Floor connecting structure

A floor and body technology, applied in the direction of building structure, floor, building, etc., can solve the problems of complicated floor connection and unreliable connection, and achieve the effect of simple connection, firm and reliable connection, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

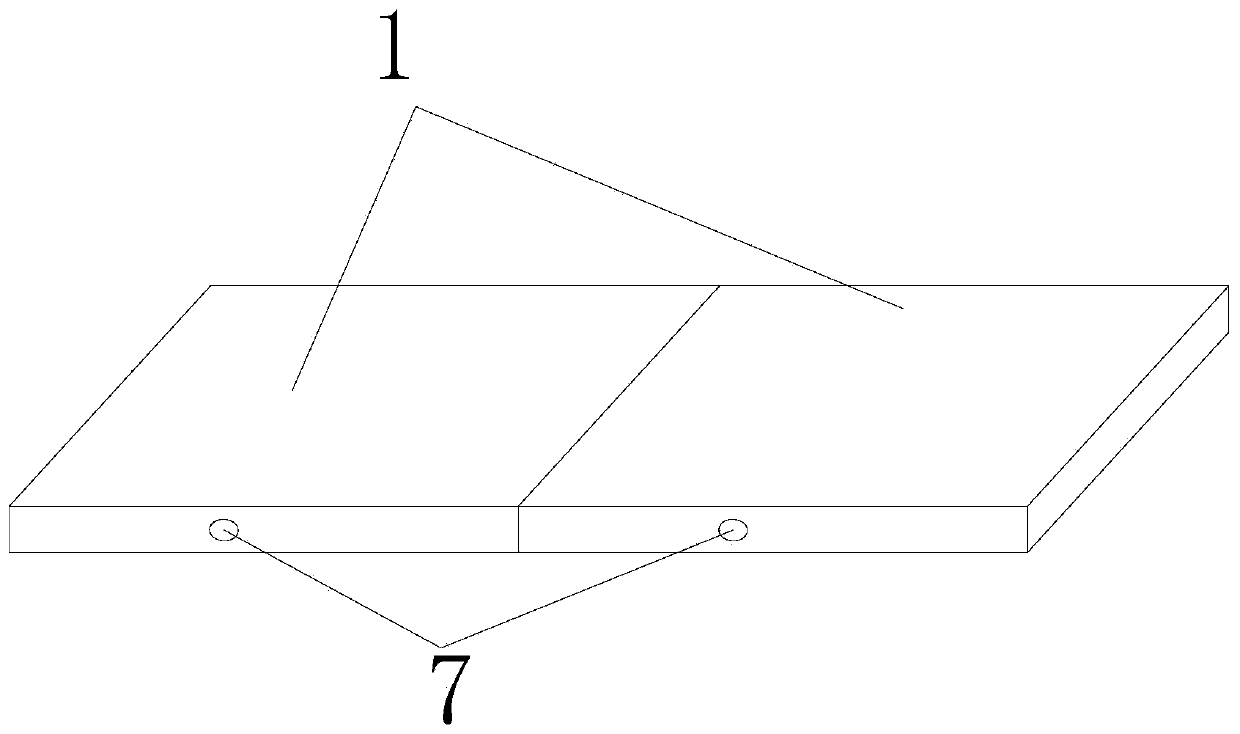

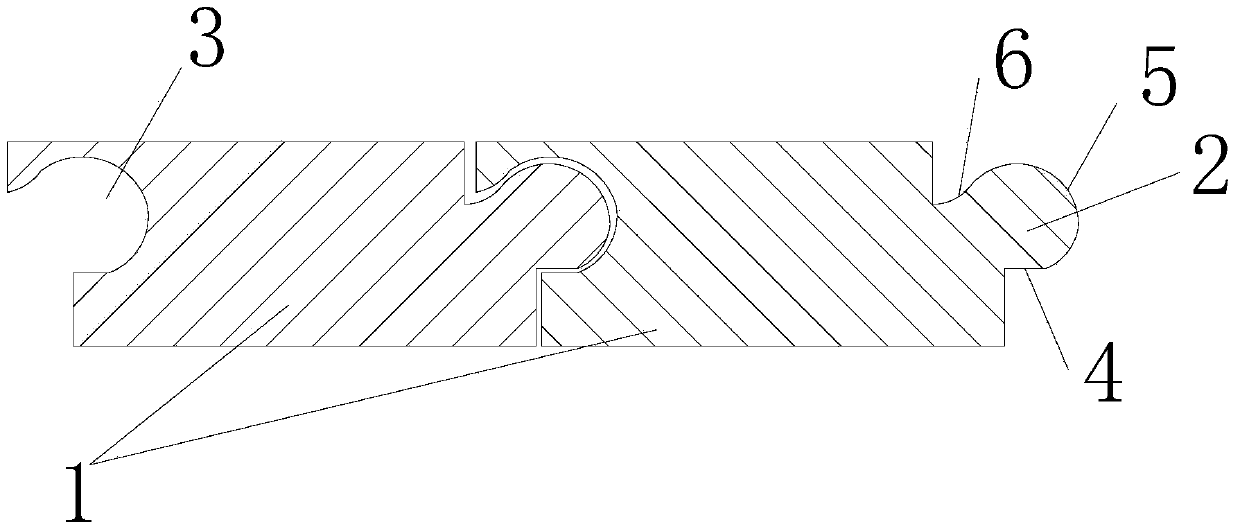

[0014] figure 1 It is a structural schematic diagram of an embodiment of the present invention; figure 2 yes figure 1 cutaway view.

[0015] Such as figure 1 and figure 2 As shown, a preferred floor joint structure of the present invention includes: a floor body 1, the two ends of the floor body 1 in the width direction are respectively provided with an engagement protrusion 2 and an engagement groove 3, and the engagement protrusion 2 and the engagement groove 3 The shapes of the floor plates are matched with each other, and the joint of the floor is realized through the cooperation of the joint protrusion 2 and the joint groove 3 .

[0016] The engaging protrusion 2 includes a reference segment 4 , a positioning segment 5 and an anti-slip segment 6 .

[0017] Specifically, the reference section 4 is located at the lower end of the floor body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com