Quality control method for mass LED packaging production process

A technology for LED packaging and production process, applied in the field of intelligent analysis, which can solve problems such as being susceptible to interference and complex physical models, and achieve the effects of adjustment, failure prevention, and generalization ability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

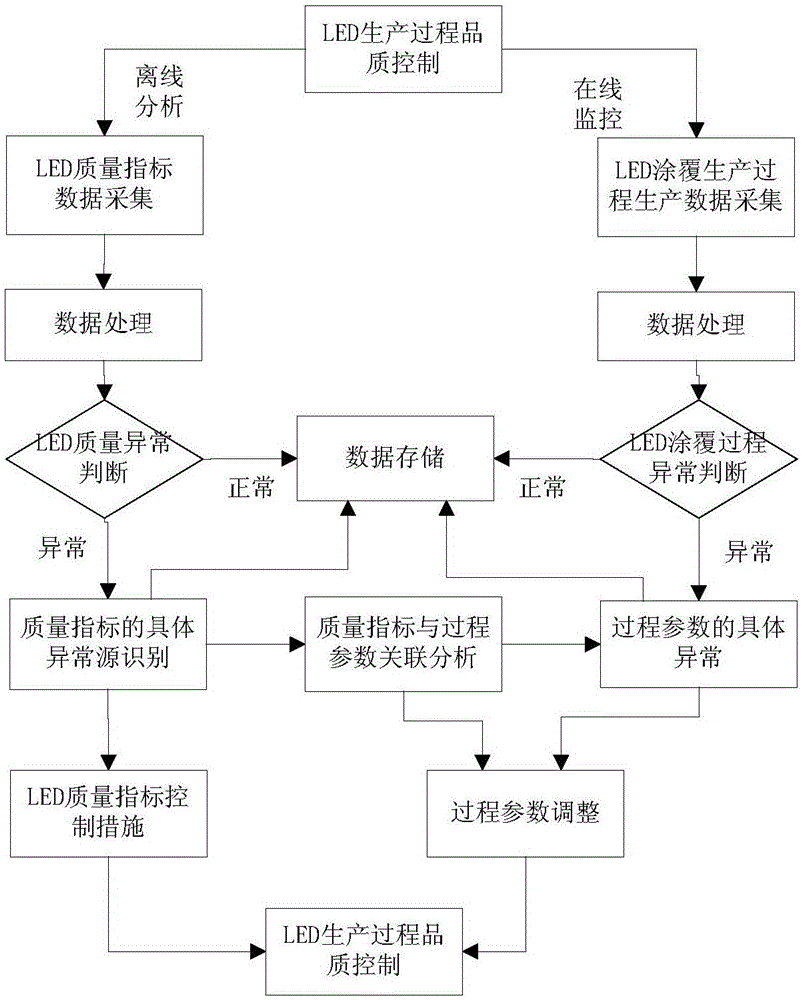

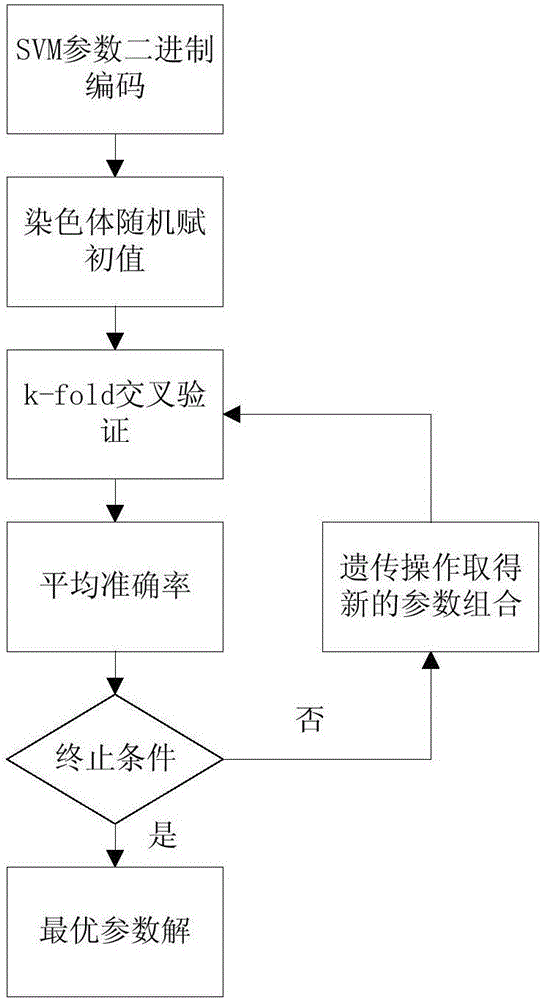

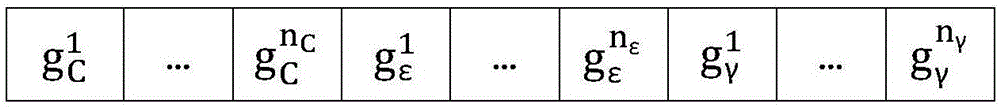

[0034] The invention provides a quality control method in the production process of mass LED encapsulation, such as figure 1 As shown, this example includes an offline analysis module for LED products and an online monitoring module for the LED coating production process. The LED product offline analysis module collects LED quality parameter data, and uses multivariate control charts to identify abnormal states; for abnormal states, an optimized support vector machine is used to identify abnormal sources, determine abnormal quality indicators, and analyze its associated abnormal production parameters. Take quality control measures or adjust process parameters. The online monitoring module of the LED coating process collects the production process parameter data, and uses the multivariable control chart to identify the abnormal state of the production process; for the abnormal state, the optimized support vector machine method is used to identify the source of the abnormality, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com