Vehicle engine fuel injection nozzle and combustion chamber carbon cleaning device

A technology for automobile engine and cleaning device, which is applied to engine components, fuel injection device, engine testing and other directions, can solve the problems of long time, inappropriateness, trouble, etc., and achieve the effect of improving effect, saving manpower and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

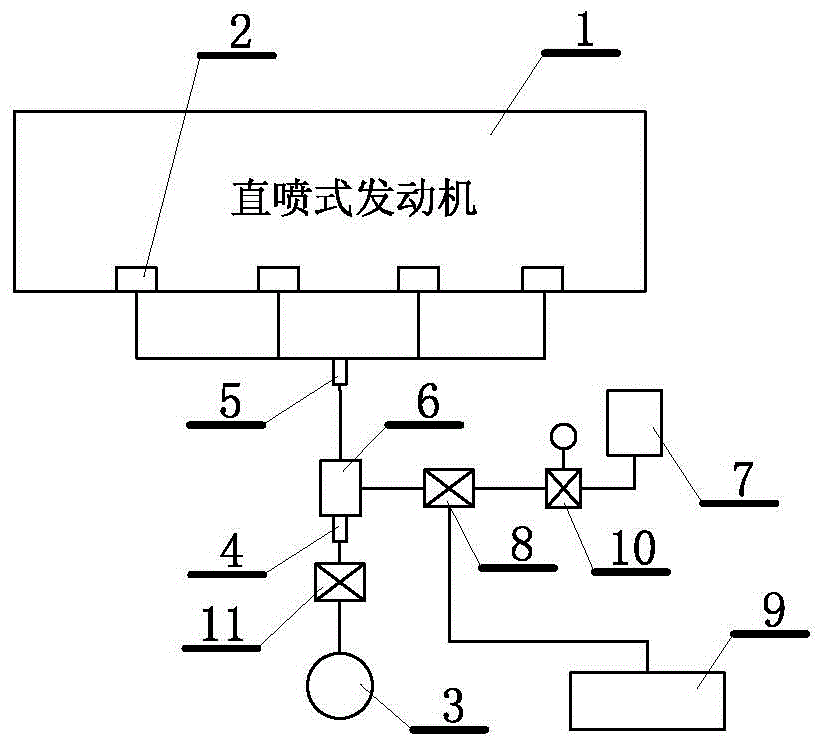

Embodiment 1

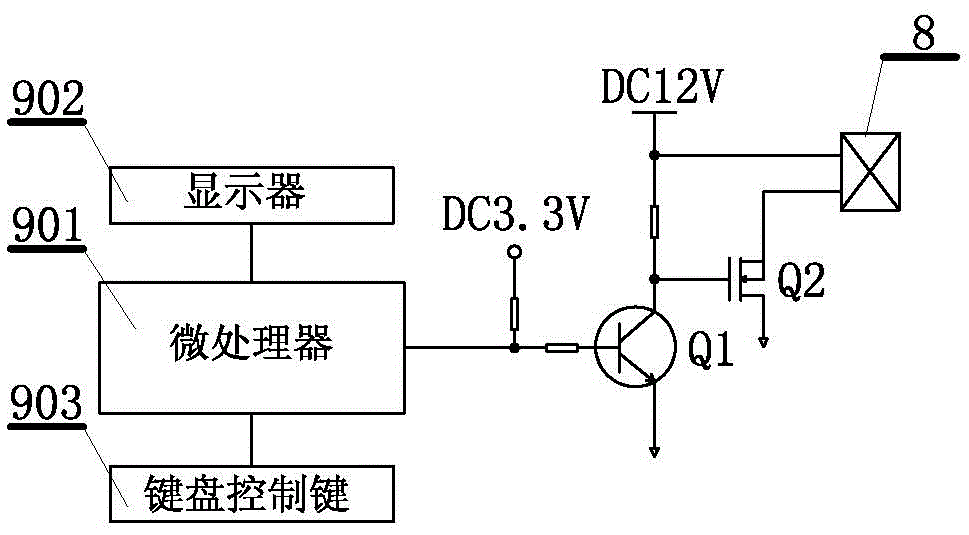

[0022] An automobile engine fuel injector and a combustion chamber decarbonization cleaning device, especially suitable for direct injection engines, including an automobile engine 1, an oil injector 2 for supplying cylinders on the engine, the fuel supply of the fuel injector is delivered by an oil pump 3 After the fuel is extracted from the fuel tank, it is supplied after being connected to the oil circuit interface 5 in front of the engine fuel injector through a fuel supply pipeline provided with a quick joint 4, wherein, when the engine fuel injector needs to be cleaned, the quick A tee joint 6 is connected between the joint and the oil circuit interface. The first inlet of the tee joint is provided with the same buckle as that of the oil circuit interface so as to be connected with the quick joint. The quick joint is connected to the first entrance of the three-way joint. The outlet connection of the three-way joint is provided with the same quick joint as the fuel supply...

Embodiment 2

[0029]A control method based on the automobile engine fuel injector of embodiment 1 and the carbon removal and cleaning control device of the combustion chamber; therefore, the content of 1 in the embodiment should be regarded as the content in the present embodiment, and the method includes preparatory steps and a cleaning step where:

[0030] The preparatory steps are: shut down the engine, disconnect the oil circuit interface before the engine fuel injection nozzle, connect the output port of a three-way joint to the oil circuit interface and communicate with the engine fuel injection nozzle, and an input port of the three-way joint Connect to the second pressure regulating valve, the input port of the second pressure regulating valve is connected to the disconnected oil supply pipe connected to the oil circuit interface, and the other input port of the three-way joint is connected to an electronically controlled cleaning agent nozzle , the liquid inlet of the electronicall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com