Positioning and coupling structure of suspension and trailer axle

A technology for connecting structures and axles, which is applied to suspensions, vehicle parts, cantilevers mounted on pivots, etc., can solve the problems of affecting driving stability, easy looseness, and small deformation, so as not to weaken the strength of the axle body , The connection is firm and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

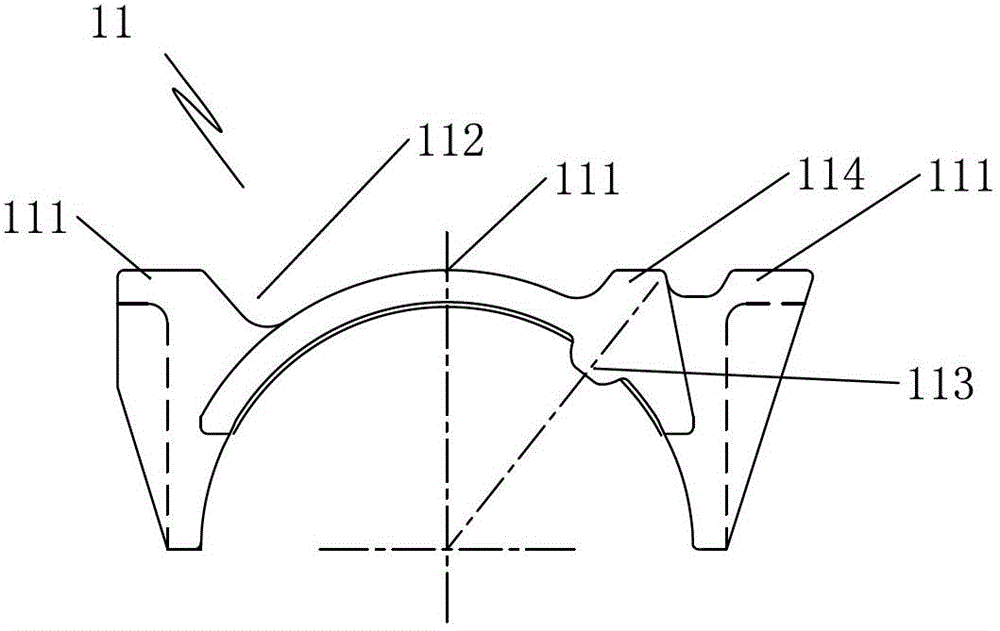

[0020] like Figures 1 to 4 As shown, the suspension and trailer axle positioning coupling structure of the present invention includes a suspension system 1, an axle 2 and a connecting piece for locking the axle 2 and the suspension system 1, specifically, the connecting piece is a U-shaped bolt 3. The suspension system 1 includes a base plate 13, a side support plate 12 and an axle seat 11, and the specific structure is as follows:

[0021] The shaft seat 11 is welded and fixed on the side support plate 12 by setting several support platforms 111 , and there are compression deformation chambers 112 between adjacent support platforms 111 . The axle base 11 is provided with a positioning projection 113 on one side of the vertical central axis A of the axle 2 , and the position of the axle 2 corresponding to the positioning projection 113 is provided with a positioning groove that cooperates with the positioning projection 113 . 21. The included angle α between the radial cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com