scroll compressor

A scroll compressor and rotating shaft technology, applied in the field of scroll compressors, can solve the problems of reduced space utilization, increased vibration and noise of the compressor, and longer axial length of the compressor, so as to reduce discharge loss and compression Loss, the effect of improving compressor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

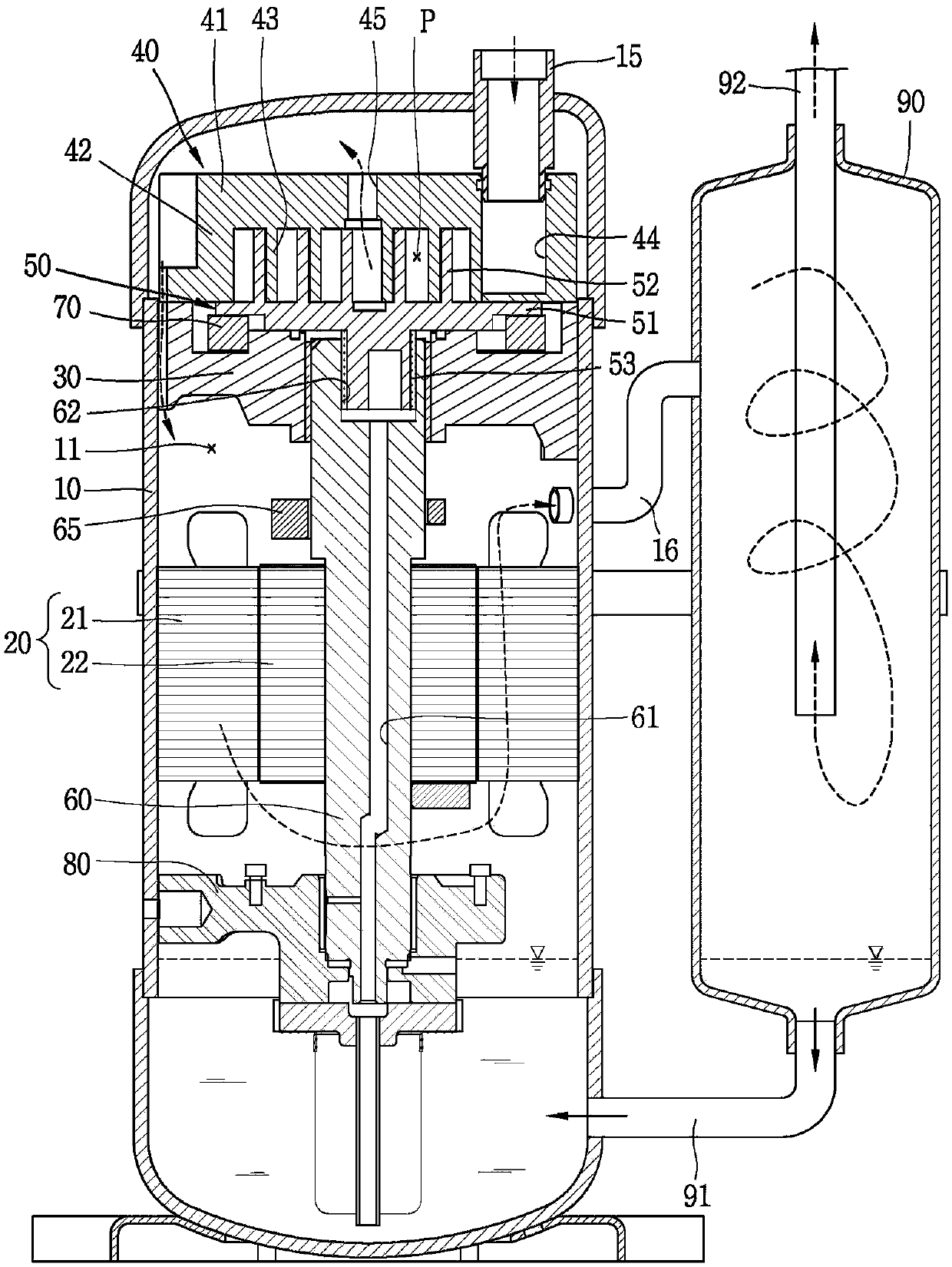

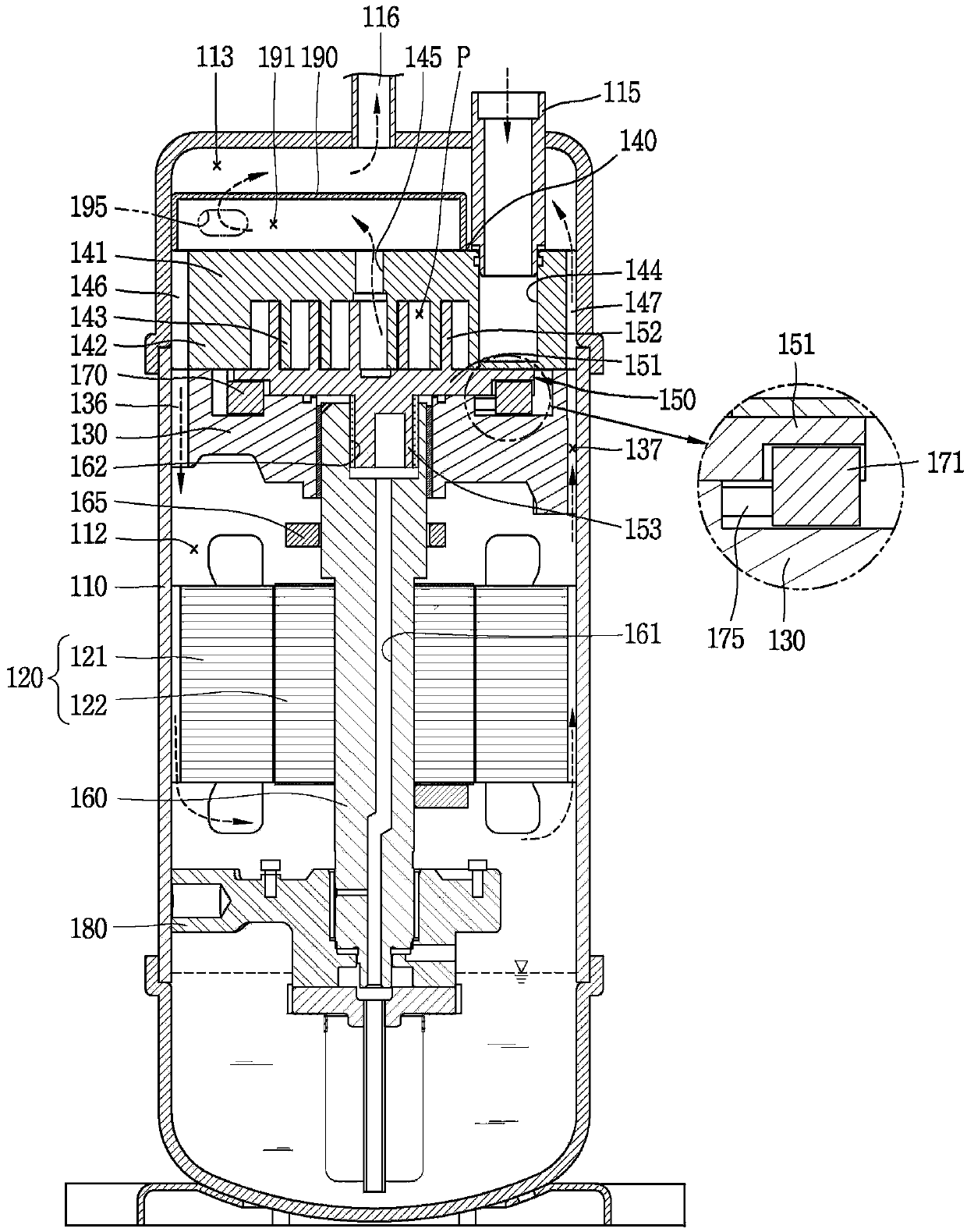

[0054] Hereinafter, the scroll compressor of the present invention will be described in detail based on an embodiment shown in the drawings.

[0055] figure 2 It is a longitudinal sectional view showing an example of the scroll compressor of the present invention.

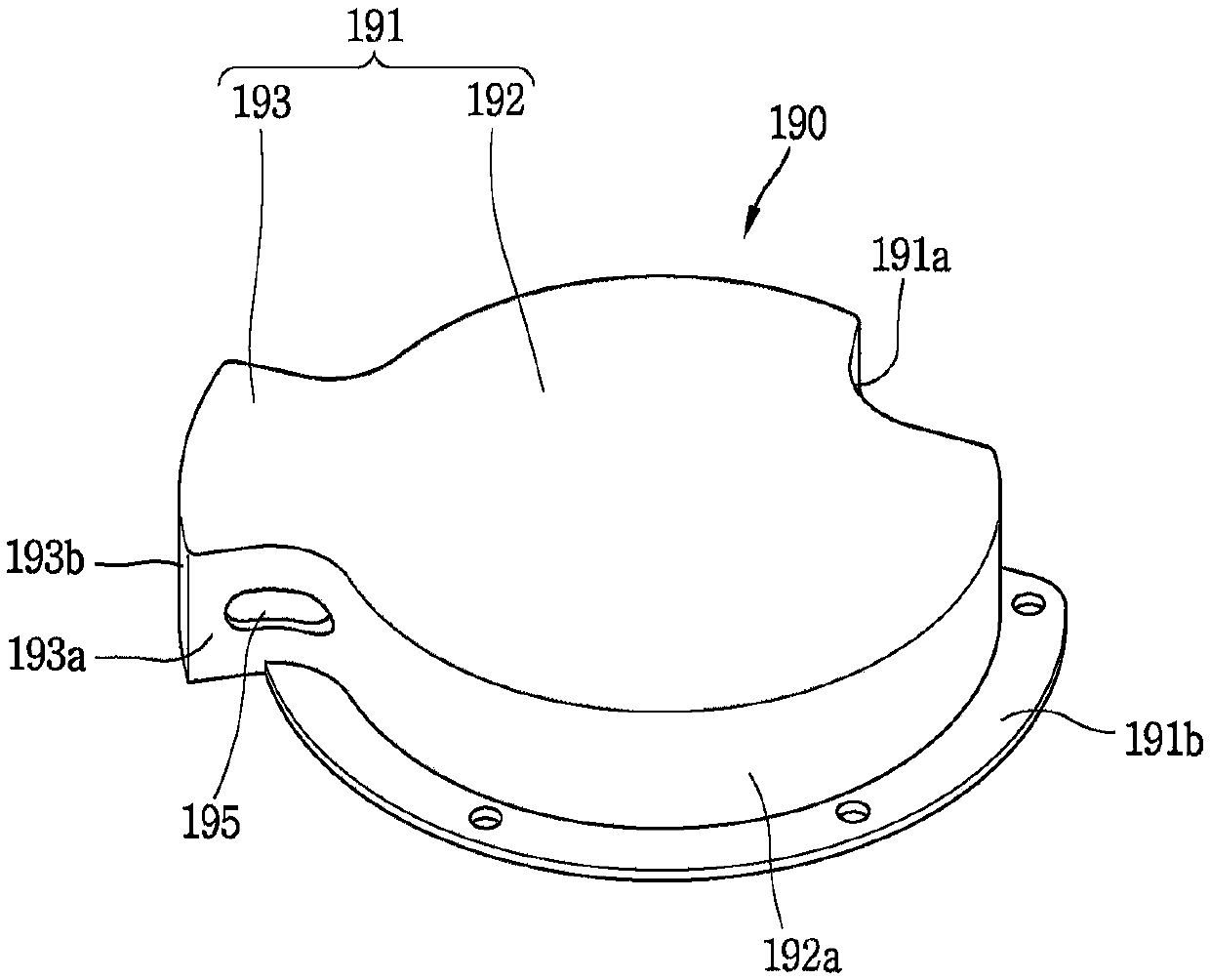

[0056] Such as figure 2 As shown, the internal space of the casing 110 of the scroll compressor of this embodiment is airtight, and the internal space can be divided into a motor space 112 in which a drive motor 120 described later is provided and a refrigerant discharged from a compression space described later. Oil separation space 113 from which oil is separated. However, the motor space 112 and the oil separation space 113 may communicate with each other through communication holes 146 , 147 and communication grooves 136 , 137 described later. Thus, part of the refrigerant discharged from the compression space P to the oil separation space 113 is discharged through the discharge pipe 116, and the other par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com