Device and method for on-line inspection of water content of surface of band

A strip surface and strip technology, which is applied in the direction of measuring devices, mechanical devices, and material analysis, can solve the problems of inability to evaluate the water content of the strip surface in time, the inability to judge the risk of strip washing corrosion, and the batch size of the strip surface. Corrosion coils and other problems, to achieve stable and effective measurement results, simple and effective detection methods, and more damaged layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In this embodiment, the detection handle 3 is an aluminum handle with a yield strength of 130-240 mpa, a thickness of 1.5-2.0 mm, and a length of 250 mm.

[0025] In this embodiment, the cushion block 4 is a plastic foam board.

[0026] In this embodiment, the fixed rope 2 is a rubber band.

[0027] A method for online inspection of strip surface moisture, comprising the following steps:

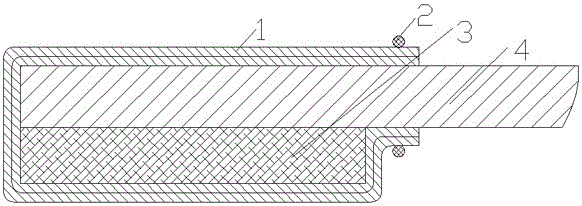

[0028] (1) Make the testing tool: First, take the testing paper 1 and fold it to make 2~6 layers. The external dimensions are required to be 20~50mm wide and 20~120mm long. A cushion block 4, then wrap the folded detection paper 1 around the test end of the detection handle, and then use a fixed rope 4 to bind the detection paper 1 and the detection handle 3;

[0029] (2) Detection: hold the holding end of the detection handle 3, press the test end of the detection handle 3 against the surface of the running strip on the production line, and after the contact length between th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com