Full-modal-waveguide-structure-based substrate-integrated waveguide directional coupler

A substrate-integrated waveguide and directional coupler technology, which is applied in waveguide devices, electrical components, connecting devices, etc., can solve the problems of large lateral size and unfavorable device miniaturization design, and achieve good broadband performance and excellent miniaturization performance , good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

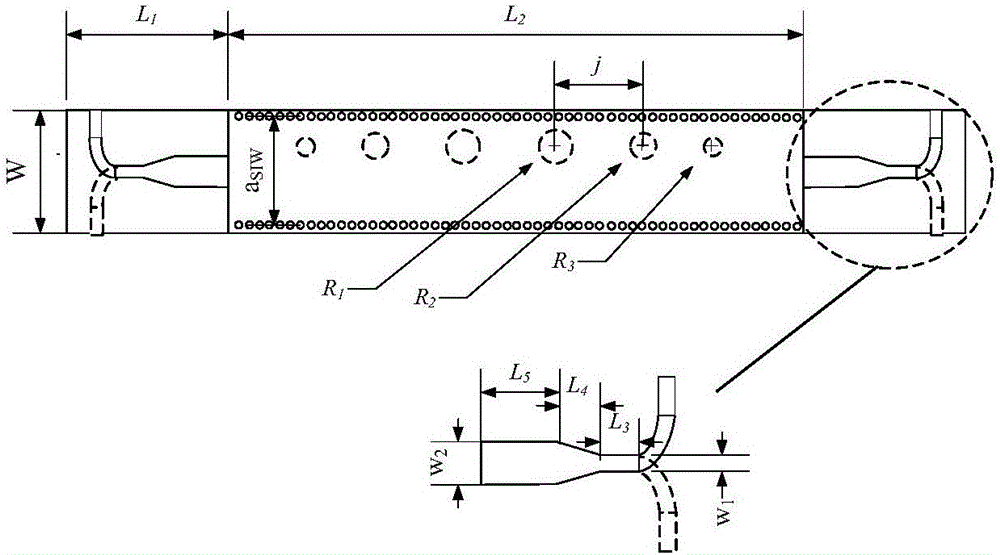

[0024] figure 1 It is a schematic diagram of the structure of the upper metal layer of the directional coupler of the present invention. Such as figure 1 As shown in the structure, the substrate-integrated waveguide directional coupler based on the full-mode waveguide structure is composed of a double-layer dielectric substrate and a printing structure of upper, middle and lower layers, wherein the double-layer dielectric substrate is formed by superimposing the broadside; specifically, The substrate-integrated waveguide directional coupler based on the full-mode waveguide structure includes a first layer of dielectric substrate, a second layer of dielectric substrate and ports; the upper surface of the first layer of dielectric substrate is provided with an upper metal layer, and the first layer of dielectric The lower surface of the substrate is provided with a coupling metal layer; the upper metal layer includes the upper metal layer feed structure and the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com