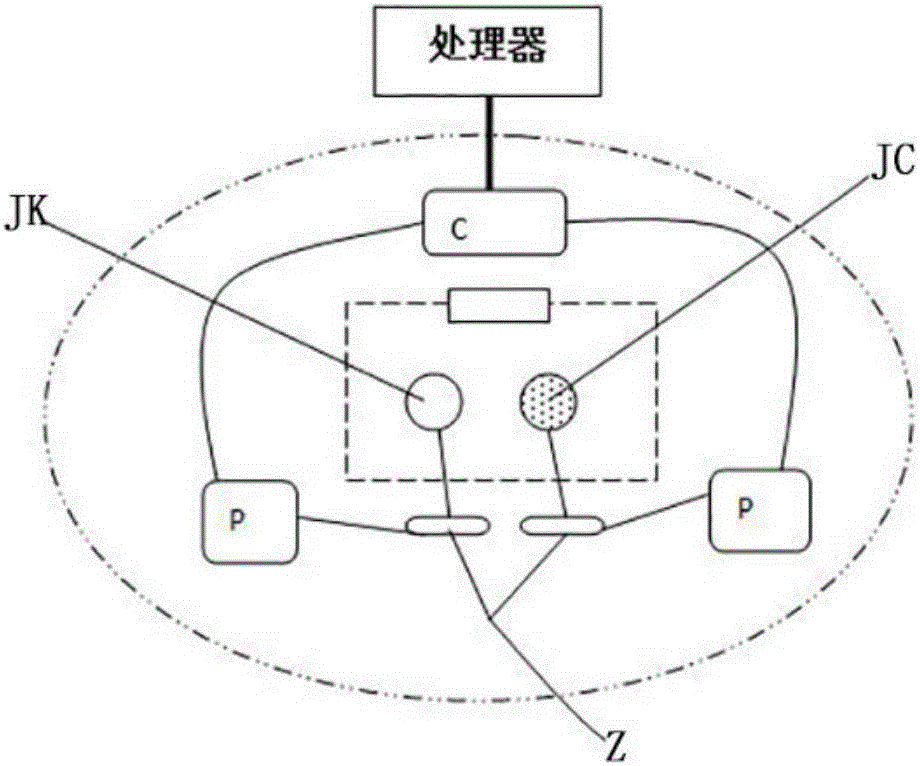

3D printing device capable of monitoring benzene pollutants in real time during printing

A real-time monitoring and 3D printing technology, which can be used in the improvement of process efficiency, processing and manufacturing, and processing data acquisition/processing. The effect of heating and improving the utilization rate of powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0037] The gas sensor using nano-polyaniline-activated carbon as the coating of the gas-sensing material was tested against three gases: methylene chloride, toluene and styrene, and the response speed and limit concentration of the gas sensor to different gases were evaluated, and then the evaluation of this paper was carried out. The embodiment of the invention provides the size of the detection field of the 3D printing device. The comparison between the data of the 3D printing device and the data of the gas chromatography GC method is shown in Table 1 below:

[0038] Table 1 Comparison of 3D printing equipment data and gas chromatography GC monitoring

[0039] Limit concentration (ppm) Response frequency(Hz / ppm) GC(ppm) Chloromethane 0.047 264 0.046 toluene 0.025 238 0.035 Styrene 0.015 305 0.020

[0040] The response frequency of the gas sensor is calculated by the following formula: Δf=3.28×10 -6 ΔM l / V, where ΔM represents the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com