Non-contact type dynamic power supply system coil for trains in rail transit

A rail transit train, non-contact technology, applied in circuits, inductors, motor vehicles, etc., can solve problems such as unfavorable system parameter design, affecting system efficiency, etc., to reduce reactive power output, stabilize the coupling coefficient, and improve the system. The effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

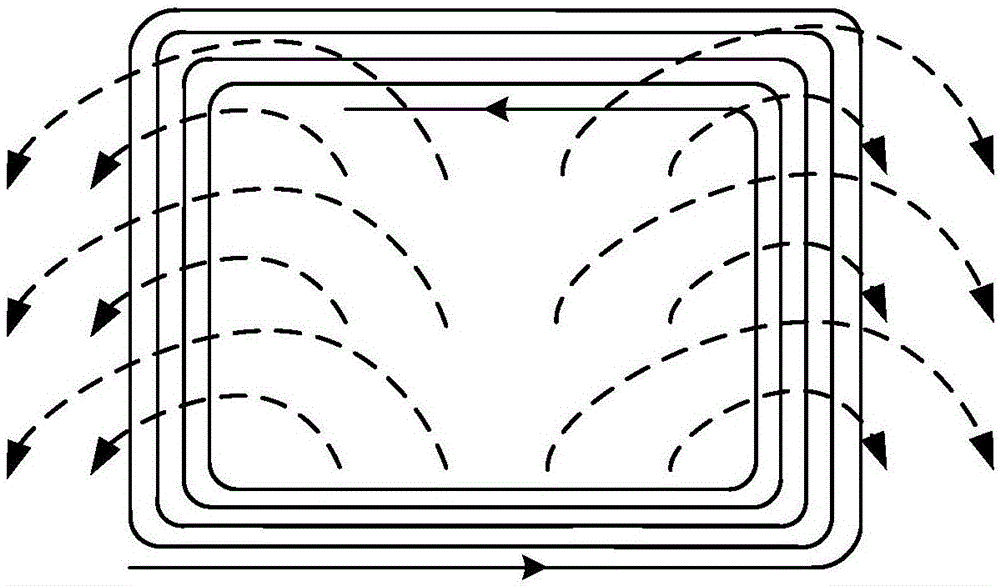

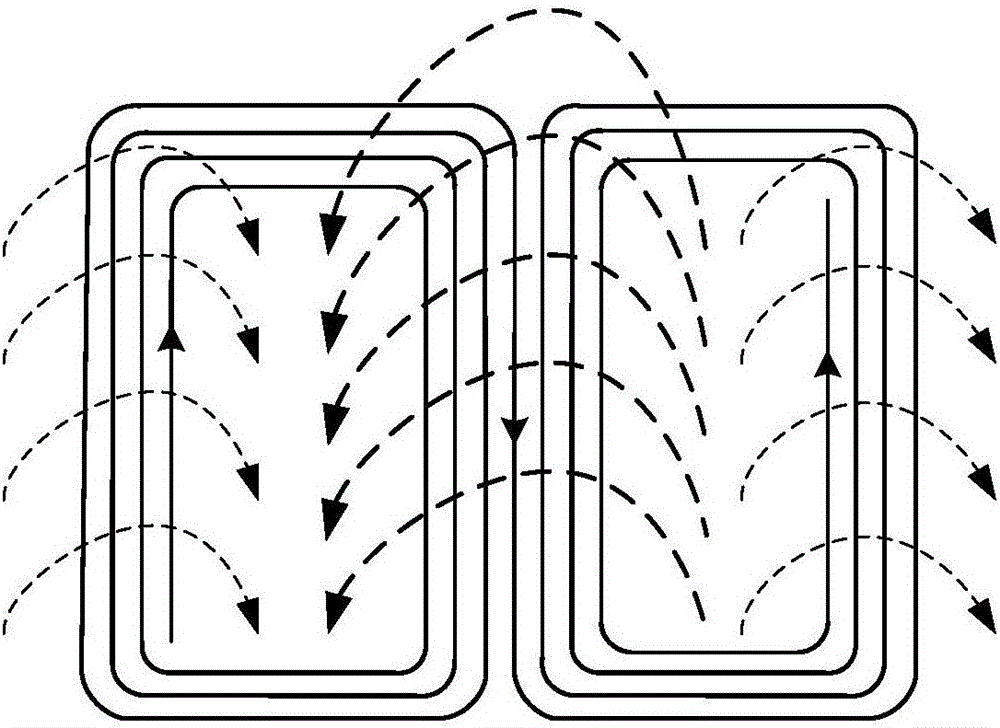

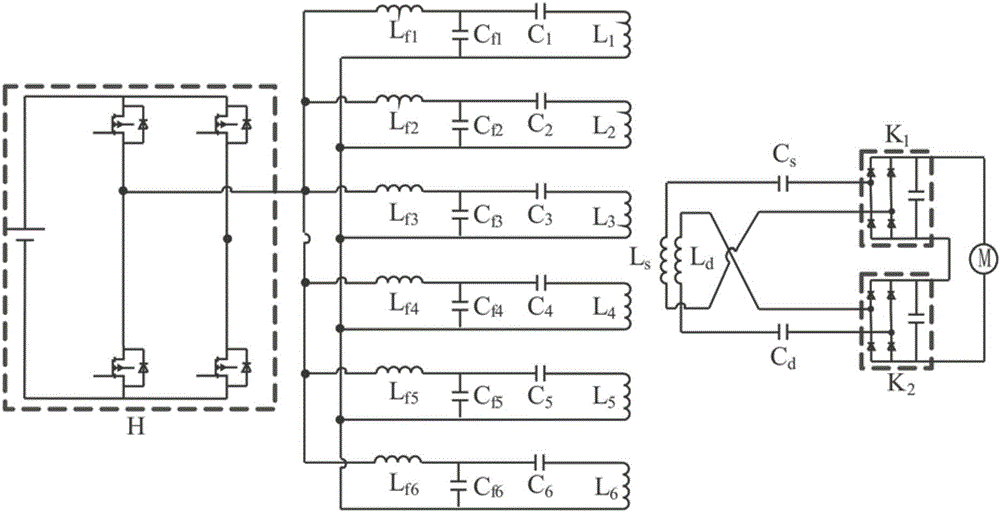

[0022] The technical solutions and technical effects of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. A non-contact dynamic power supply system coil for a rail transit train, including an energy transmitting coil laid along the track and an energy pickup coil installed at the bottom of the train. The coil is connected to the bipolar coil on the transmitting side, and the direction of the main magnetic field generated by the bipolar coil on the transmitting side is perpendicular to the forward direction of the train. The compensation filter circuits where each energy transmitting coil is located are connected in parallel to the high-frequency AC power supply H; the energy pickup coil includes a long One pickup-side unipolar coil and one pickup-side bipolar coil with the same width as the energy transmitting coil, the pickup-side unipolar coil is connected in series with the compensation cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com