cleaning system

A cleaning system and cleaning box technology, applied in the field of cleaning systems, can solve the problems of poor cleaning effect, low efficiency of grinding film, difficulty in completely removing grinding powder of grinding film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

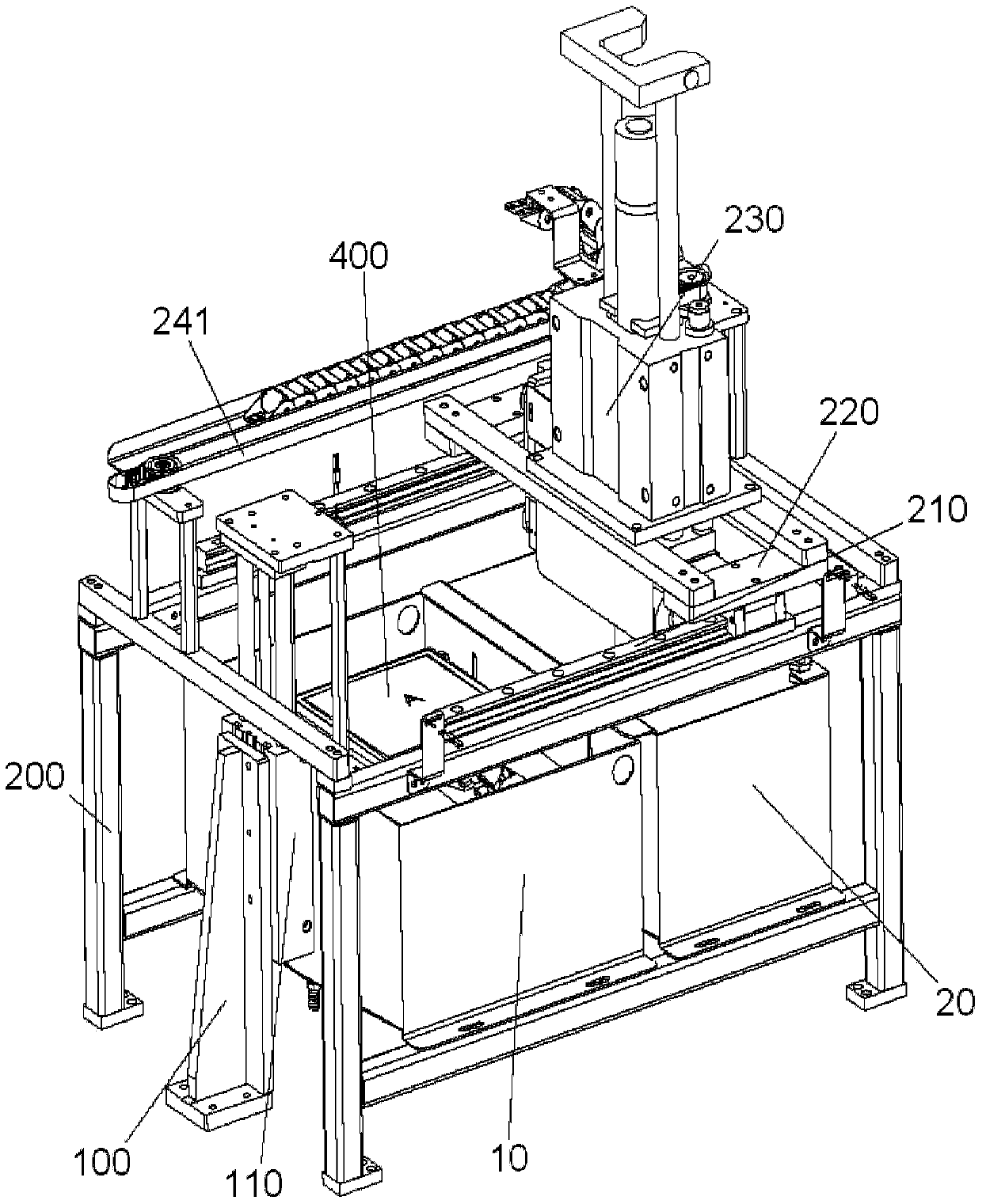

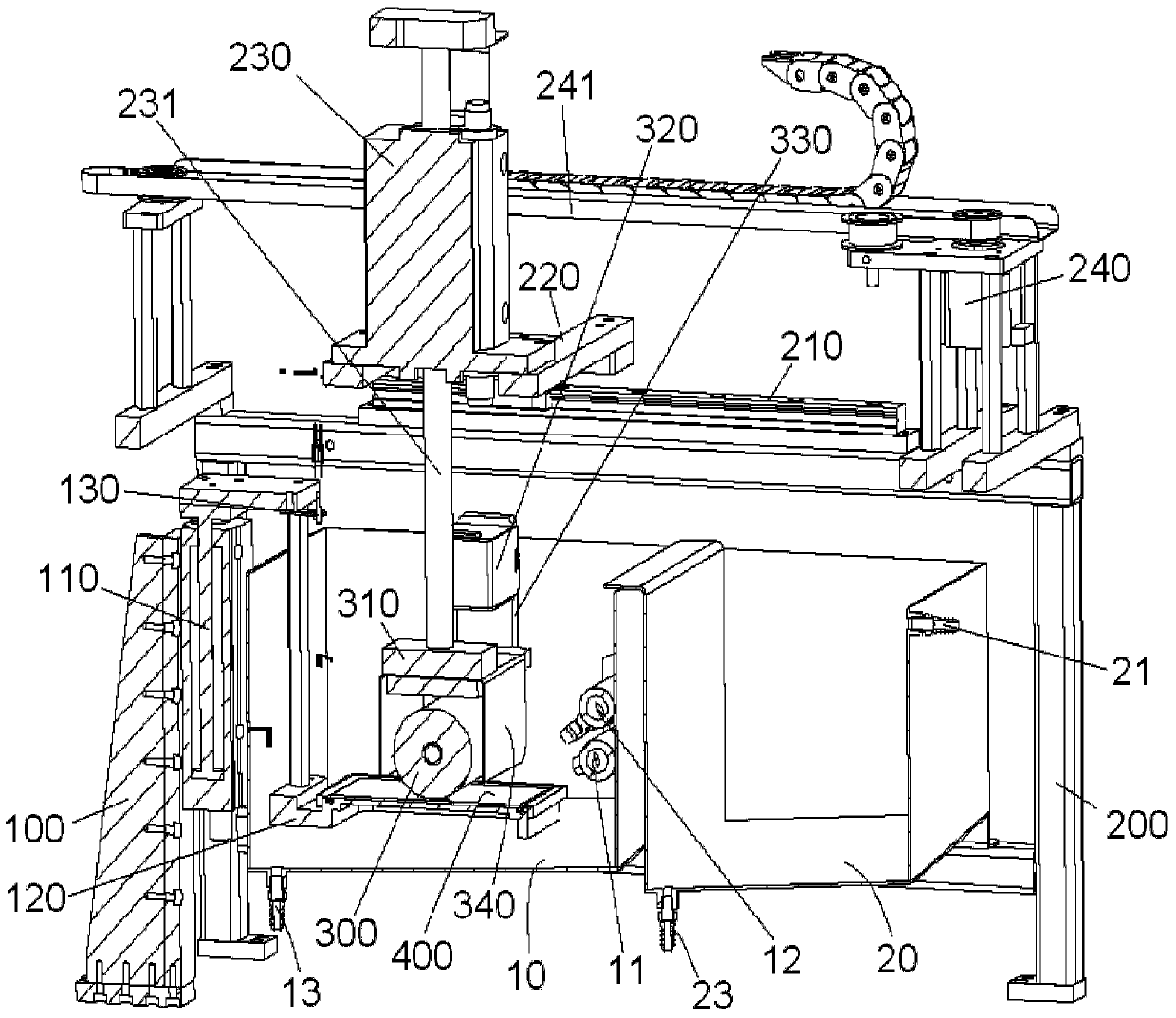

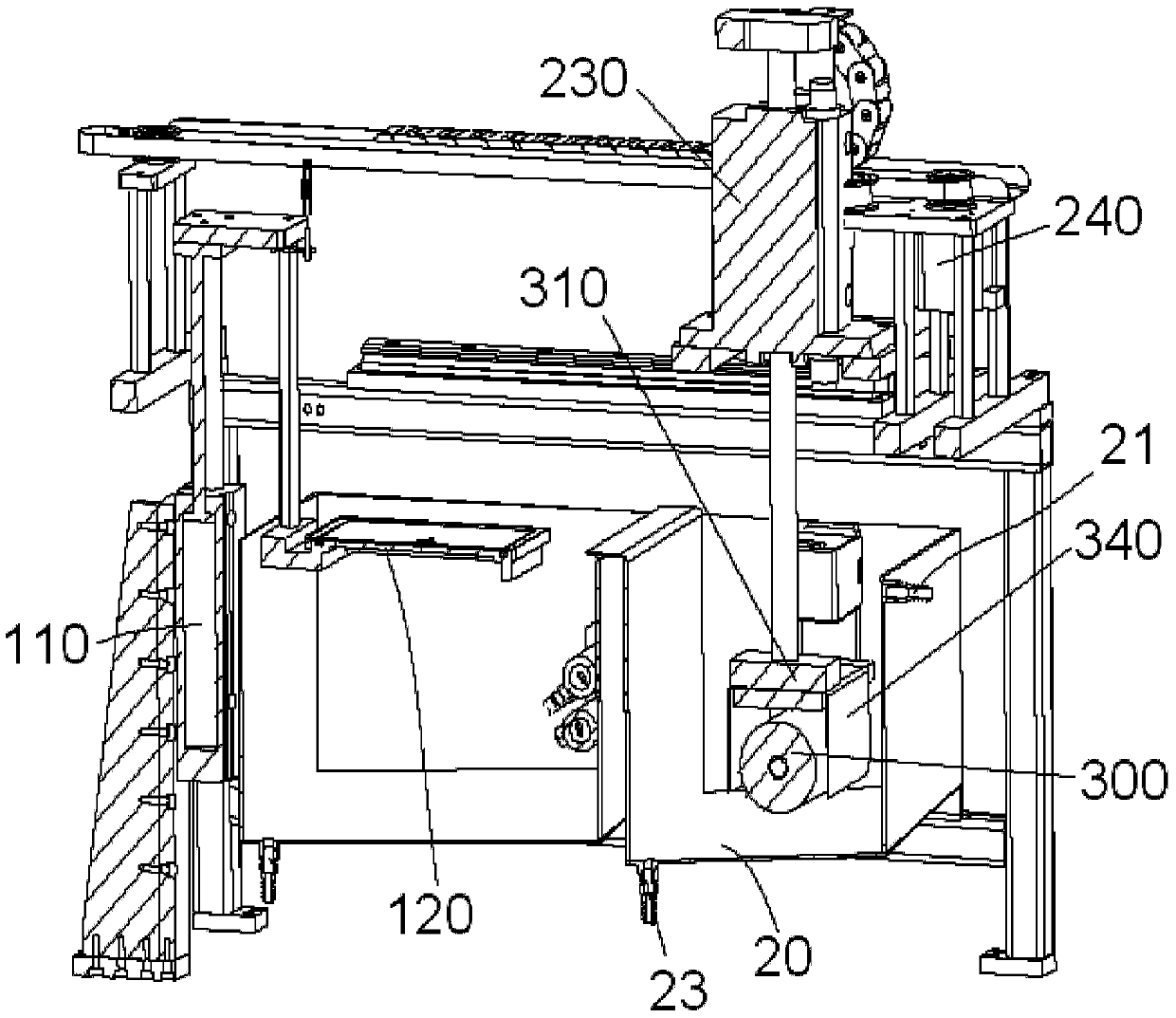

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0029] According to a general technical concept of the present invention, a cleaning system is provided, comprising: a first cleaning box; a grinding film carrying and moving unit, adapted to move the grinding film to be cleaned into the first cleaning box and keep it in the first cleaning box. In the first cleaning tank; the first cleaning liquid spray head is suitable for spraying cleaning liquid to the grinding film held in the first cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com