A micro pyrotechnic discharge system

A technology of ignition head and lead wire, which is used in fireworks, offensive equipment, weapon types, etc., can solve the problem of cumbersome installation and use of connecting components of ignition head and quick lead wire, difficult to meet the practical needs of micro-fireworks discharge operation, and short service life, etc. problems, to achieve the effect of reduced labor load and mental tension, firm and reliable connection, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] see Figure 10 , reflecting a specific structure of the present invention, the micro-firework discharge system includes a control host 501, a connecting main cable 502, a terminal block 503, a wire 504 and a connection unit, and the connection unit includes an ignition head and a connector 505 And the quick lead 401 that connects the firework 506.

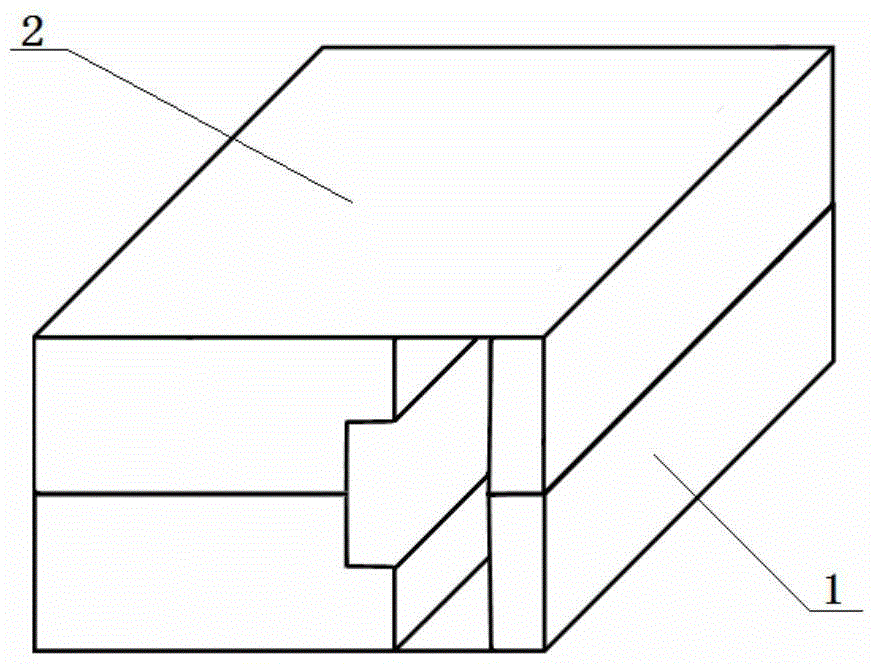

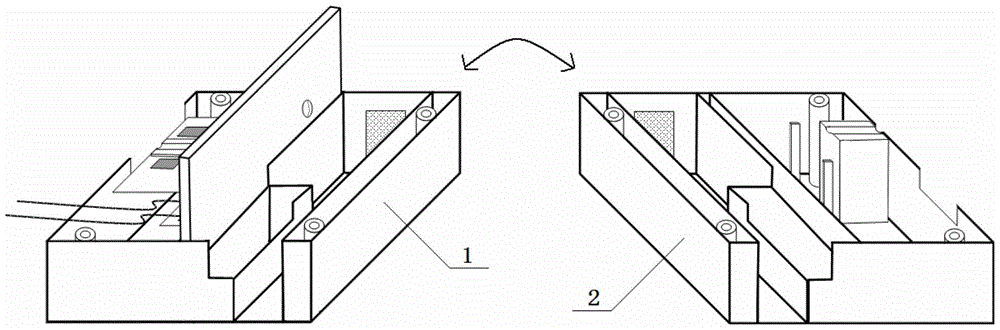

[0024] see figure 1 , 2 , the connector is a box body, which is composed of a corresponding upper half box body 2 and a lower half box body 1, and the two are connected through bolt holes 109:

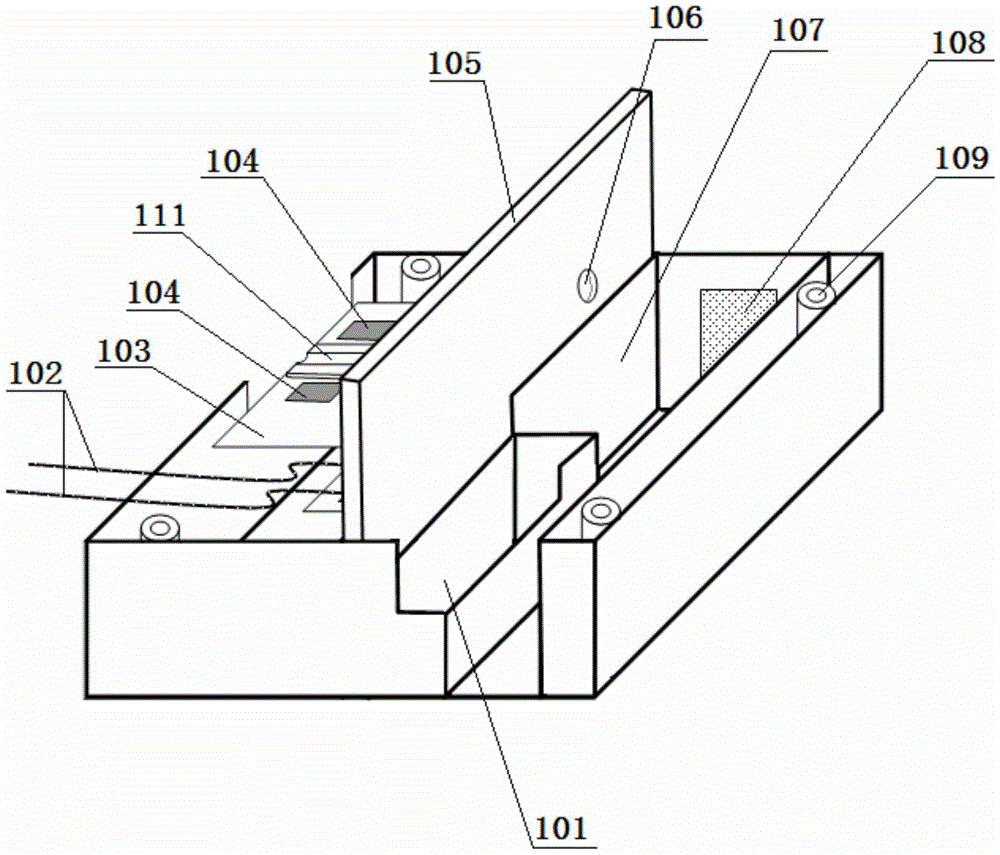

[0025] like image 3 , 4 As shown, in the lower half of the box body 1: the two adjacent sides of the box body are respectively provided with an ignition head insertion port and a quick lead insertion port, and the interior of the box body is correspondingly divided into an ignition head insertion cavity and a quick lead insertion cavity 107 . The fireproof film 105 is separated between the ignition head insertion chamber and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com