Reaction kettle cleaning machine

A technology for reactor cleaning and head cleaning, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc. It can solve the problems of aggravating corrosion of reactor equipment, reducing heat transfer performance, increasing reaction time, etc., and achieves mobile Easy to control, satisfactory cleaning, and scientific structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

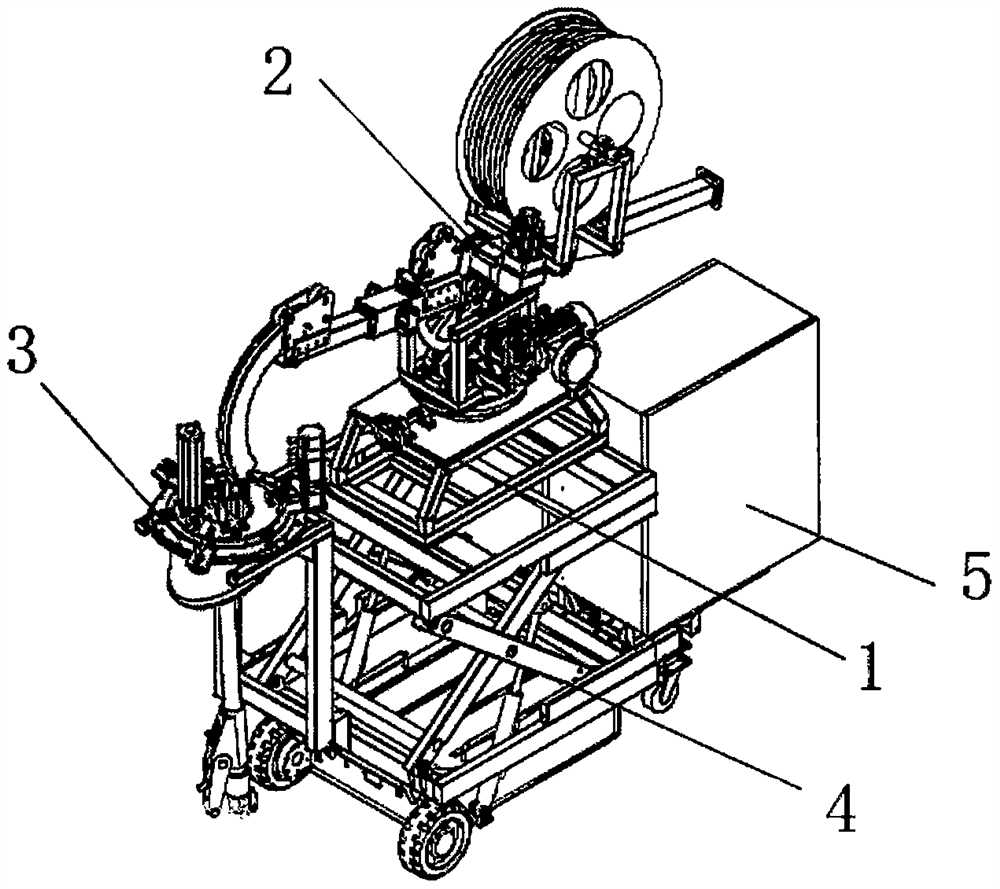

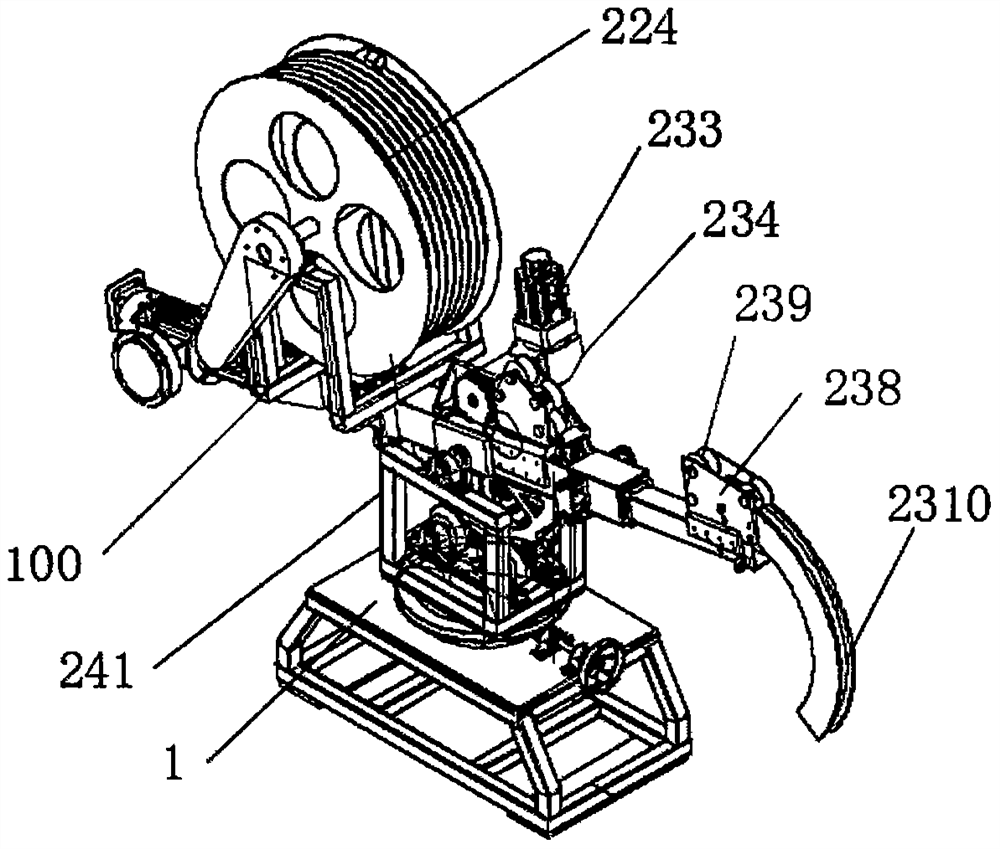

[0028] Such as Figure 1 to Figure 6 As shown, a reactor cleaning machine 100 includes: a frame 1, a control system 2, and an actuator 3; the control system is arranged on the frame, and the actuator is located in front of the control system;

[0029] The frame 1 is shaped like a coffee table and is a solid steel structure.

[0030] The control system 2 includes a rotating mechanism 21, a high-pressure water pipe retracting mechanism 22, a telescoping mechanism 23, and a pitching mechanism 24; There are balls, which are controlled by the hand crank mechanism 212. The hand crank mechanism is composed of a handle, a hand wheel, a rocker, and a rocker seat. Gears are installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com