Forging and cogging technique for super-sized aluminum alloy ingots

A technology of casting aluminum alloy ingots and super-large specifications, which is applied in the field of forging and forming. It can solve the problems of complicated process flow, many process control elements, and difficulty in ensuring the forming structure and performance of forgings, so as to improve product qualification rate, improve consistency, The effect of meeting the development needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

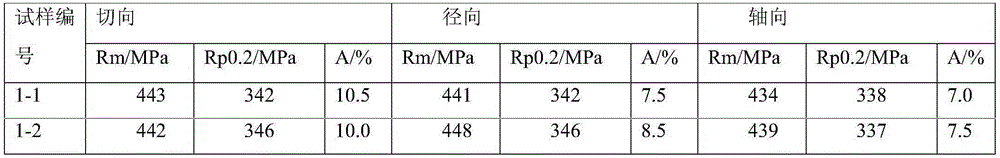

Embodiment 1

[0039] Ingot and tool heating: heat the homogenized Φ1205×2590mm large-diameter 2219 aluminum alloy round ingot and the tools in contact with the ingot during the forging process. Among them, the heating temperature of the ingot is 459°C, and the holding time is 40h; the lower hammer anvil, upsetting plate, punch, mandrel and billet are heated in the same furnace, and the upper hammer anvil, reclaiming tongs, manipulator jaws and other tools are used Fake material preheating.

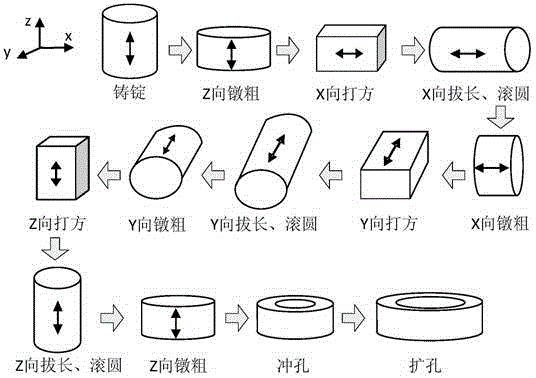

[0040] Multi-directional forging:

[0041] After heating the aluminum alloy round ingot, perform multi-directional forging to obtain a round billet for punching; the specific sequence includes:

[0042] Define the Z direction of the aluminum alloy round ingot as the axial height direction of the aluminum alloy round ingot; the X direction and the Y direction are orthogonal to each other and perpendicular to the Z direction;

[0043] (2.1) Z-direction upsetting: upsetting the ingot along the Z-directio...

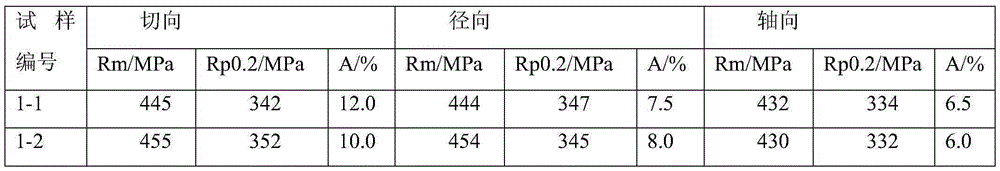

Embodiment 2

[0067] Ingot and tool heating: heat the homogenized Φ1260×2890mm large-diameter 2219 aluminum alloy round ingot and the tools in contact with the ingot during the forging process. Among them, the heating temperature of the ingot is 462°C, and the holding time is 41 hours; the lower hammer anvil, upsetting plate, punch, mandrel and billet are heated in the same furnace, and the upper hammer anvil, reclaiming tongs, manipulator jaws and other tools are used Fake material preheating.

[0068] Multi-directional forging:

[0069] After heating the aluminum alloy round ingot, perform multi-directional forging to obtain a round billet for punching; the specific sequence includes:

[0070] Define the Z direction of the aluminum alloy round ingot as the axial height direction of the aluminum alloy round ingot; the X direction and the Y direction are orthogonal to each other and perpendicular to the Z direction;

[0071] (2.1) Z-direction upsetting: upsetting the ingot along the Z-dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com